DS4 C

HAPTER

2 - I

NSTALLATION

2-5

PSR4/5, and other equipment is accomplished by

connectors supplied with the BDS4 and PSR4/5 units.

The input/output connections are grouped by

connector or terminal block. They are input/output,

motor, resolver, AC main power and control voltages,

main DC bus, and unregulated DC voltages.

To connect the power bus of the PSR4/5 to the BDS4

amplifiers the following is suggested:

•

For PSR4/5-X12 modules, use 600 VAC

insulated 14 AWG or larger wire.

•

For PSR4/5-X20 modules, use 600 VAC

insulated 10 AWG wire.

•

For PSR4/5-50 and PSR4/5-75 modules, use

600 VAC insulated 8 AWG or larger wire.

Captive screws are used in the power terminals of the

PSR4/5-X12 module, PSR4/5-X20 module, and the 3

amp thru the 20 amp BDS4 amplifiers. Do not

attempt to remove these screws to use ring terminals.

Use locking spring terminals similar to Hollingsworth

#XSS20945S or #SS20947SF for 16 and 14 AWG

wire and #XSS20836 or #SS20832F for 12 and 10

AWG wire.

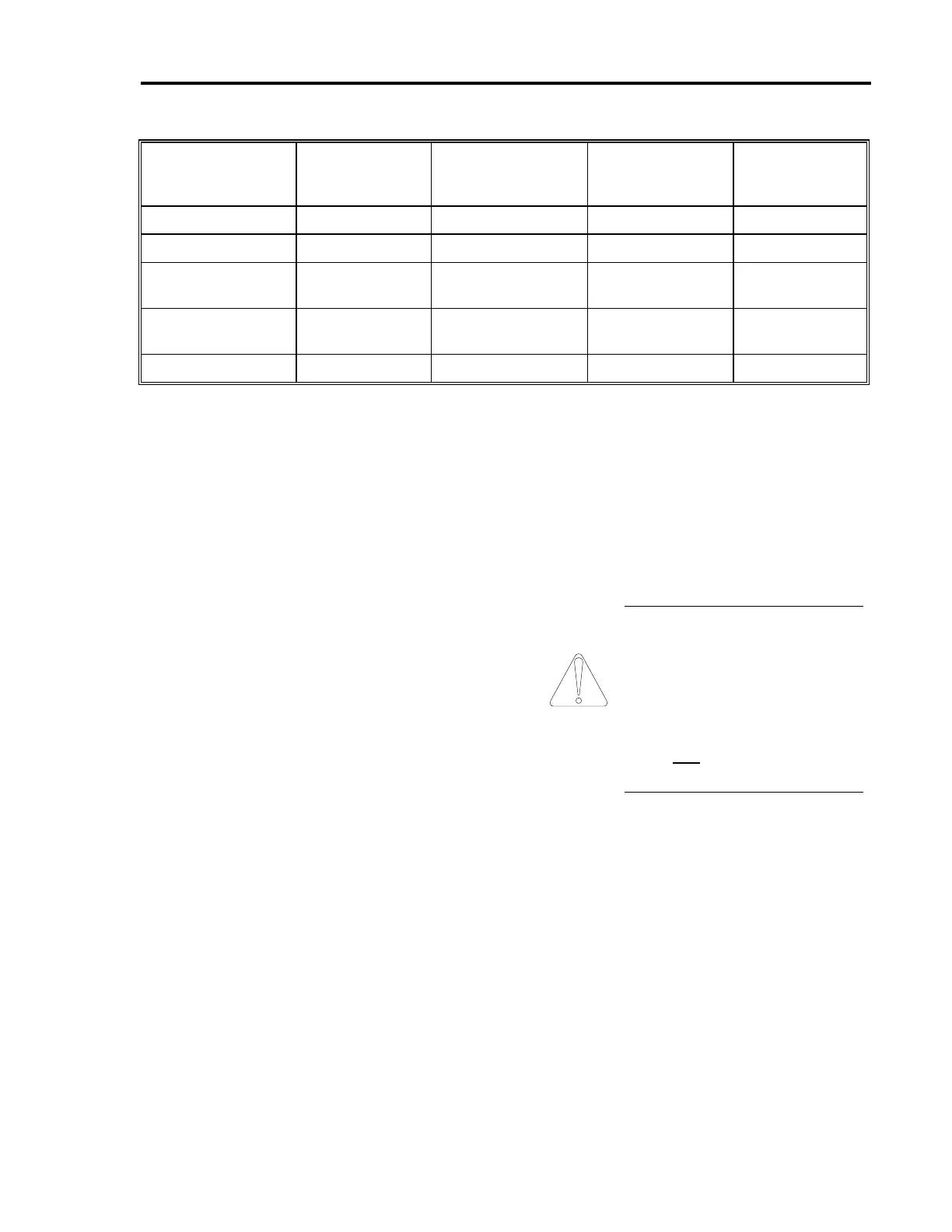

2.7.1 Recommended Torque for

Electrical Connections

Table 2.1 displays the recommended torque values

for terminal block and grounding connecting points.

All torques are measured with the wire or terminal lug

underneath the screw head.

2.7.2 Grounding Scheme

To prevent shock hazard to personnel and to ensure

proper operation of the servo system, the BDS4,

PSR4/5, and the servo motor must be grounded

according to NEC specifications. Each BDS4 and

PSR4/5 have at least two grounding screws on the

front of the chassis.

NOTE

Provisions of the National

Electrical Code with respect

to grounding should be

followed. These precautions

generally deal with the

ground loop currents arising

from multiple ground paths.

Only one ground path should

be used.

One of the screws on the chassis of the PSR4/5

should go to earth or machine ground. The other

should be connected to the adjacent BDS4 ground

screw along with the ground wire from the motor.

The free ground screw on the BDS4 chassis should

then be connected to the next BDS4, etc.

For grounding to machine or earth ground, a screw

lug should be attached to the ground screw or stud on

the PSR4/5 or BDS4. A torque of 12 in.lb. for

ground screws and 20 in.lb. for ground studs is

recommended. Also refer to the National Electrical

Code (NEC) or UL standard 486B for recommended

torque's.

Table 2.1. Torque Values

CONNECTING

POINTS

BDS4-3-20

AMP UNITS

BDS4-30-55

AMP UNITS

PSR4/5-12-20

AMP UNITS

PSR4/5-50-75

AMP UNITS

AC Input Screws 12 in. lb. 20 in. lb. 12 in. lb. 20 in. lb.

DC Bus Screws 12 in. lb. 20 in. lb. 12 in. lb. 20 in. lb.

Motor Connecting

Screws

12 in. lb. 20 in. lb.

External Regen

Screws

12 in. lb. 20 in. lb.

Ground Screws 12 in. lb. 20 in. lb. 12 in. lb. 20 in. lb.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...