Caution

Caution

!

Controlmatic E.2

21

2.6 Unauthorized modification and manufacture of

spare parts

Modifications or alterations of the equipment supplied are

only permitted after consultation with the manufacturer.

Original spare parts and accessories authorized by the manu-

facturer ensure safety.

The use of other parts can invalidate any liability of the manu-

facturer for resulting damage.

2.7 Unauthorized modes of operation

The warranty relating to the operating reliability and safety of

the device s upplied is only valid if the device is used in accord-

ance with its designated use as described in section 4 of this

manual. The limits stated in the operating instructions must not

be exceeded under any circumstances.

3 Transport and temporary storage

3.1 Transport

To prevent damage during transport, the

automatic control unit must not be handled

or lifted by the power cable, and it must be protected against

any impacts or falls.

3.2 Temporary storage/Preservation

The device should be stored in a dry, dark, frost-proof room not

exposed to sunlight.

4 Description of the product and

accessories

4.1 Technical specification

The Controlmatic E.2 control unit is designed for controlling au-

tomatic pump starting and stopping.

The pump is started after a consumer installation has been

opened, as indicated by a flow and resulting pressure drop in

the piping system.

Controlmatic E.2 detects a fluid flowin the piping system.When

flow has stopped, the unitwillstop thepump afterapprox.5sec-

onds.

Apart from the automatic switchgear, the unit also comprises a

built-in membrane designed to provide a water reserve and

thus limit the switching frequency of the unit.

A swing check valve prevents the built-up pressure in the dis-

charge line from decreasing again.

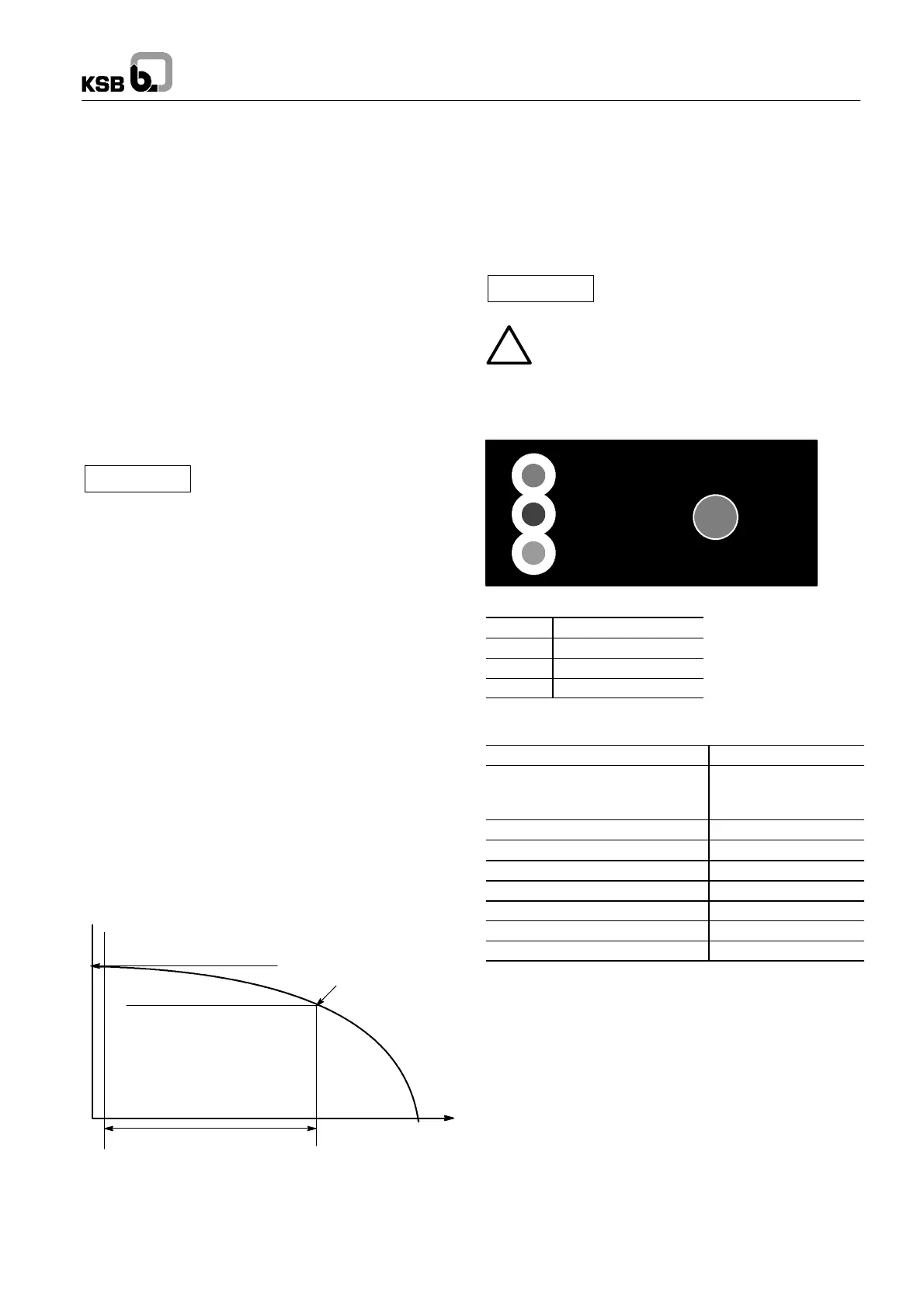

Consumer installation closes

(zero flow)

Pump operating range

Consumer installation opens

(start-up pressure)

Factory setting: 1.5 bar

Pp ≥ 2.2 bar (Pc+0.7 bar)

Pp = Pump pressure

Pc = Pressure setting of Controlmatic E.2 (1.5 bar)

Please note:

Controlmatic E.2 cannot be used for pressure boosting. Its

outlet pressure equals the pump’s discharge pressure.

Fluids handled:

D Clean water without solid particles

D Chlorinated swimming-pool water (max. 0.3 %)

D Water-soluble s ubstances

D Fertilizers

D Wood preservatives and pesticides

(Unit must be flushed through after every application).

The unit must not be used for the following fluids:

D corrosive fluids

D flammable fluids

D explosive fluids

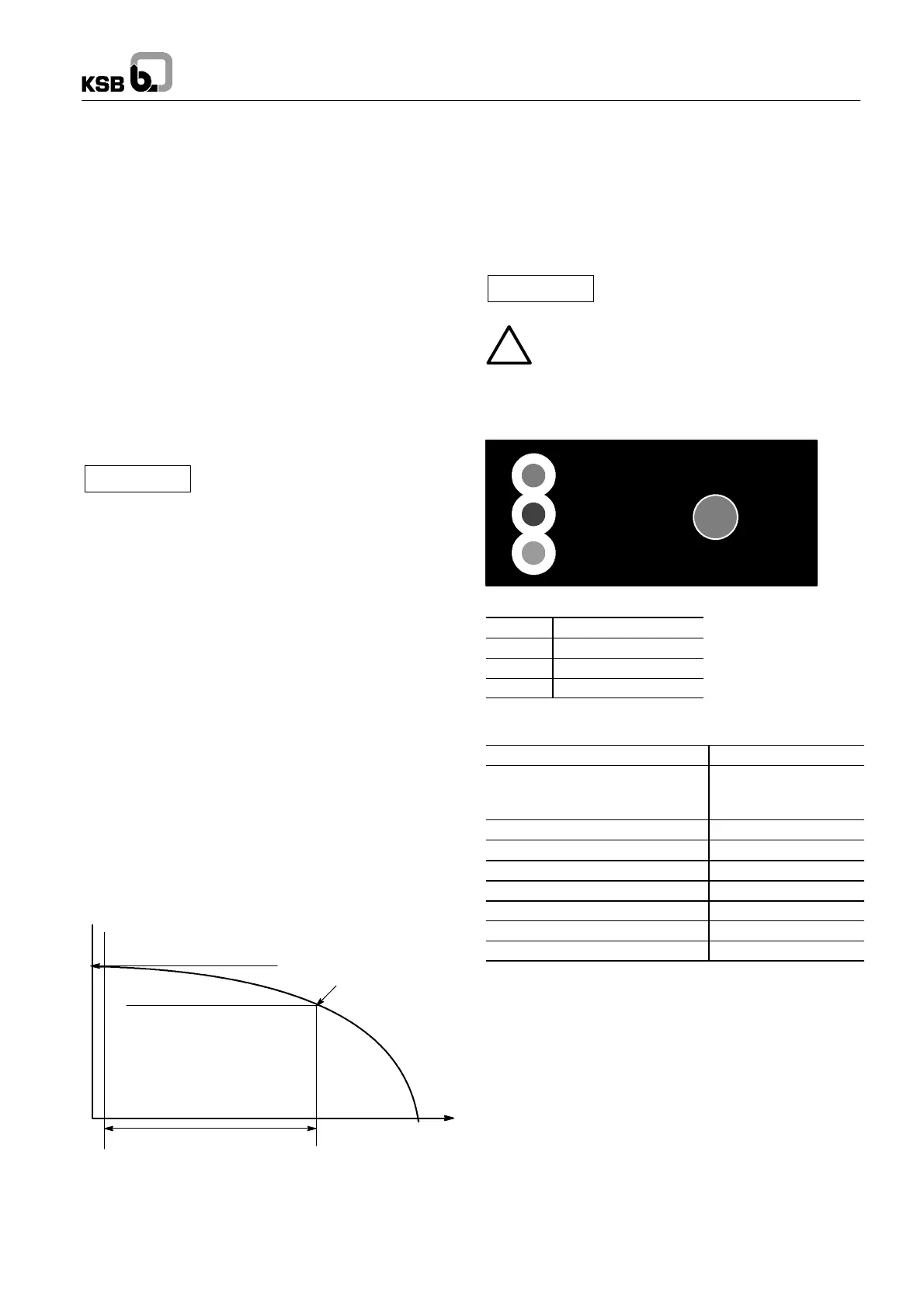

4.2 Indicator lamps

Reset

Power

On

Failure

Key:

Green

Power (Energized)

Red Failure (Fault)

Amber: On (Running)

Reset Initialization

4.3 Technical data

Max. operating pressure

10 bar

Max. amperage

(Check against pump operating

manual)

10 A

Pumped fluid temperature 0--60C

Max. flow rate 10 m

3

/h

Min. flow rate 0.09 m

3

/h

Voltage/Frequency 220--240 V, 50/60 Hz

Enclosure IP 65

Power supply cable 1.5 m

Minimum start-up pressure 1.5 bar

4.4 Designation

Type: Controlmatic E.2.

Ident. No.: 39 300 031

4.5 Design details

Controlmatic E.2 is made of high-grade plastic materials only.

KSB’s scope of supply includes:

D Power cable and standardized plug

D Standardized plug s ocket

D Integrated swing check valve

4.6 Accessories

D The automatic control unit is supplied ready to be plugged in.

Accessories can be ordered through your distributor.

Loading...

Loading...