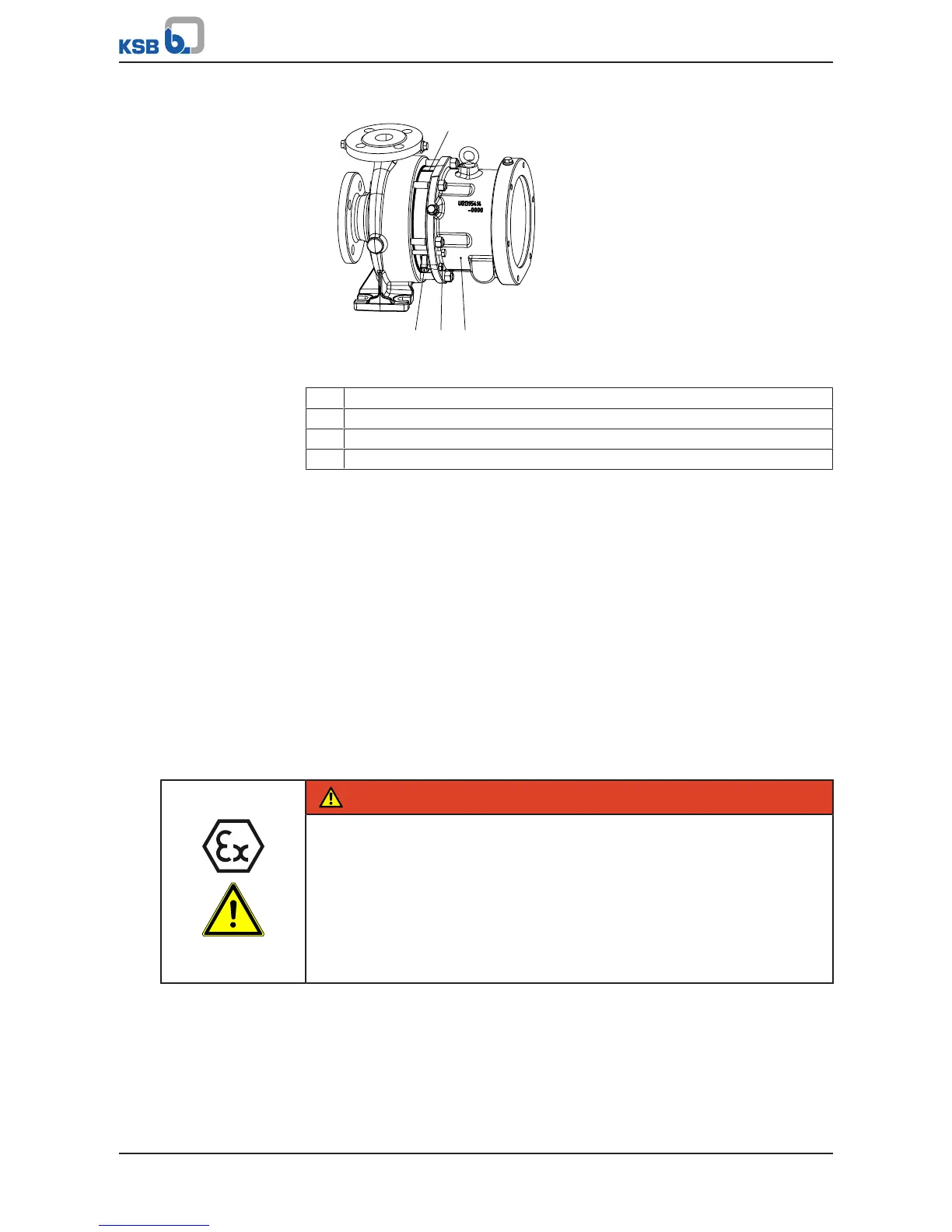

Fig.24: Fastening the bearing bracket lantern to the casing cover (design with

clamped casing cover)

1 Casing cover 161

2 Hexagon head bolt 901.31

3 Bearing bracket lantern 344

4 Marking on casing cover facing upwards

3. Place bearing bracket lantern 344 onto casing cover 161 (see illustration:

Fastening the bearing bracket lantern to the casing cover (design with clamped

casing cover)).

4. Mount bearing bracket lantern 344 on casing cover 161 with hexagon head bolts

901.31. Observe the tightening torques. (ðSection7.6,Page86)

5. Remove the guard.

6. Fit studs 902.04.

7.5.6 Fitting the rolling element bearings

ü The notes and steps stated in (ðSection7.5.1,Page70) to

(ðSection7.5.5,Page76) have been observed/carried out.

ü The individual parts have been placed in a clean and level assembly area.

ü All dismantled parts have been cleaned and checked for wear.

ü Any damaged or worn parts have been replaced by original spare parts.

ü The sealing surfaces have been cleaned.

DANGER

Excessive temperatures caused by increased friction at the joint rings

Explosion hazard!

Fire hazard!

Damage to the pump set!

Risk of burns!

▷ Never apply paint to joint rings 411.77 and 411.78.

▷ Ensure that the joint rings have contact in the axial direction and are slightly

pre-loaded.

1. Insert circlip 932.02 into the groove of the bearing's outer ring (rolling element

bearing 321.02).

2. Press rolling element bearing 321.02 onto shaft 210.01 until it rests against the

shaft shoulder (do not heat up the rolling element bearing) and secure it with

circlip 932.80. Circlip 932.02 is fitted on the side pointing towards the drive end.

On oil-lubricated models, the shield of rolling element bearing 321.01 is fitted on

the side pointing towards the pump end.

Loading...

Loading...