21. STANDARD TIGHTENING TORQUES

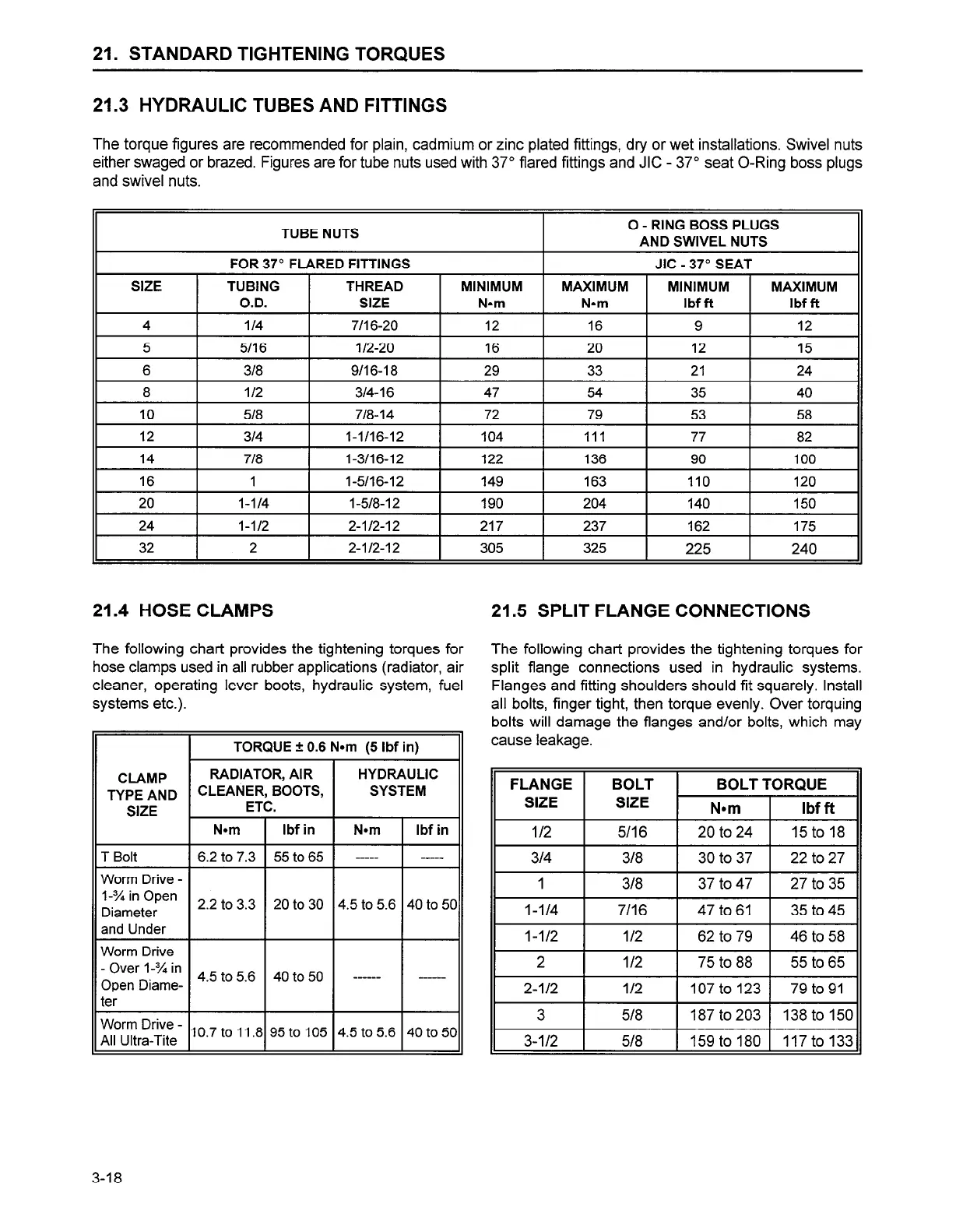

21.3 HYDRAULIC TUBES AND FITTINGS

The torque figures are recommended for plain, cadmium or zinc plated fittings, dry or wet installations. Swivel nuts

either swaged or brazed. Figures are for tube nuts used with 37” flared fittings and JIC - 37” seat O-Ring boss plugs

and swivel nuts.

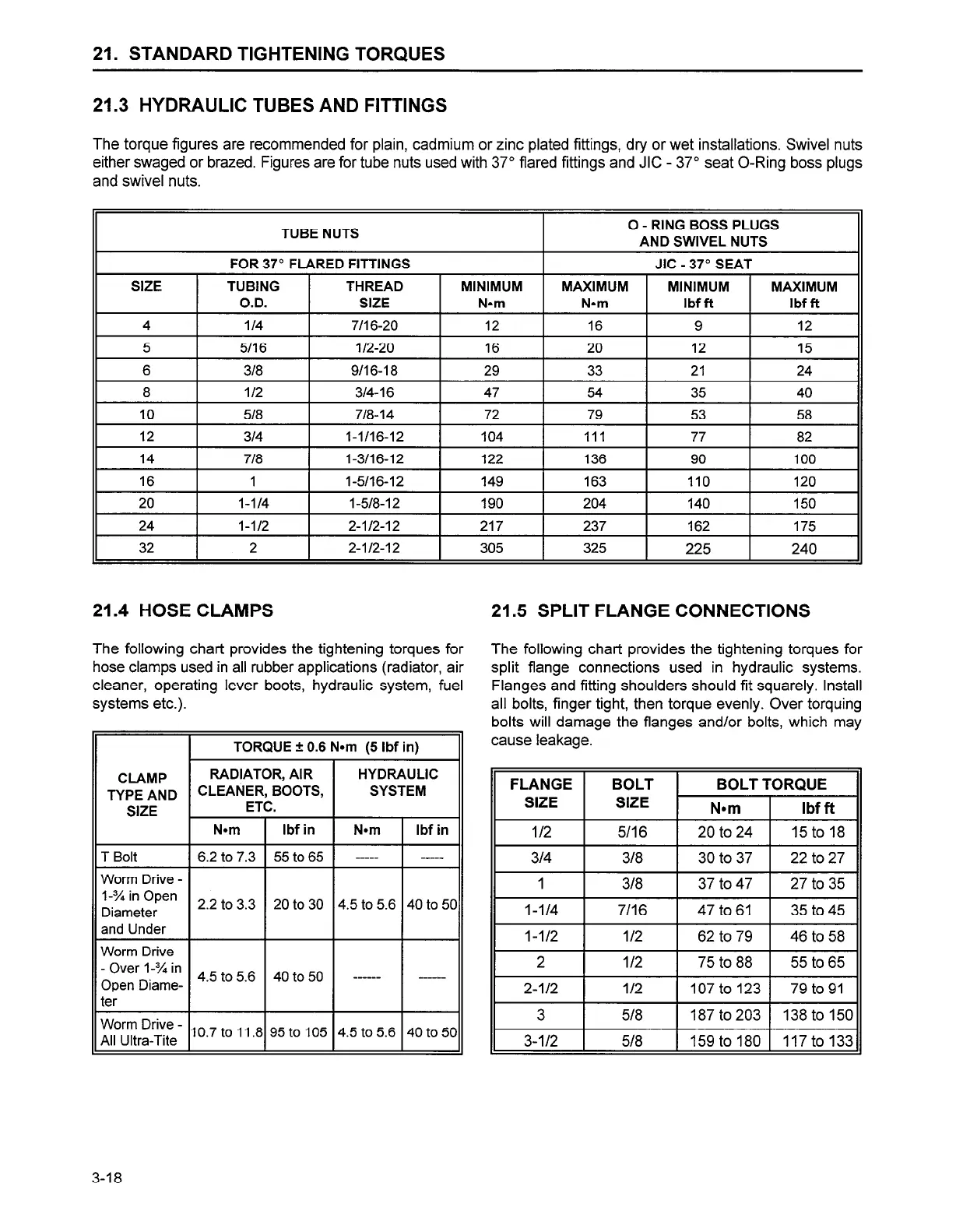

21.4 HOSE CLAMPS 21.5 SPLIT FLANGE CONNECTIONS

The following chart provides the tightening torques for

hose clamps used in all rubber applications (radiator, air

cleaner, operating lever boots, hydraulic system, fuel

systems etc.).

The following chart provides the tightening torques for

split flange connections used in hydraulic systems.

Flanges and fitting shoulders should fit squarely. Install

all bolts, finger tight, then torque evenly. Over torquing

bolts will damage the flanges and/or bolts, which may

cause leakage.

I

TORQUE f 0.6 Nom (5 Ibf in)

CLAMP

RADIATOR, AIR

TYPE AND

CLEANER, BOOTS,

SIZE

HYDRAULIC

SYSTEM

Nom 1 Ibf in

T Bolt

Worm Drive -

1-X in Open

Diameter

and Under

Worm Drive

- Over 1-X in

Open Diame-

ter

Worm Drive -

All Ultra-Tite

6.2 to 7.3

2.2 to 3.3

4.5 to 5.6

10.7 to 112

55 to 65

20 to 30

40 to 50

95 to 105

4.5 to 5.6

4.5 to 5.6

-_--_

40 to 51

40 to 5(

FLANGE

SIZE

112

BOLT

SIZE

5/l 6

BOLT TORQUE

Nom Ibfft

20 to 24 15tol8

II

314

I

318 1 30 to 37 1 22 to 27 11

1 318 37 to 47 27 to 35

l-l/4 7116 47 to 61 35 to 45

l-l/2 II2 62 to 79 46 to 58

II 2 I “2

l 75 to 88 1 55 to 65 11

3-l 8

Loading...

Loading...