2626

2626

26

Steps to Building an Angled Joint

1. Plane stiles to same thickness, rip to width and cut square to length.

Place desired angle on inside edge of one stile.

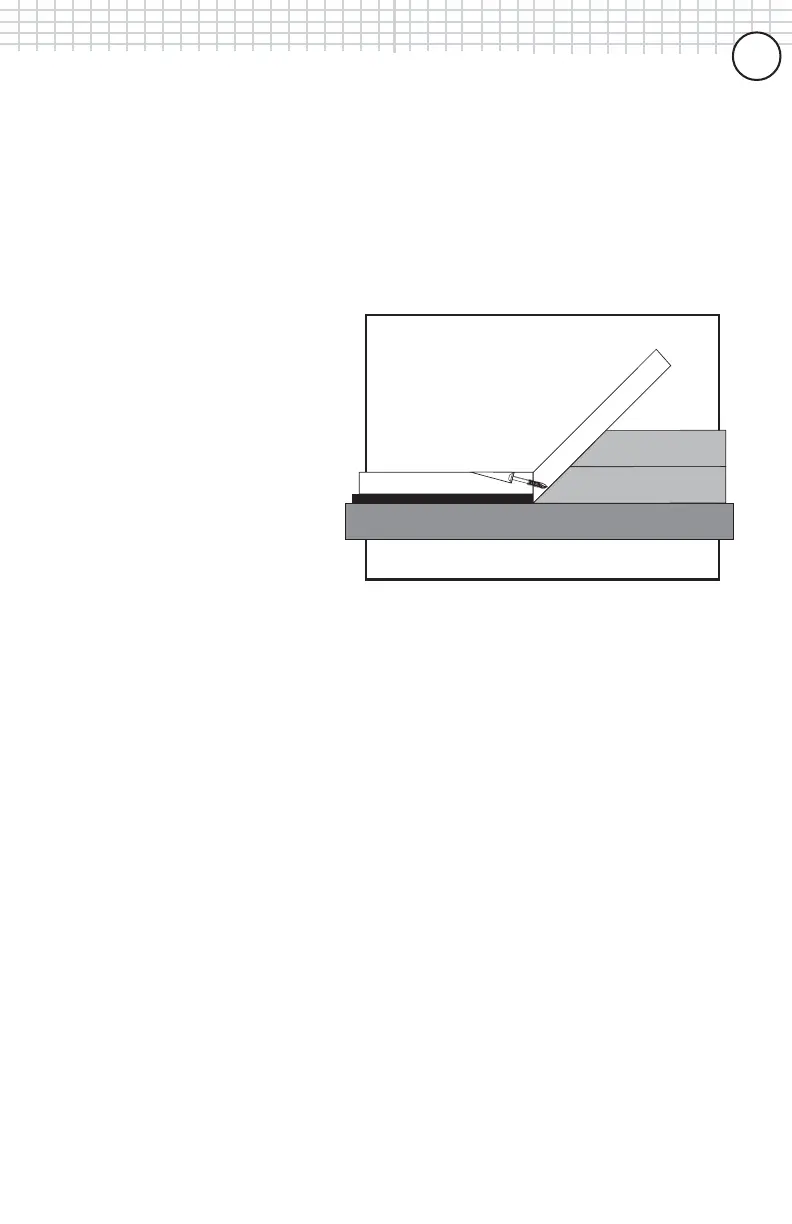

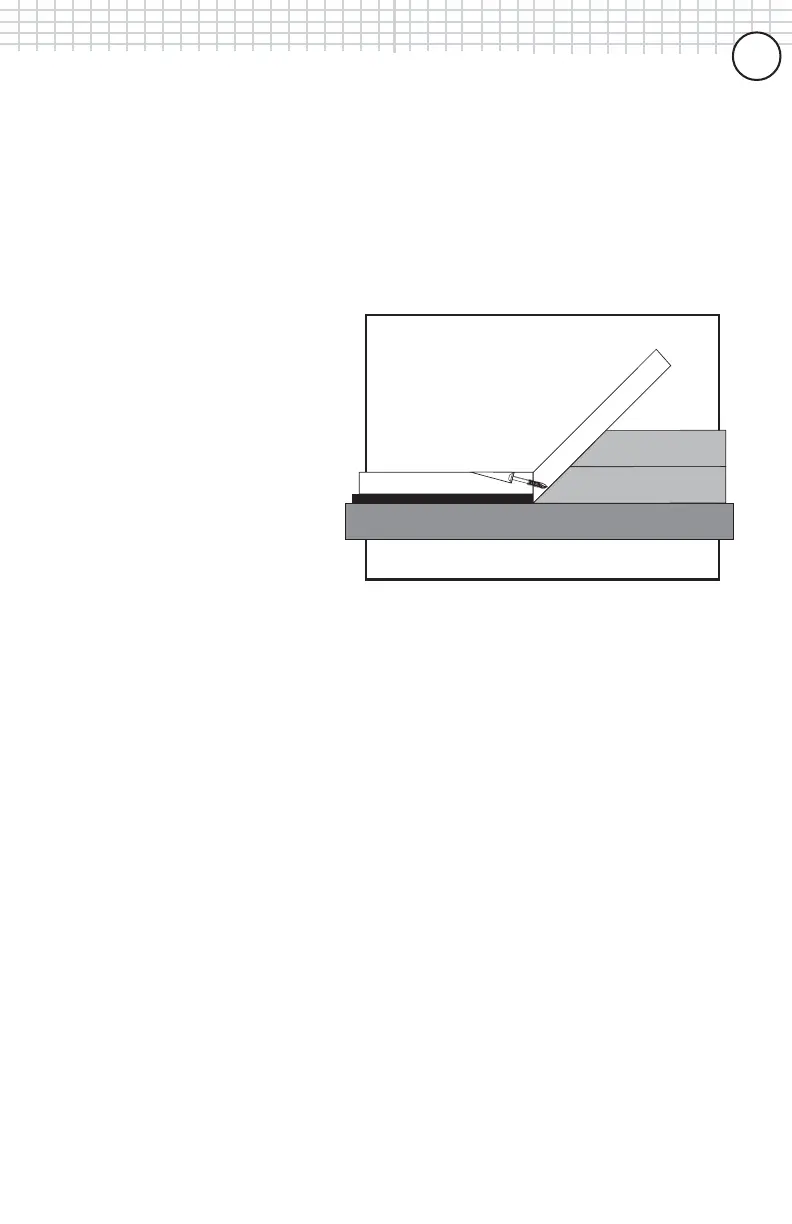

2. Build an assembly jig from scrap stock.

We recommend that you first

cut a plywood base 8” by

12”. Next laminate two 3/4”

x 4” x 12” hardwood pieces

together with glue and then

cut the block on an angle that

will complement your desired

assembly angle. Mount this

angled piece to the plywood.

Lastly, take your workpieces

to be assembled, align them

on their inside edges and

measure the overhang that

occurs. Make a shim the same height as the overhang measurement and attach

this to the plywood base so that the edge butts up with the angled piece.

3. Drill pocket holes into the edge of the 90 degree stile.

Prepare the pocket hole jig you will be using to center the screw in the material

thickness being joined and set your depth collar accordingly (see jig instructions).

We recommend that you place pocket holes every 6-8 inches along the length of

the stile. Test the drill depth and screw penetration in scrap workpieces that are

the same thickness as your actual stock before final assembly. If the screw tip

protrudes too far into the second workpiece you can simply set the depth collar

closer to the step of the drill bit to create a shallower hole.

4. Position stiles and drive screws.

Apply glue at this time if desired. Work from one end as you slide the stiles

across the assembly jig you have created. Press down onto the angled stile as

you assemble to create a uniform overhang.

5. Remove overhang from the front edge.

Remove the overhang from the front edge of the workpieces with a jointer,

sander or hand plane once assembled (if you don’t have a jointer, you can tip our

table saw blade to 45 degrees, cut it close and then finish with a belt sander).

3/4" x 4" x 12" before

ripping at 45 deg.

3/4" x 4" x 12" before

ripping at 45 deg.

3/4" x 8" x 12" plywood

SHIM

Loading...

Loading...