REGULAR CHECKS AND MAINTENANCE WORK76

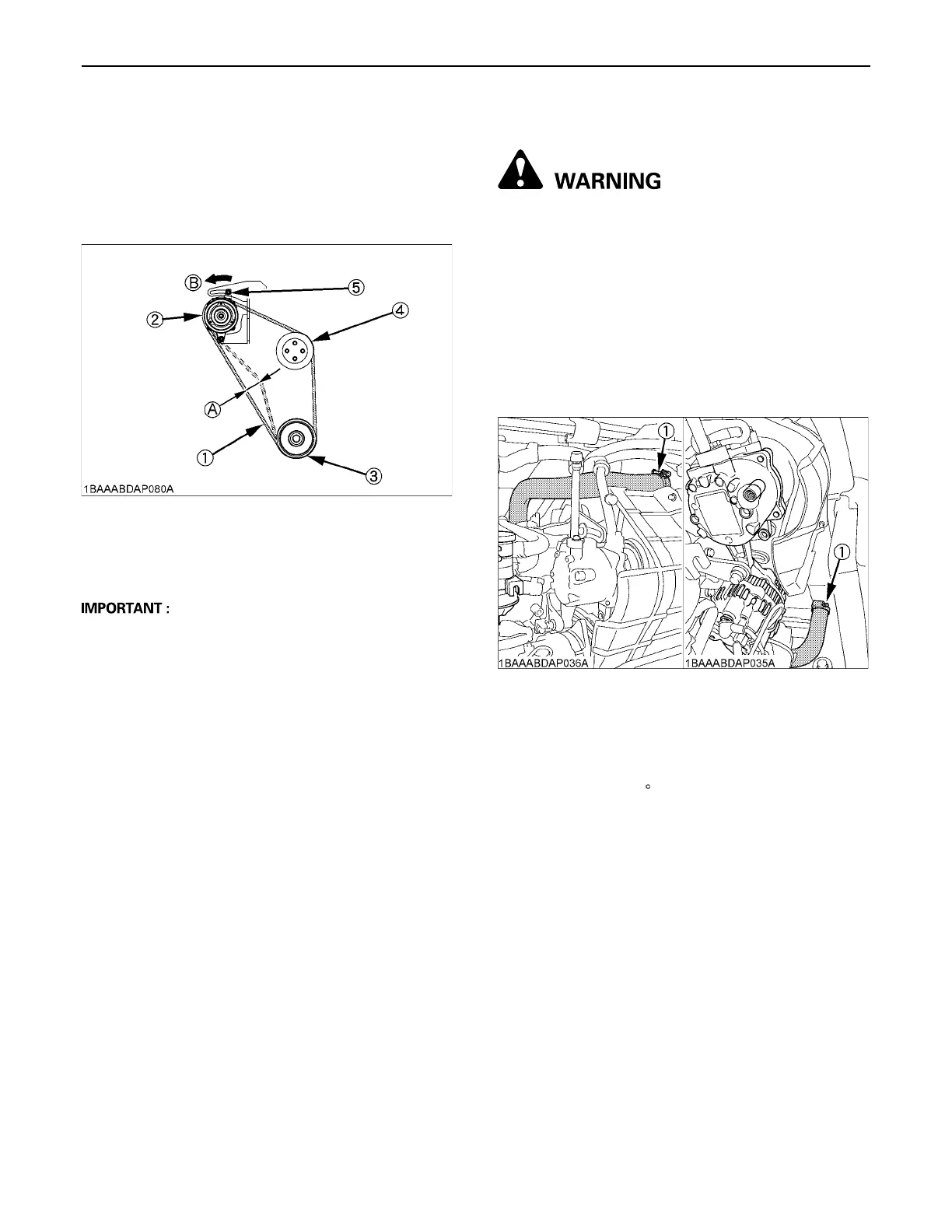

C Checking and adjustment of the fan belt tension

1. Press the fan belt down in the middle, with a force of

approx. 7 kgf (15.4 lbs). The belt tension is correct if it

deflects about 12 to 15 mm (0.47 to 0.59 in.). If

otherwise, loosen bolt and shift the AC compressor in

the direction shown by the arrow.

2. Replace the fan belt if worn out, cracked or torn.

A If the engine is run with a loose fan belt, the belt could

slip and cause insufficient room temperature control.

Check fan belt tension regularly.

3. After adjusting the V-belt, attach the V-belt cover with

the three bolts.

Tightening torque must be between 3 to 5 N-m (2.2 to

3.7 ft-lbs).

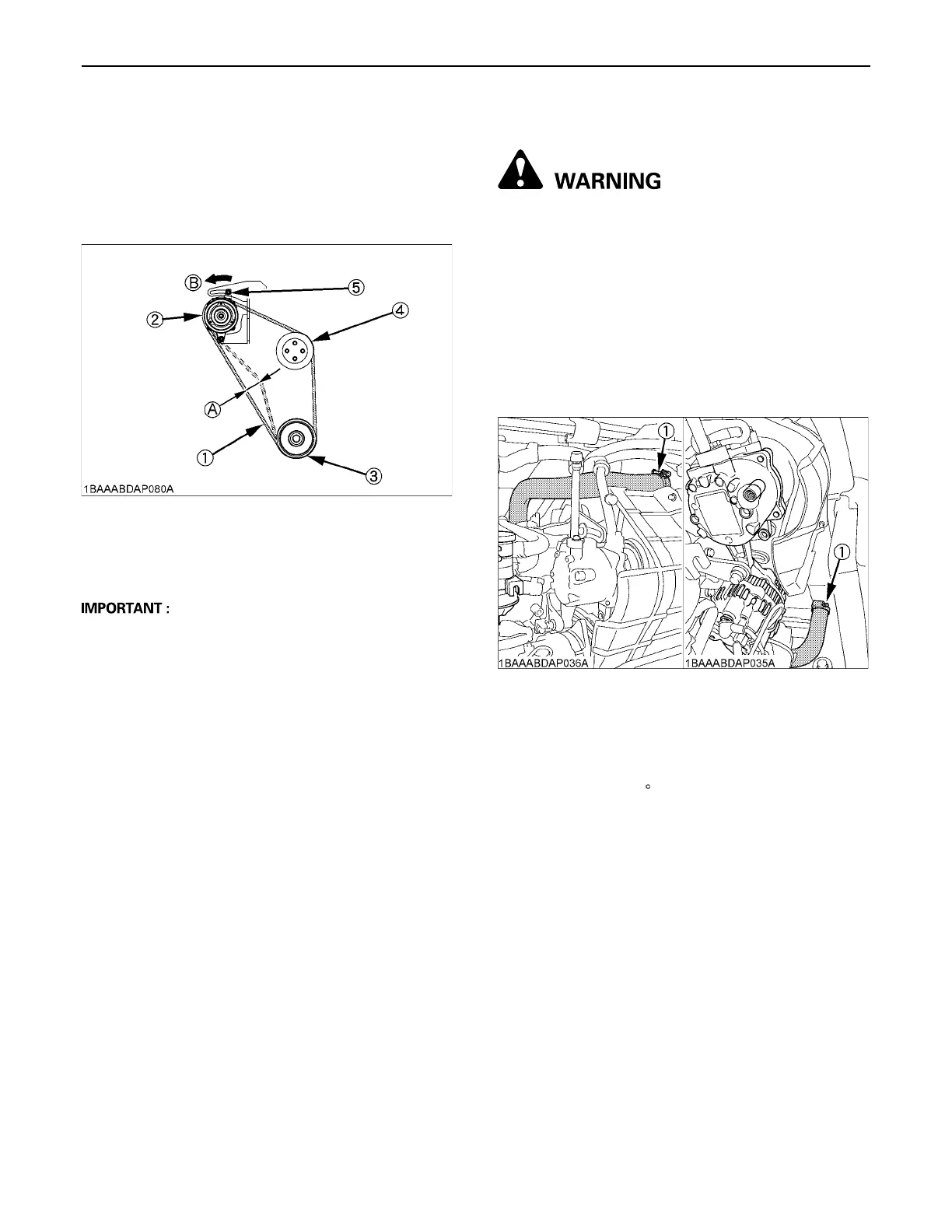

BChecking Radiator Hoses and Clamps

To avoid personal injury or death:

A Wait long enough for the radiator coolant to

cool down.

Check the coolant hoses for proper connection. This

check should be carried out every 200 hours or every 6

months, whichever comes first.

1. Should the hose clamps become loose or coolant

leaks, tighten the hose clamps properly.

2. Should the radiator hoses become swollen, aged or

cracked, they must be replaced and the hose clamps

tightened again properly.

BGrease Swing Ball Bearing

1. Grease through the respective grease fitting. (at the

central fitting)

2. Grease at each 90 (1.58 rad.) position of the swing

frame.

Using the grease gun,apply 5 shots at every position.

(1) Fan belt

(2) AC compressor

(3) Pulley

(4) Fan pulley

(5) Bolt and nut

(A) 12 to 15 mm (0.47 to 0.59 in.)

(B) Tighten

(1) Radiator hoses and clamps (Both sides)

Loading...

Loading...