Positioning the Mini Kreg Jig

®

to center a screw in various material thicknesses is

accomplished by setting the base of the jig a given distance from the edge of the

workpiece. (Be sure to clamp the jig to the workpiece before drilling)

Using the Mini Kreg Jig®

3-5/16”

3-1/2”

4-1/4”

1/2

3/4

1.5

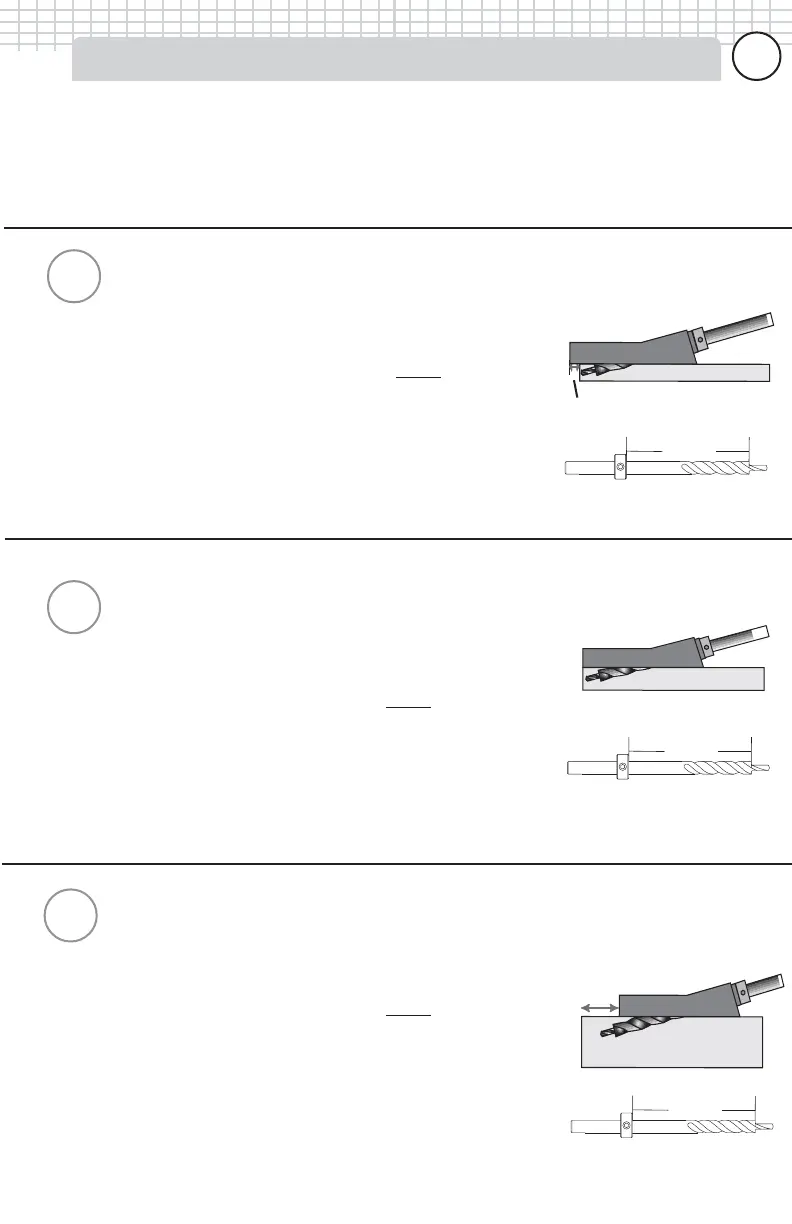

To join 1/2” thick material.

1. Clamp the workpiece to be drilled to a stationary object

such as a workbench.

2. Set depth collar to 3-5/16” from the

STEP

of the drill bit.

3. Position the base of the jig 3/8” over the edge of the

workpiece as shown at right. Clamp jig to material with

Face Clamp

TM

.

4. Drill pocket hole. Use 1” screw to join 1/2” to another

1/2” thick workpiece.

To join 3/4” thick material.

1. Clamp the workpiece to be drilled to a stationary object

such as a workbench.

2. Set depth collar to 3-1/2” from the

STEP

of the drill bit.

3. Position the base of the jig flush with the edge of the

workpiece as shown at right. Clamp jig to material with

Face Clamp

TM

.

4. Drill pocket hole. Use 1-1/4” screw to join 3/4” to

another 3/4” thick workpiece.

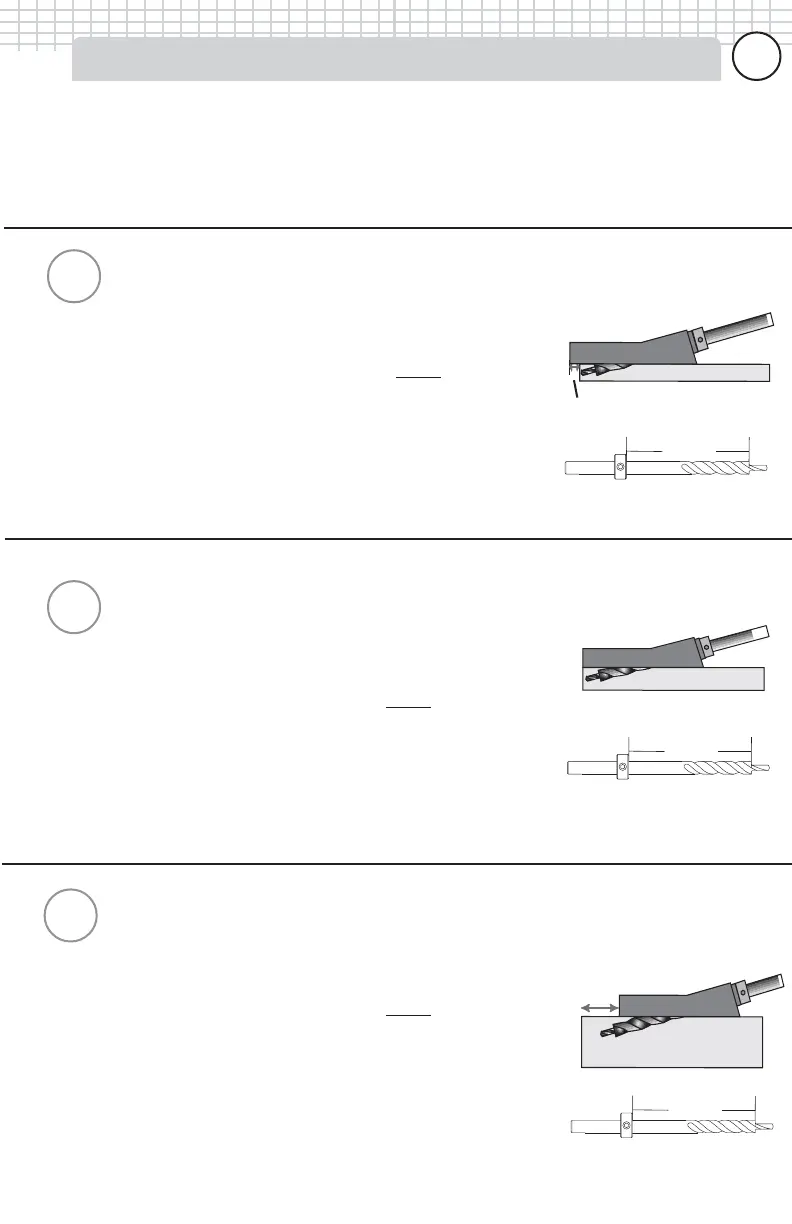

To join 1-1/2” thick material.

1. Clamp the workpiece to be drilled to a stationary object

such as a workbench.

2. Set depth collar to 4-1/4” from the

STEP

of the drill bit.

3. Measure and set the base of the jig back 1-1/4” from

the edge of the workpiece as shown at right. Clamp jig

to material with Face Clamp

TM

.

4. Drill pocket hole. Use 2-1/2” screw to join 1-1/2” to

another 1-1/2” thick workpiece.

Figure

(19)

Figure

(20)

Figure

(21)

1414

1414

14

4-1/4”

1-1/4”

3/8”

Loading...

Loading...