BA 35101/02/ 03 EN – Edition 1.0 * 35101_02_03b510.fm 5-19

Maintenance

5.9 Lubrication work

General safety instructions regarding lubrication work

• Park the wheel loader on level ground and prevent it from rolling away by applying the

parking brake and placing wheel chocks

• Raise the loader unit and secure it with the safety strut on the lift ram

• Stop the engine and remove the ignition key

Lubricate all lubrication points mentioned below with lithium-saponified brand-

name grease

☞ –seeFluids and lubricants on page 5-43

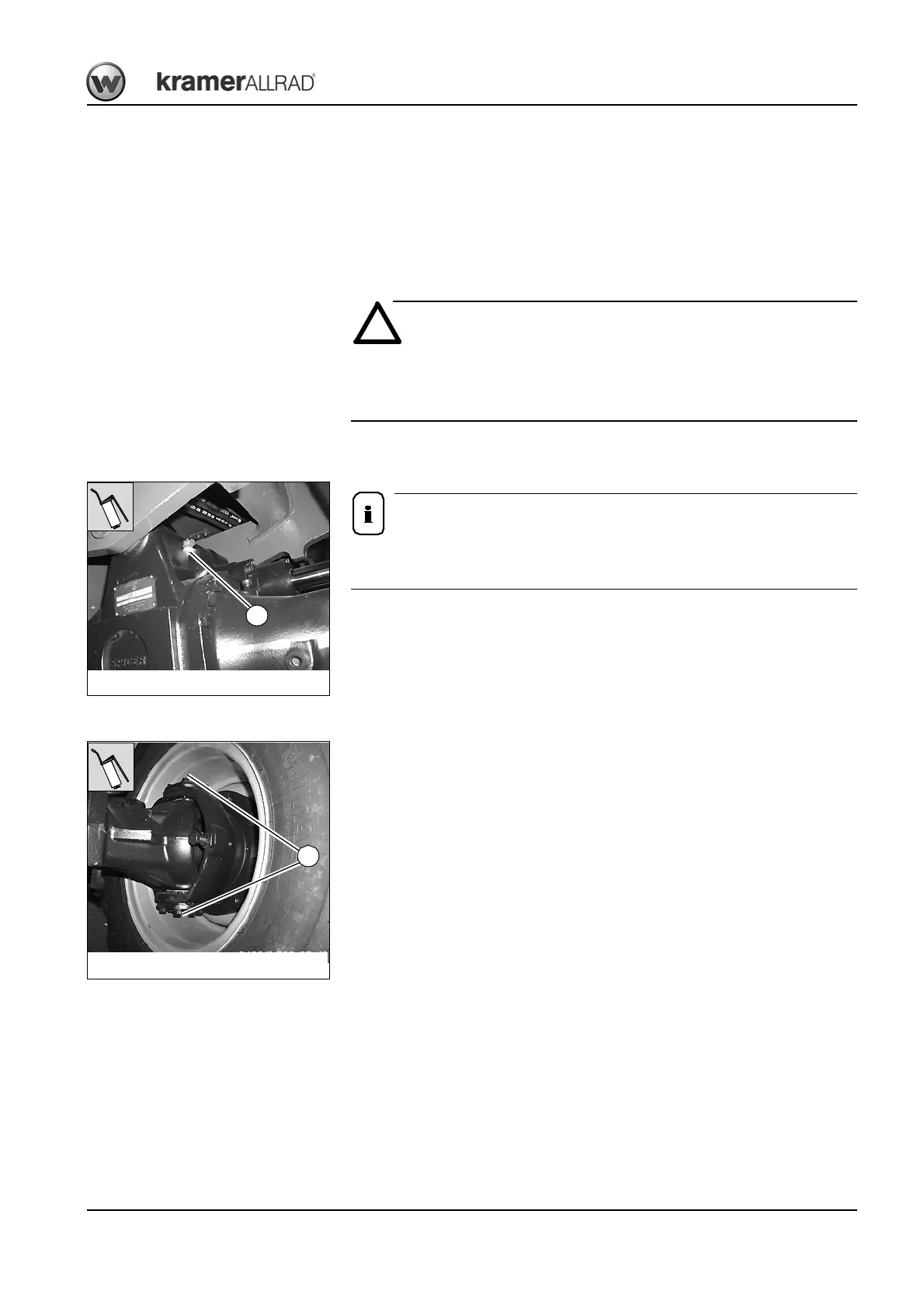

Lubricating the rear axle oscillation-type bearing

The machine has an oscillation-type rear axle. Lubricate the bearing every 20

service hours at the latest.

☞ Lubricate grease nipple A of the oscillation-type bearing

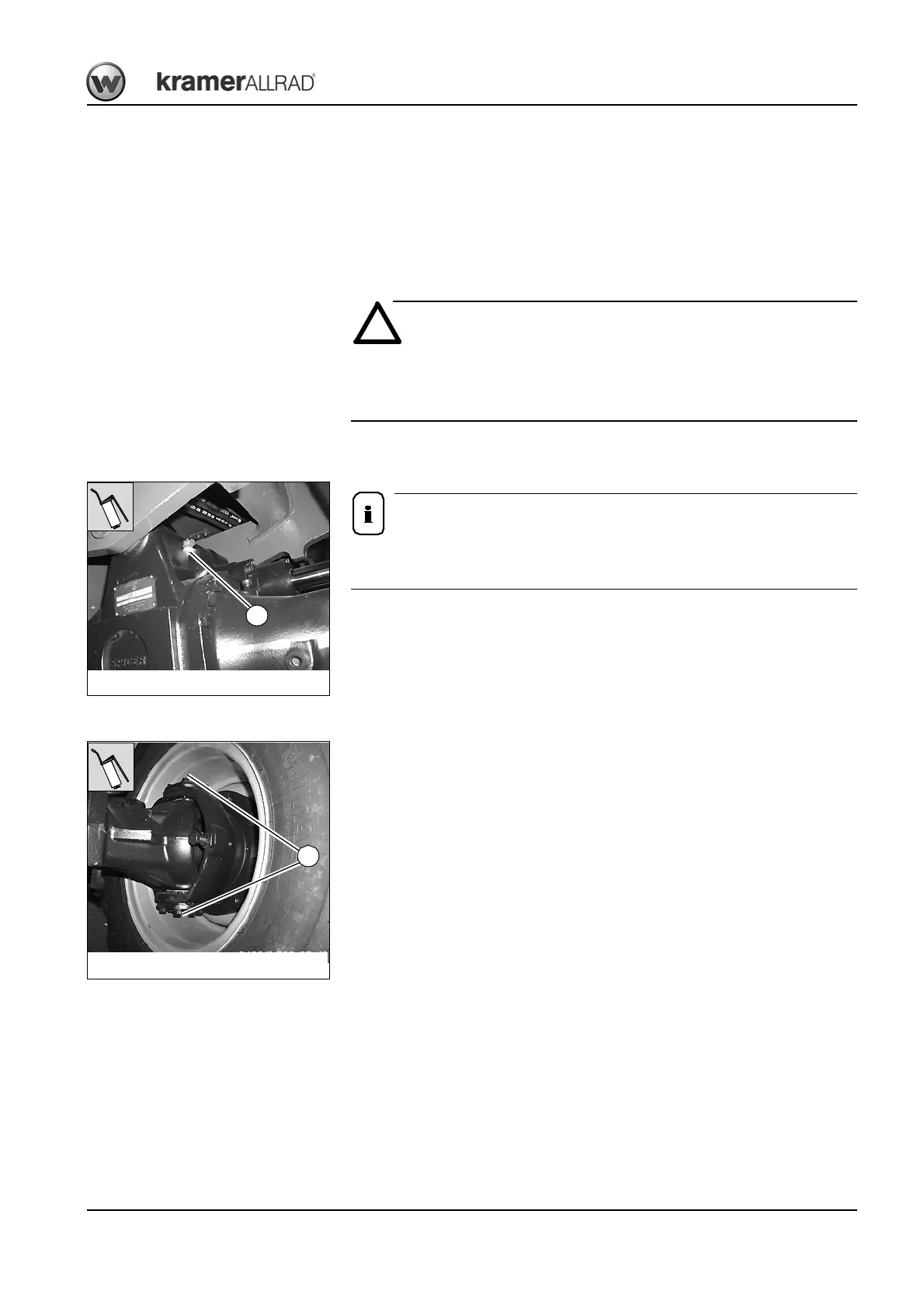

Lubricating the front and rear axle planetary drive bearings

☞ Lubricate grease nipples B (2 x) on each planetary drive bearing every 20 service

hours

Fig. 173: Grease nipples for oscillation-type bearing

A

Fig. 174: Grease nipples on planetary drive bearings

B

Loading...

Loading...