7 Servicing/Maintenance

79 of 108

Magnochem

3. Slide shaft 210.01 with rolling element bearing 321.02 into bearing bracket 330

from the drive end.

4. Fit bearing cover 360.02.

Oil-lubricated models only: fit bearing cover 360.02 with gasket 400.02.

5. Tighten hexagon socket head cap screws 914.02 to the torques given in this

manual. (ðSection7.6,Page86)

6. Fit joint ring 411.78.

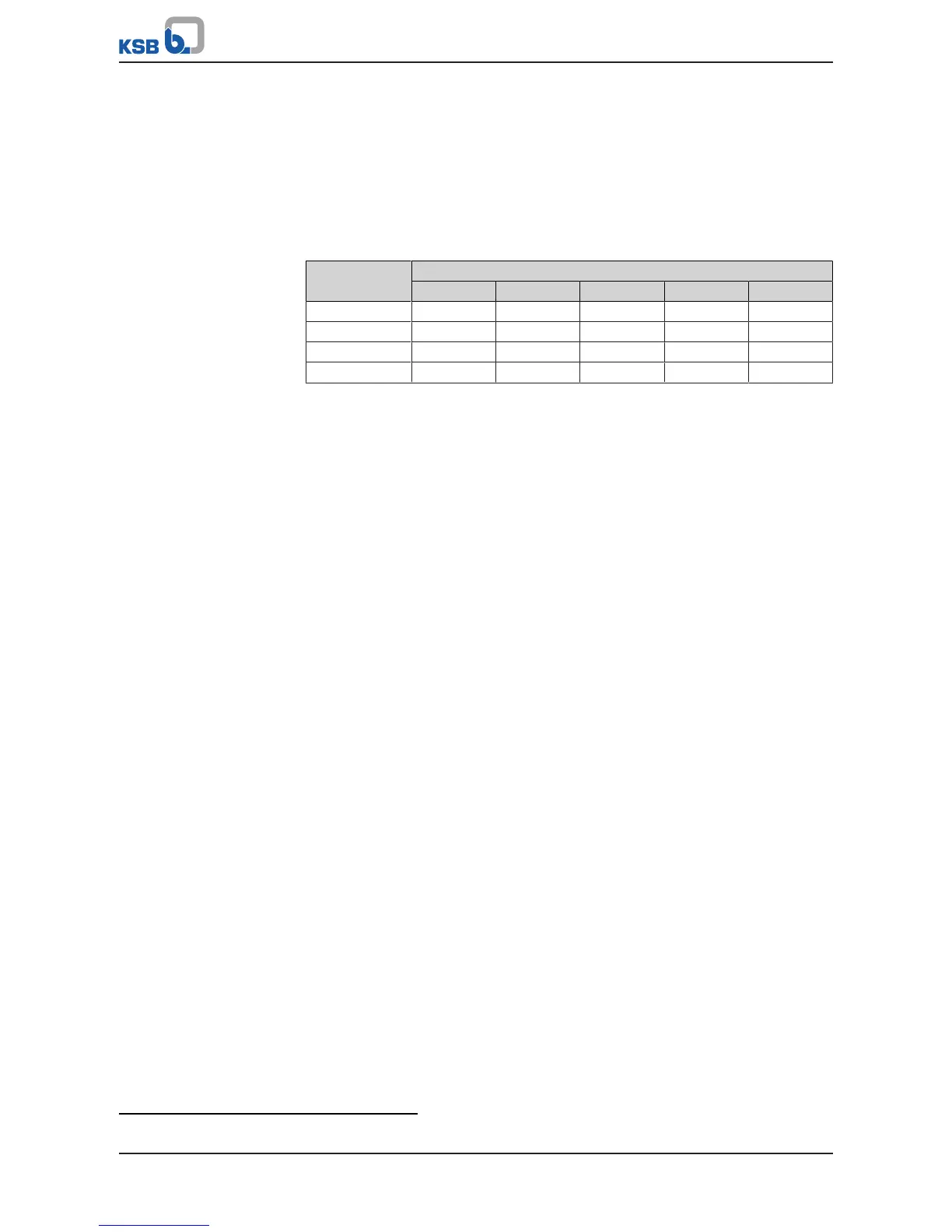

Table23: Number of springs 950.24

Bearing bracket Nominal diameter of magnetic coupling

85 123 172 235 265

CS40 1 1 - - -

CS50 1 1 1 2 -

CS60 1 1 1 2 -

CS80 - - 2

13)

2

13)

2

13)

7. Insert wave spring 950.24 into bearing bracket 330 (see table: Number of springs

950.24). For this purpose, the bearing bracket should preferably be placed in a

vertical position.

For models with leakage barrier and nominal pump pressure PN40 only: insert

disc spring 950.24 into bearing bracket 330. The highest point of the disc spring

points towards the pump end. For this purpose, the bearing bracket should

preferably be placed in a vertical position.

8. Press rolling element bearing 320.01 or 321.01 onto shaft 210.01 until it rests

against the shaft shoulder (do not heat up the rolling element bearing). When

pressing it in, only apply pressure to the inner ring of rolling element bearing

320.01 or 321.01. On oil-lubricated models without leakage barrier and oil-

lubricated models with shaft seal ring, the shield of rolling element bearing

321.01 is fitted on the side pointing towards the pump end.

9. Oil-lubricated models only (without leakage barrier): carefully slide O-ring 412.28

onto shaft 210.01 over the shaft shoulder and fit it in the groove.

10.Oil-lubricated models (without leakage barrier) only: fit bearing cover 360.01

with gasket 400.01.

11.Oil-lubricated models (without leakage barrier) only: tighten hexagon socket

head cap screws 914.01 to the torques given in this manual.

(ðSection7.6,Page86)

12.Make sure that the shaft can easily be rotated by hand.

7.5.7 Fitting the shaft seal – design with leakage barrier (optional)

7.5.7.1 Reassembling the shaft seal – design with shaft seal ring

ü The notes and steps stated in (ðSection7.5.1,Page70) to

(ðSection7.5.6,Page78) have been observed/carried out.

ü The bearing bracket is kept in a clean and level assembly area.

ü The individual parts are kept in a clean and level assembly area.

ü The sealing surfaces have been cleaned.

ü Any damaged or worn parts have been replaced by original spare parts.

13) For leakage barrier models with nominal pump pressure PN40: 1

Loading...

Loading...