SEN03837-01

30-120 26 WA250, 250PZ-6

120 Testing and adjusting, Part 2

Bleeding air from wheel brake circuit

Bleeding air from wheel brake

circuit

1

Necessary tools

k Stop the machine on a level ground, lower

the work equipment to the ground, and set

chocks under the tire securely.

a If a brake circuit part is removed and installed,

bleed air from the brake circuit according to the

following procedure.

a Bleed air from the front brake circuit and rear

brake circuit similarly (2 places each).

a When a complete bleeding is required, it is

advisable to start the operation from the brake

cylinder situated farthest from the brake pedal.

a The work on the front right side is shown as an

example. Work on each brake cylinder simi-

larly.

1. Start the engine to accumulate pressure in the

accumulator and then stop the engine.

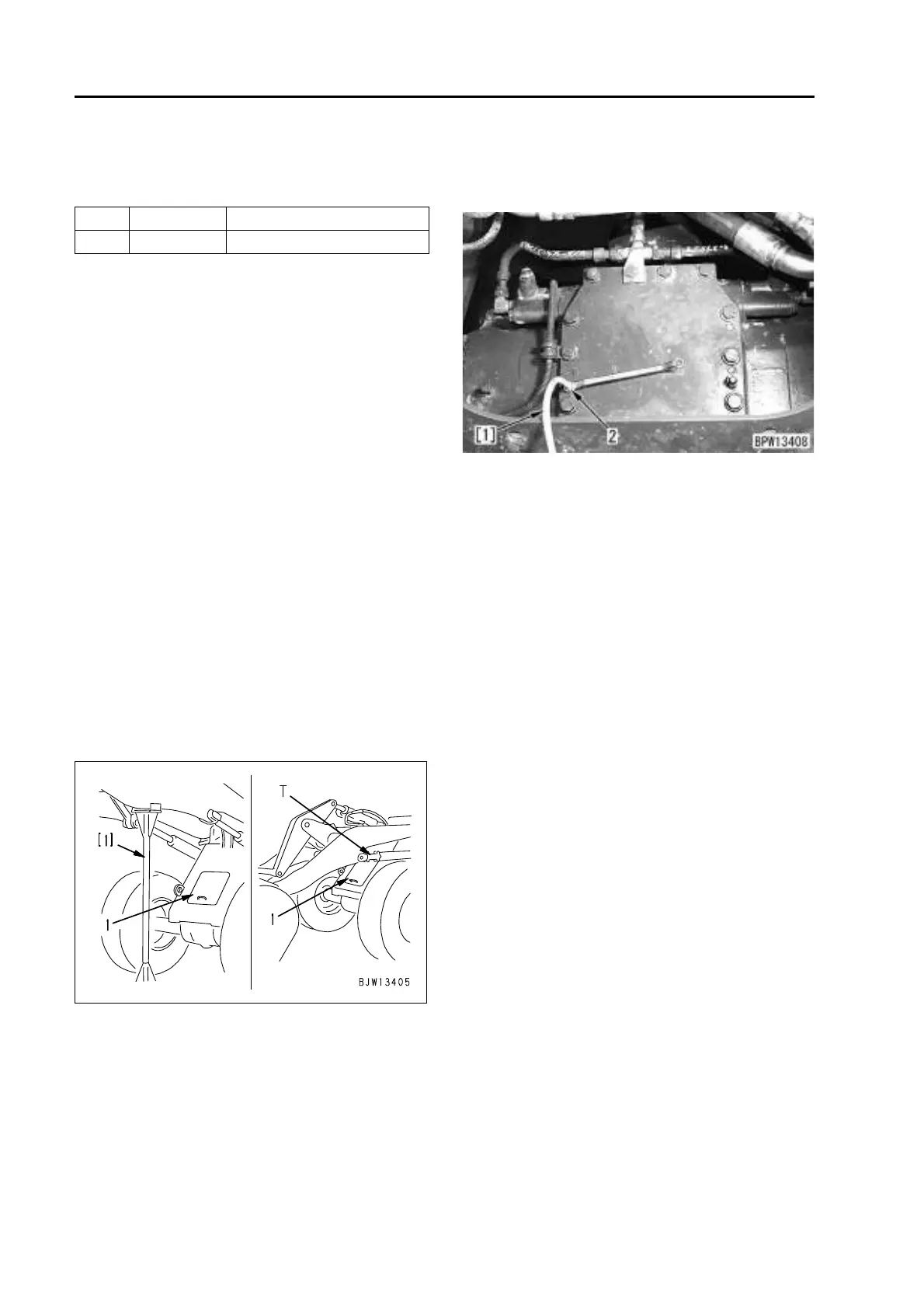

2. Remove front frame inspection cover (1).

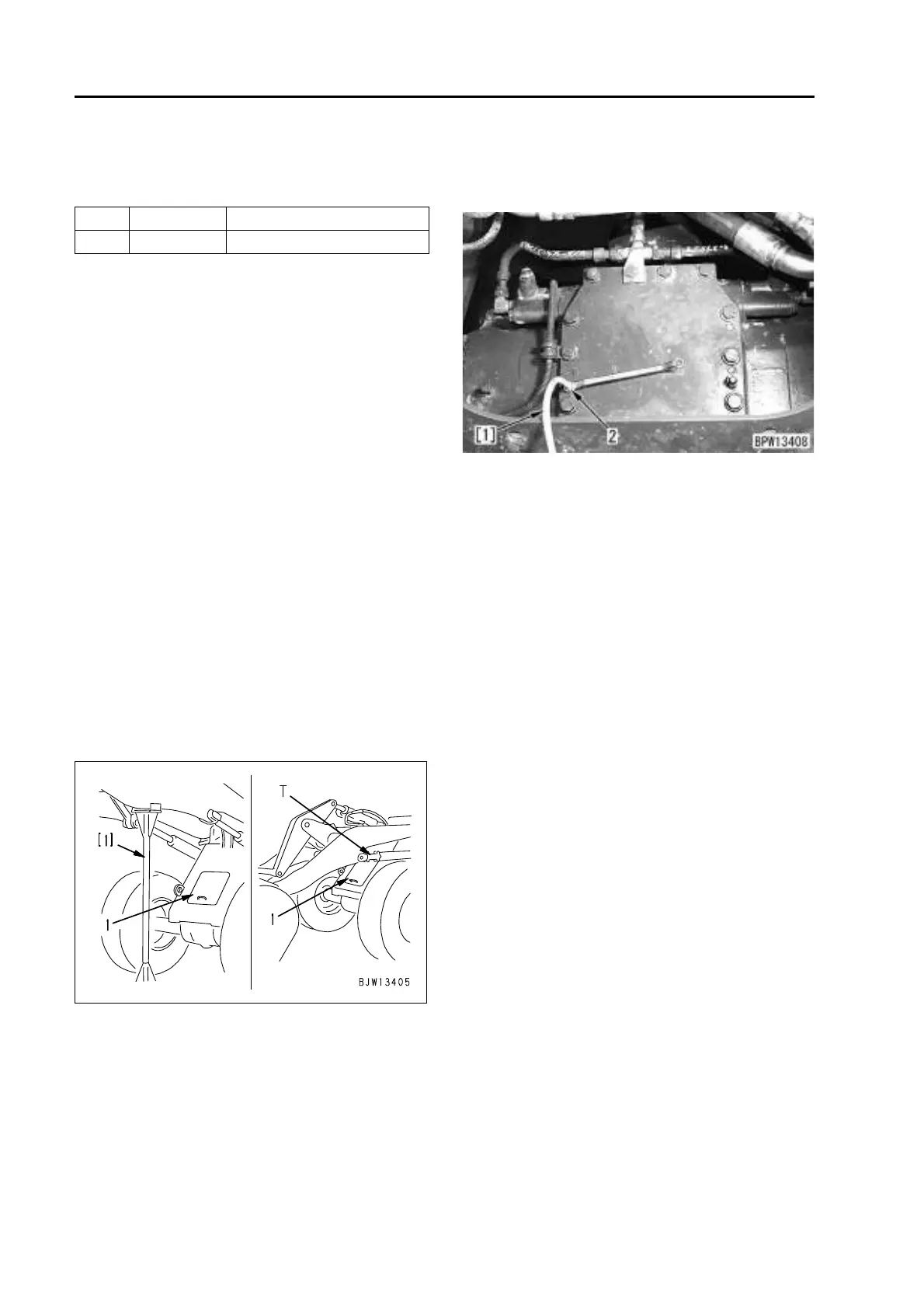

k When raising the lift arm and removing

the inspection cover, place support

stand [1] under the lift arm to support

the lift arm securely or set stopper T to

the lift arm cylinder to prevent the work

equipment from falling.

3. Connect hose [1] to bleeder screw (2) and

place hose [1] in the oil receive pan.

a Work on the rear side similarly from under-

side of the machine.

4. Press the brake pedal and then loosen bleeder

screw (2) to bleed air.

a Return the brake pedal slowly after tight-

ening bleeder screw (2).

5. Repeat this operation until the oil flowing

through hose [1] becomes free from bubbles.

Then press the pedal fully and tighten bleeder

screw (2) while the oil is flowing.

a As accumulated pressure in the accumu-

lator is decreased, start the engine to

accumulate pressure in the accumulator.

Then bleed air using the same procedure

as described above.

a After finishing bleeding air, run the engine

at low idle and check the oil level in the

hydraulic tank. If the level is low, add oil up

to the specified level.

6. After finishing the work, remove the measuring

instruments and return the removed parts.

Symbol Part No. Part name

T 793-403-1100 Stopper

Loading...

Loading...