2NM/2NX/2NY/2NZ/2P0/2P6

1-4-80

(6) Black streaks appear longitudinally.

Print example Cause of trouble

1. Dirty charging roller

2. Flawed or dirty drum unit

3. Damaged or paper dust bitten cleaning blade

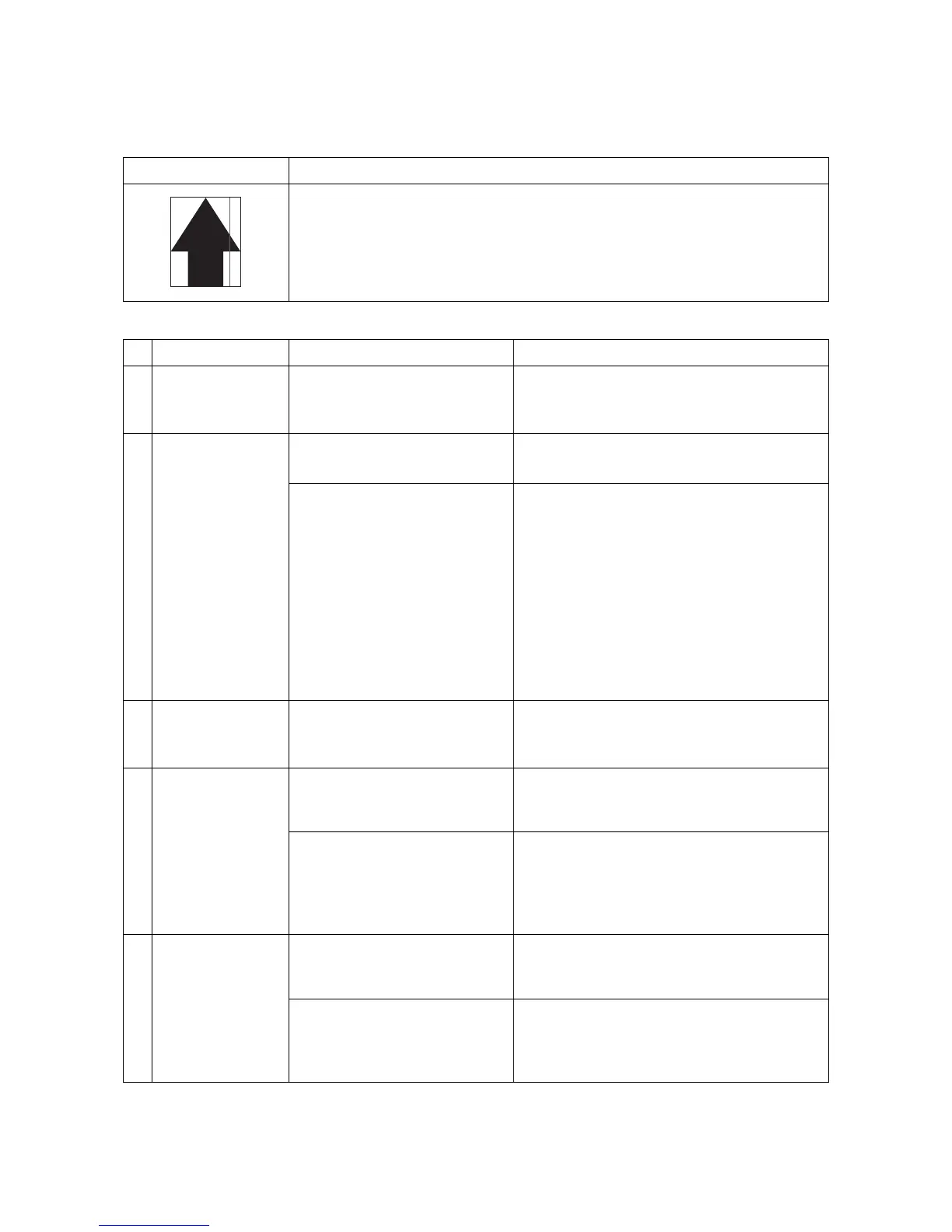

Defective part Check description Corrective Action

1

Separation brush Check if the separation brush is

dirty with paper dusts and waste

toner.

If the separation brush is dirty, clean it using a

brush.

2

Drum unit Check if drum is dirty on its sur-

face.

Execute drum refreshing.

(System Menu >Adjustment / Maintenance)

1. Check if the drum has

scratches.

2. Check whether the edge of

the cleaning blade is dam-

aged.

3. Check whether it is abraded

or paper dusts are accumu-

lated.

4. Check whether toner is

accumulated in the cleaning

section.

Replace the drum unit.

(see page 1-5-36)

3

Charging roller unit Check if there is no toner streaks

on the surface of the charging

roller.

If the charging roller has streaks on its surface,

clean the charging roller. Replace the charging

roller, if necessary.

4

Transfer roller unit

1. Check if the transfer roller is

contaminated on its surface

or damaged.

If smears and scuff are observed on the trans-

fer roller unit, replace the unit.

(see page 1-5-38)

2. Check the connecting termi-

nals of high voltage are not

dirty or deformed.

If the connector or terminals are dirty, clean.

If the connecting terminals are deformed, cor-

rect for a proper conduction.

Replace the high voltage PWB.

(see page 2-2-20)

5

Fuser unit

1. Check if the paper separa-

tion puddle is contaminated

with toner.

If the paper separation puddle is dirty, clean the

paper separation puddle.

2. Check the device is adjusted

for a correct paper weight

that matches the paper in

use.

If the settings for paper weight and the paper

being used do not match, make a proper con-

figuration.

Loading...

Loading...