5.8 Maintenance procedure

Maintenance every 250 service hours Maintenance

5-50

WA80M-7, WA100M-7 – VENAM03001

Rear axle – lubricating

Shorten the maintenance intervals if working continuously in wet

or salty environments.

Performing maintenance on a machine that is not properly

parked and secured may cause severe accidents!

Park the machine on solid, level ground. Secure the machine

before beginning maintenance work.

1. For maintenance work, park the machine as described in

chapter “Maintenance guide (5-2)”.

2. Clean the indicated grease nipple.

3. Use a grease pump to press a sufficient amount of grease into

the grease nipples.

4. Remove any excess old grease that is pushed out at the bear-

ings.

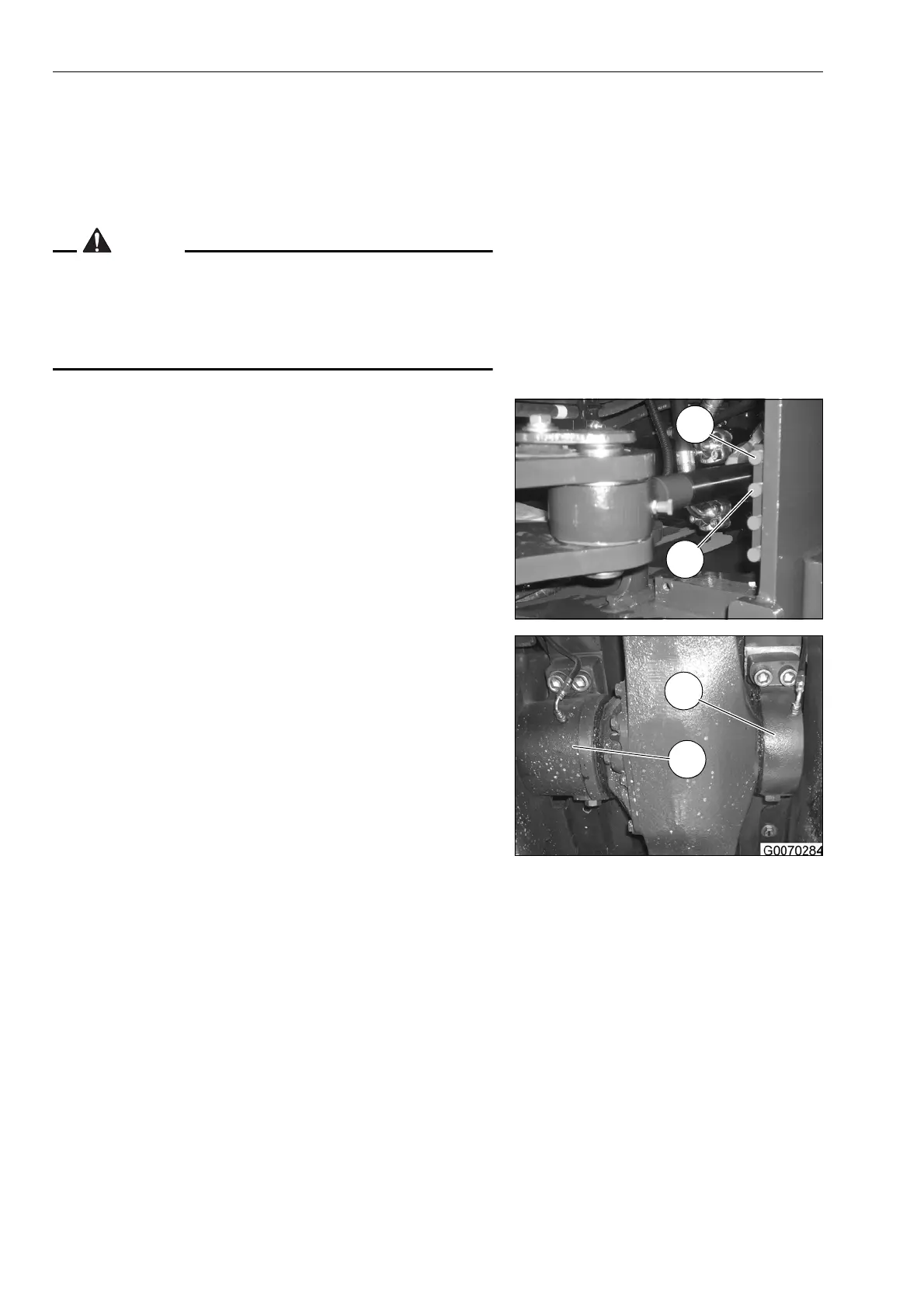

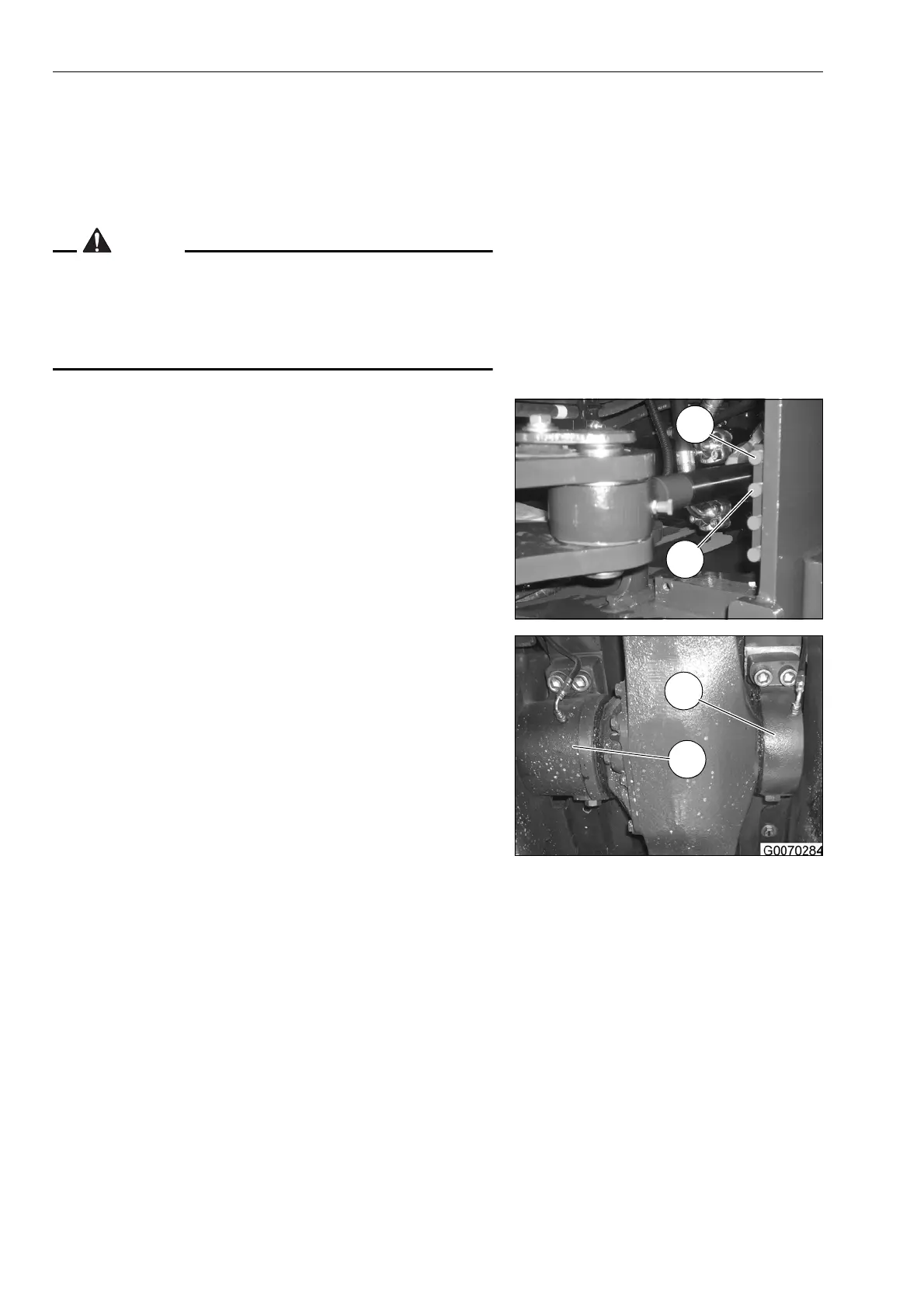

Rear axle pivot bearing (1) (2).

Wheel nuts – checking and retightening

For details see “Wheel nuts – checking and retightening (5-40)”.

Loading...

Loading...