TP-6881 7/15114 Section 6 Disassembly/Reassembly

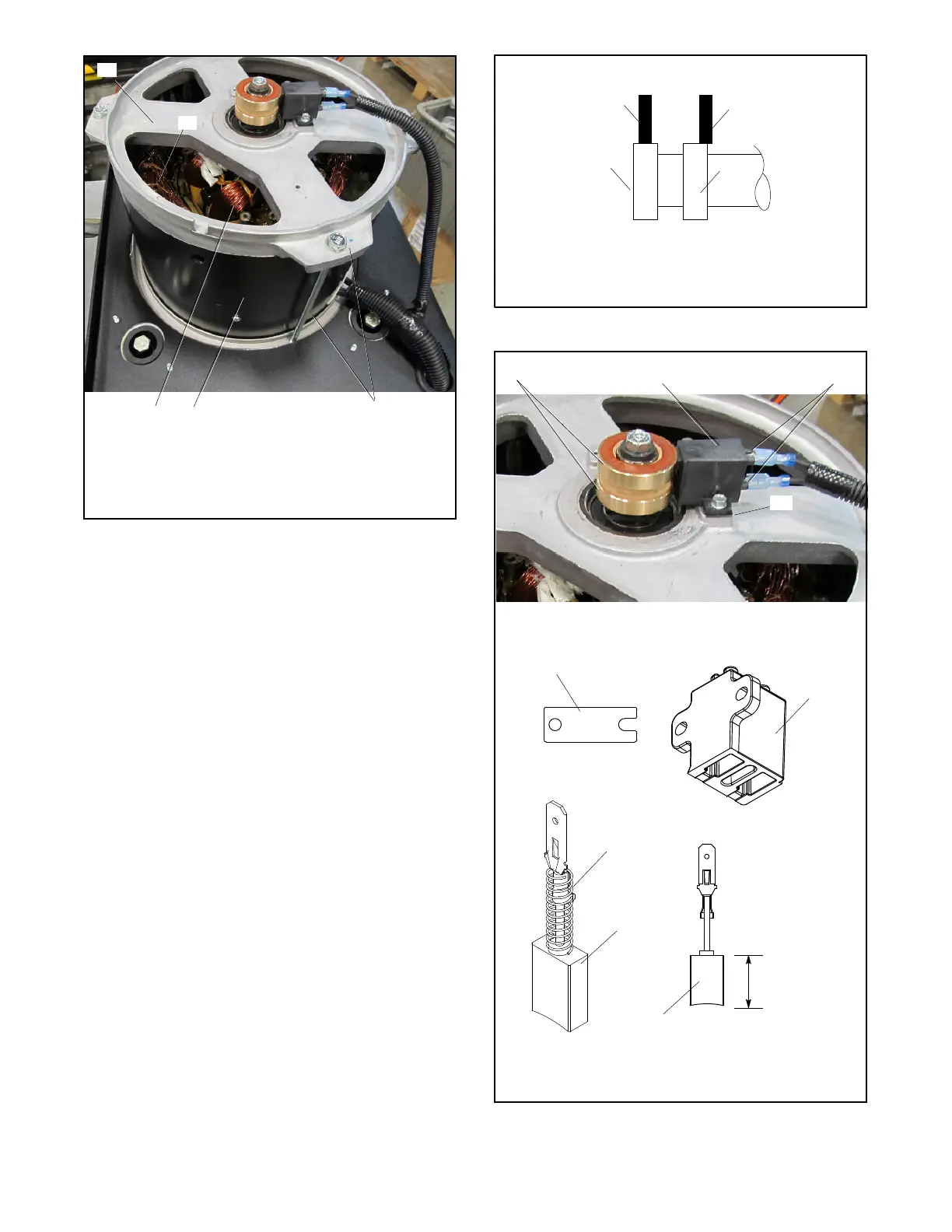

1. End bracket (brush assembly shown attached)

2. Stator windings (outer)

3. Rotor (inner). Also see Figure 6-13.

4. Stator shell

5. Overbolts (qty. 4)

1

3

4

5

2

Figure 6-14 End Bracket and Overbolt Assembly

6. Tighten the rotor thrubolt to 33 Nm (24 ft. lb.). It

may be necessary to keep the engine flywheel

from turning while torquing the rotor thrubolt.

7. Reinstall the end bracket components.

a. Inspect the brushes. If brushes show uneven

wear or are worn to less than half their original

length, replace them. See Section 5.7.

b. Install the brush holder with shim onto the end

bracket. Verify that the brushes are not sticking

in the holder.

c. Verify that the brushes are centered on the slip

rings. If required, insert spacers between the

mounting surface and brush holder to center

the brushes on the slip rings. See Figure 6-16.

See Section 5.7, Brushes, for more

information.

d. Use the cable tie to secure the brush leads to

the end bracket.

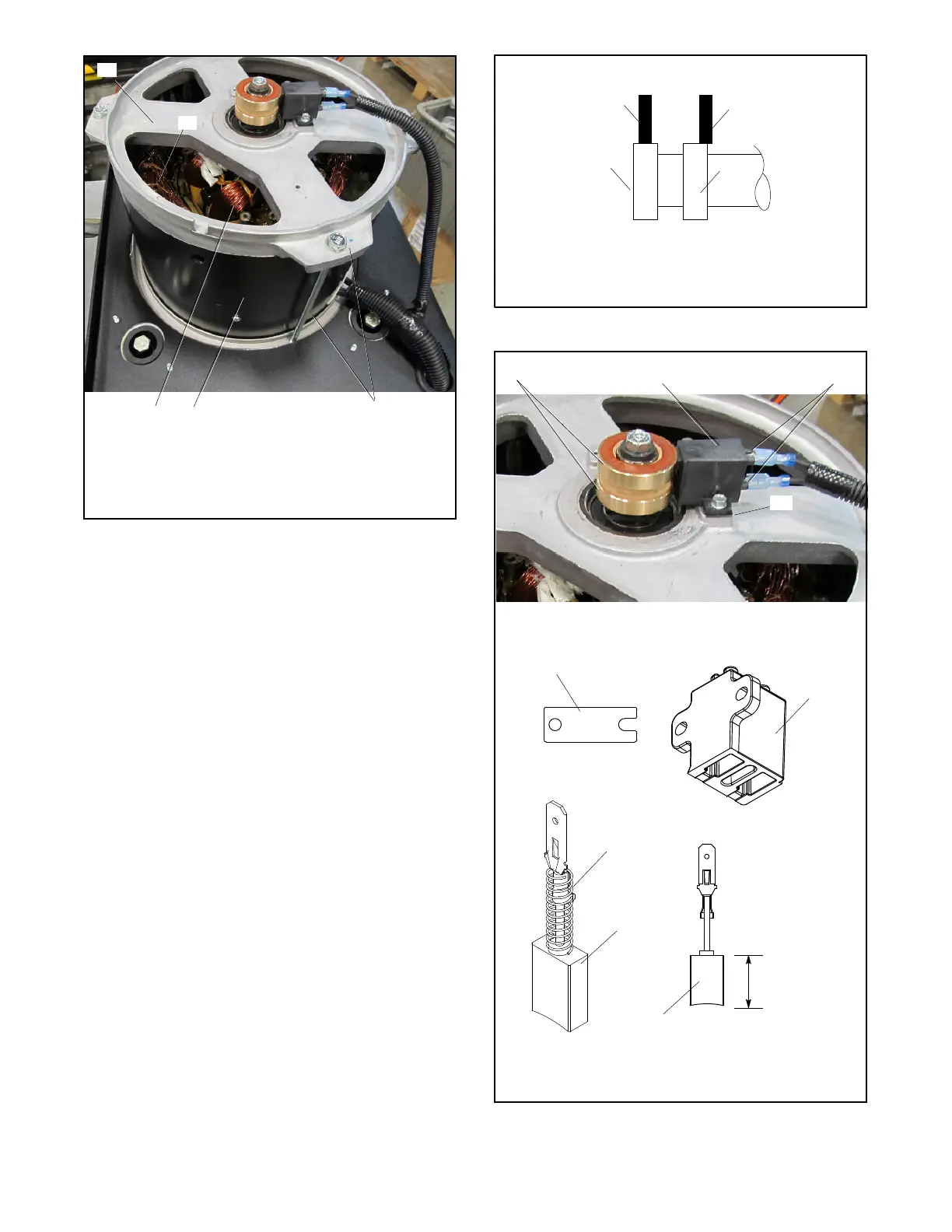

1. Correctly positioned brush

2. Incorrectly positioned brush

3. Slip rings

TP5867

Side View

1

2

3

3

Correct Incorrect

Figure 6-15 Brush Position

3

1. Slip rings

2. Brush holder

3. Brush(es)

4. Shim

5. Spring

GM80980

GM80981

Length New

19.0 mm

(0.75 in.)

Spring Not

Shown

5

3

3

GM80982

GM62996

2

4

1

4

2

Figure 6-16 Brush Assembly

Loading...

Loading...