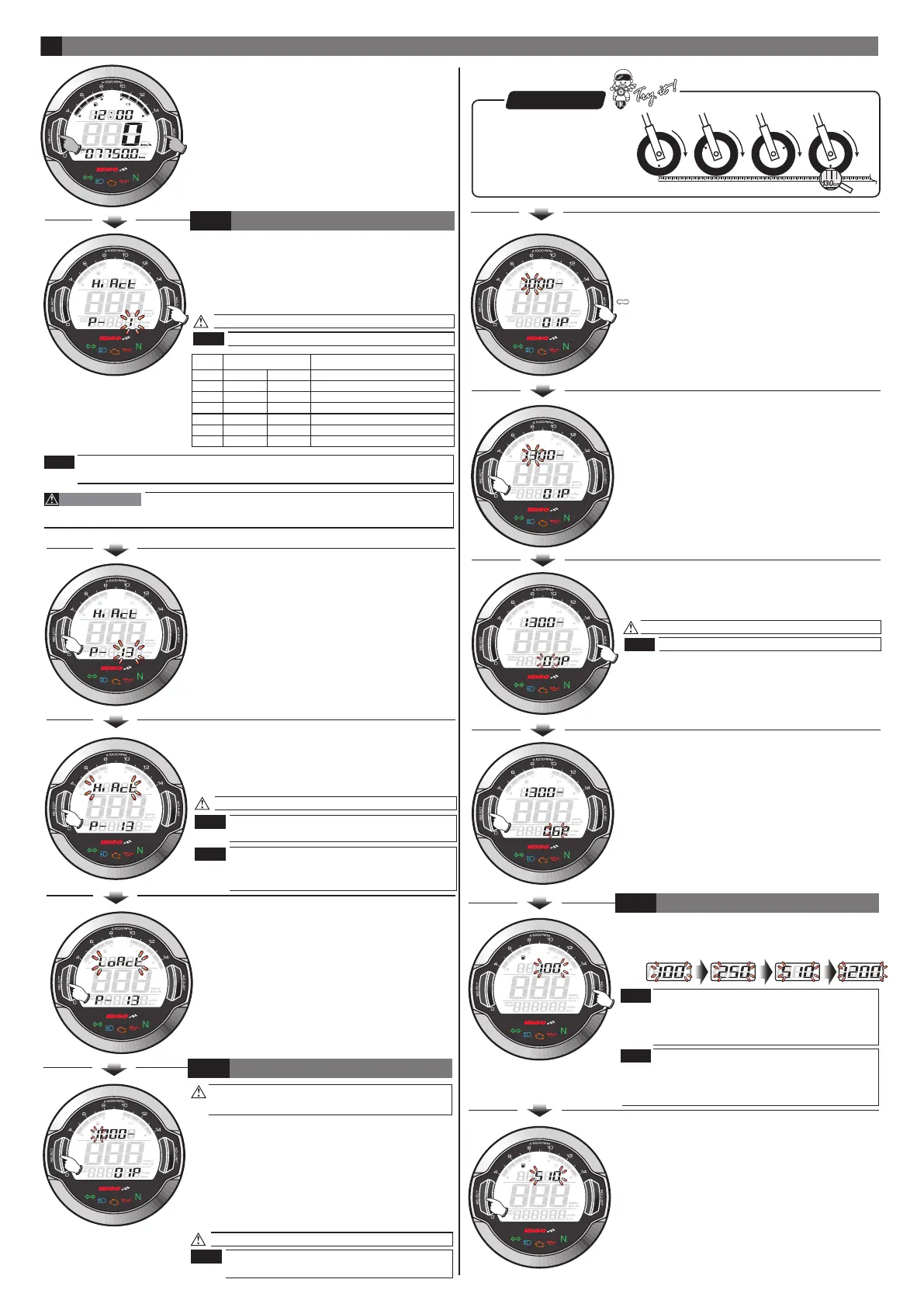

●In main screen, Hold pressing the Select &

Adjust button for 3 seconds to enter the

setting screen.

Now the digit under setting is flashing!

Setting range: 0.5,1 ~24.

●Then press the Adjust button to change

the setting value.

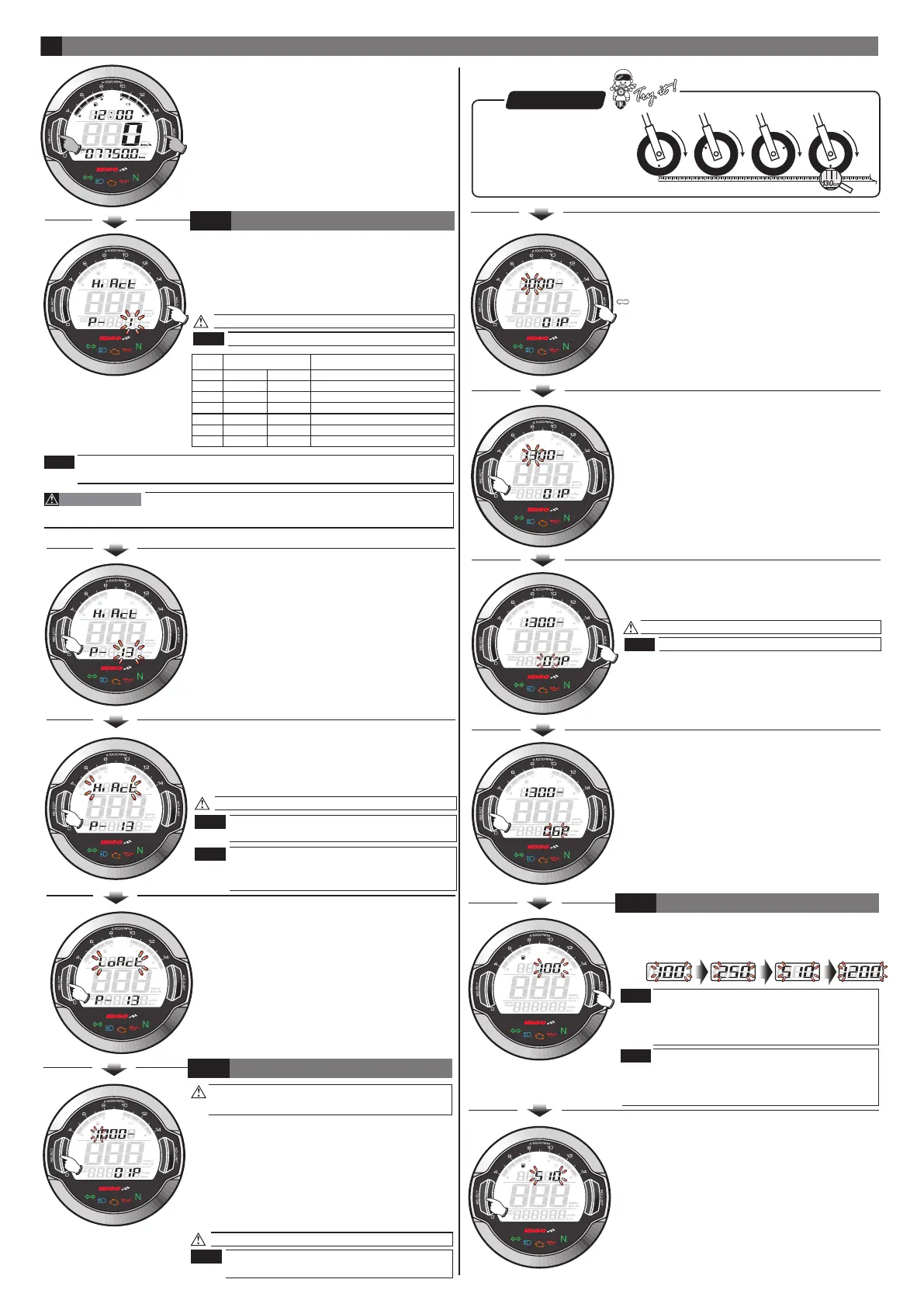

●After the setting, keep pressing the Select

button one time to enter the sensor point

setting.

●EX. The tire circumference adjust setting is

changed from 1000 mm to 1300 mm.

●After the setting, keep pressing the Select

button one time to enter the fuel resistance

setting.

●EX. The sensor point setting is changed from

01P~06P.

Now the sensor point setting is flashing!

Setting range: 1~20 point.

●EX. The sensor point you want to set is 06P.

●Press the Adjust button to change the setting.

●EX. New the sensor point setting is 01P.

4

●EX. You want to connect the RPM signal wire

to the pick up signal and there are 13

flywheel signals per turn.

●Press the Adjust button to change the setting.

●EX. Now the current input signal setting is 1.

4-1

EnteringENTERING SETTING SCREEN

The RPM input signal setting

wh642bb03b-P4-3

NOTE

NOTE

●Press the Select button one time to enter

the input pulse setting.

●EX. Now the RPM input signal number setting

is changed from 1 to 13.

●After the setting, keep pressing the Select

button one time to enter the tire

circumference compensation setting.

●EX. Now the input pulse setting changed

from is Hi to Lo.

●EX. We want to change the setting to Hi.

(The negative signal pulse.)

●Press the Adjust button to choose waveforms

you would like to set.

●EX. Now the current setting is Hi.

Now the pulse setting is flashing!

We define the RPM input pulse as Hi (The

positive pulse) & Lo (The negative pulse.)

If the RPM displayed on the meter is

incorrect or with noise, please choose

another setting and try it again.

NOTE

NOTE

●You could define the valve

as the starting point and the

terminal point to measure

the wheel circumference

with a measuring tape.

P.S.

●After the setting, keep pressing the Select

button one time to enter the clock setting.

●EX. The fuel resistance setting is changed

from 100 to 510.

The fuel gauge resistance setting range:

100Ω、250Ω、510Ω、1200Ω

If you don’t install the fuel wiring, the fuel

gauge will not display.

●EX. The fuel gauge need to be set to 510Ω

●Press the Adjust button to choose the setting

number.

.

When Fuel Resistance Setting is changed, the

4-3

THE FUEL RESISTANCE SETTING

NOTE

NOTE

remaining Mileage will be reset to 0 and have to

restart the learning process. About the Learning

process please refer to the instruction from 3-5.

For most of Injection Model, setting value might exceed 6 if RPM connection

method B is chosen, and it depend on the number of the bump it has on its

flywheel.

●EX. The new tire circumference is 130 cm.

The calculation equation is as below.

●The new tire circumference (130 cm) ÷

the original tire circumference (125 cm)

X 100 %= The setting value (104 %).

●Please keep pressing the Select button

and release it until it move to the setting

digital you want.

●EX. The original setting is 1000.

Now the setting digital value is flashing!

Setting range: 300~2500.

Setting unit: per 1 %.

Please reset this setting value when you

change a different size tire.

4-2

THE TIRE CIRCUMFERENCE COMPENSATION SETTING

NOTE

Setting

value

2 RPM signals per 1 spark.

1 RPM signal per 1 spark.

1 RPM signal per 2 sparks.

2 RPM signals per 10 sparks.

1 RPM signal per 3 sparks.

1 RPM signal per 4 sparks.

1 RPM signal per 6 sparks.

Most of the 4-cycle bikes with one single piston are igniting

every 360 degree once, so the setting should be the same as the bike with

2-cycle and one piston engine.

CAUTION!

NOTE

2 strokes

setting

4 strokes

setting

RPM per spark

1 piston

2 pistons

4 pistons

6 pistons

8 pistons

10 pistons

12 pistons

1 piston

2 pistons

3 pistons

4 pistons

6 pistons

0.5

1

2

3

4

5

6

Loading...

Loading...