SECTION III

Adjustments

P 3.7

L. CAM ASSEMBLY:

The cam assembly drives the pick through its cycle

and raises the closure stop at the proper time to

stop the closure strip so the leading closure can be

separated from the remaining strip. The closer cam

fastens to the outside edge of the cam hub. The

switch cam contacts the cam switch stopping the

motor and cam assembly when the pick is in the

parked or neutral position (Figure 3.13). The cam

assembly should remain on the motor shaft with no

need for adjustment. If however the cam assembly

is disassembled the following information is helpful

to reassemble it.

The cam is adjusted to drive either an 086A Model

100 or 086A Models 200, 300, and 400. Correct

assembly of the components provide the required

pick stroke so the closer functions properly. Align

the cam to the hub as follows:

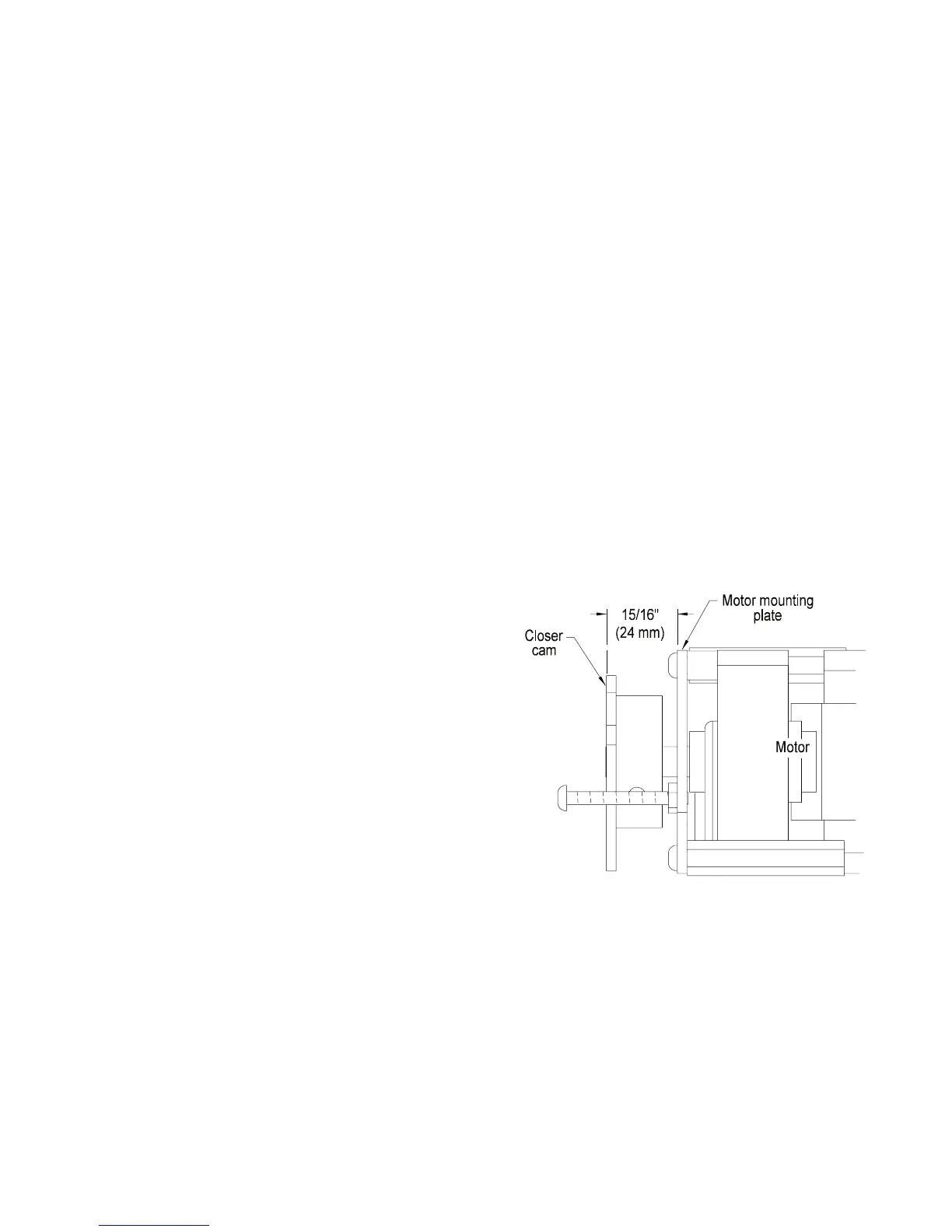

1. Hold the cam so the stamped letter “R” is on the

correct side for your model closer as shown in

the appropriate view in Figure 3.11

2. Position the hub behind the cam. Rotate the

hub until one of the two 8-32 tapped holes in the

hub aligns with the countersunk hole in the cam.

3. Insert the flat head screw to secure the two

parts.

4. If the switch cam has been removed, remount it

after the cam and hub have been connected.

Square up the switch cam to the main cam hub

and then tighten into place (Figure 3.12).

5. Install the cam assembly onto the motor shaft.

Refer to part L below.

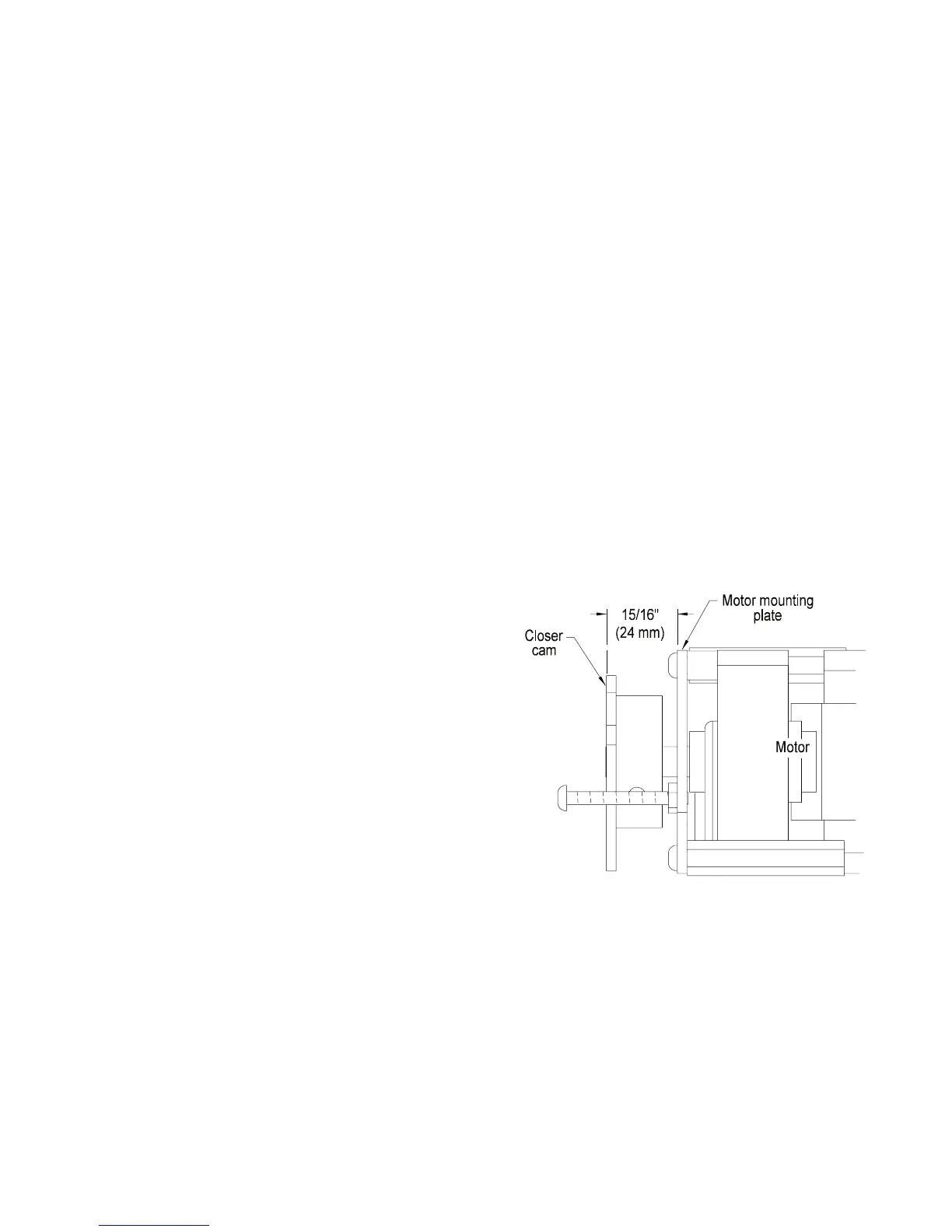

M. CAM ASSEMBLY LATERAL ALIGNMENT:

1. Set the lateral (side to side) position of the cam

assembly so the outside edge of the closer cam

measures 15/16” (24mm) from the outside edge

of the motor plate (Figure 3.12).

2. Rotate the cam assembly to position the set

screw over the flat on the motor shaft and

tighten the set screw. The angular position of

the cam assembly is not important because the

motor will stop with the cam in the correct

position when the switch cam contacts the limit

switch.

3. Tighten the set screw.

086A 08 08

Figure 3.12

Loading...

Loading...