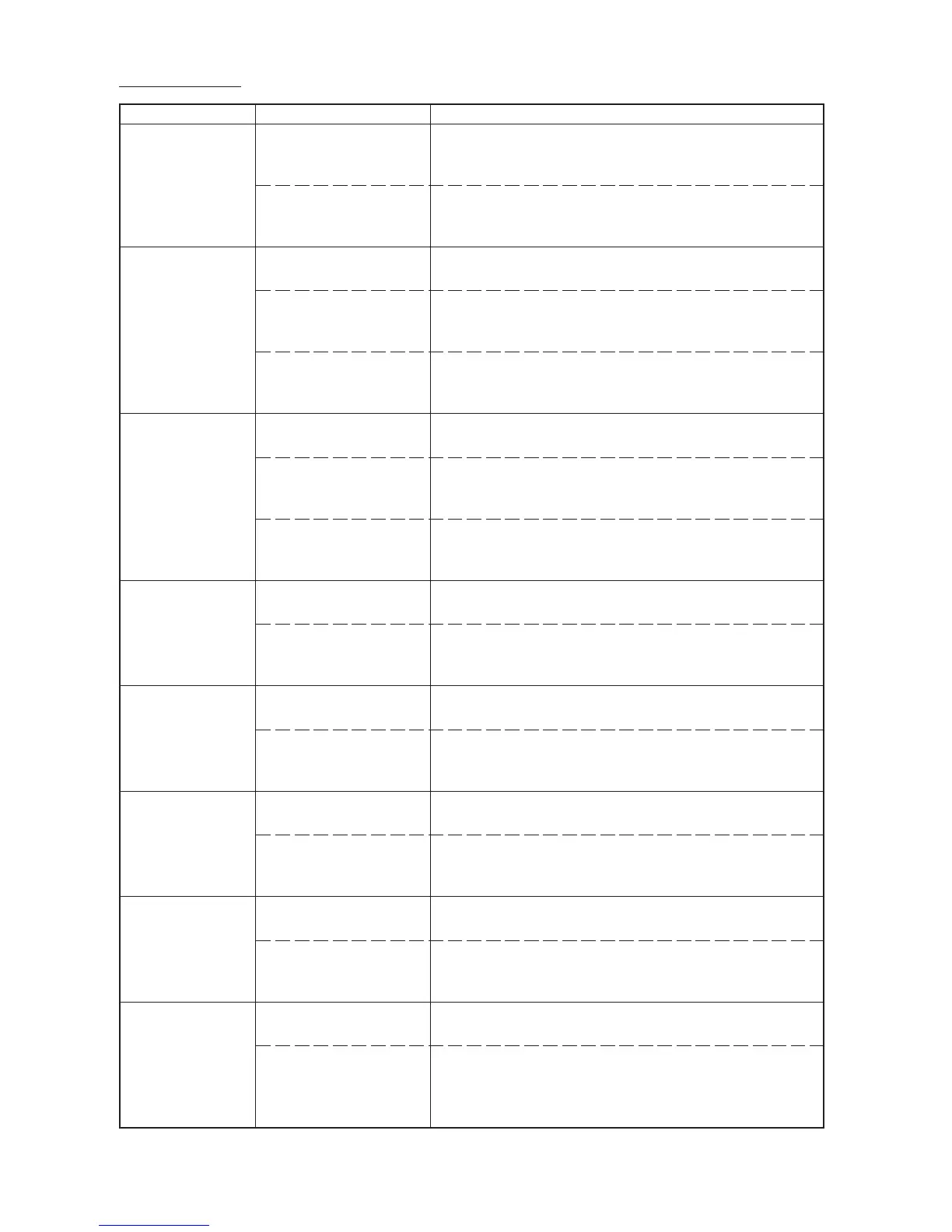

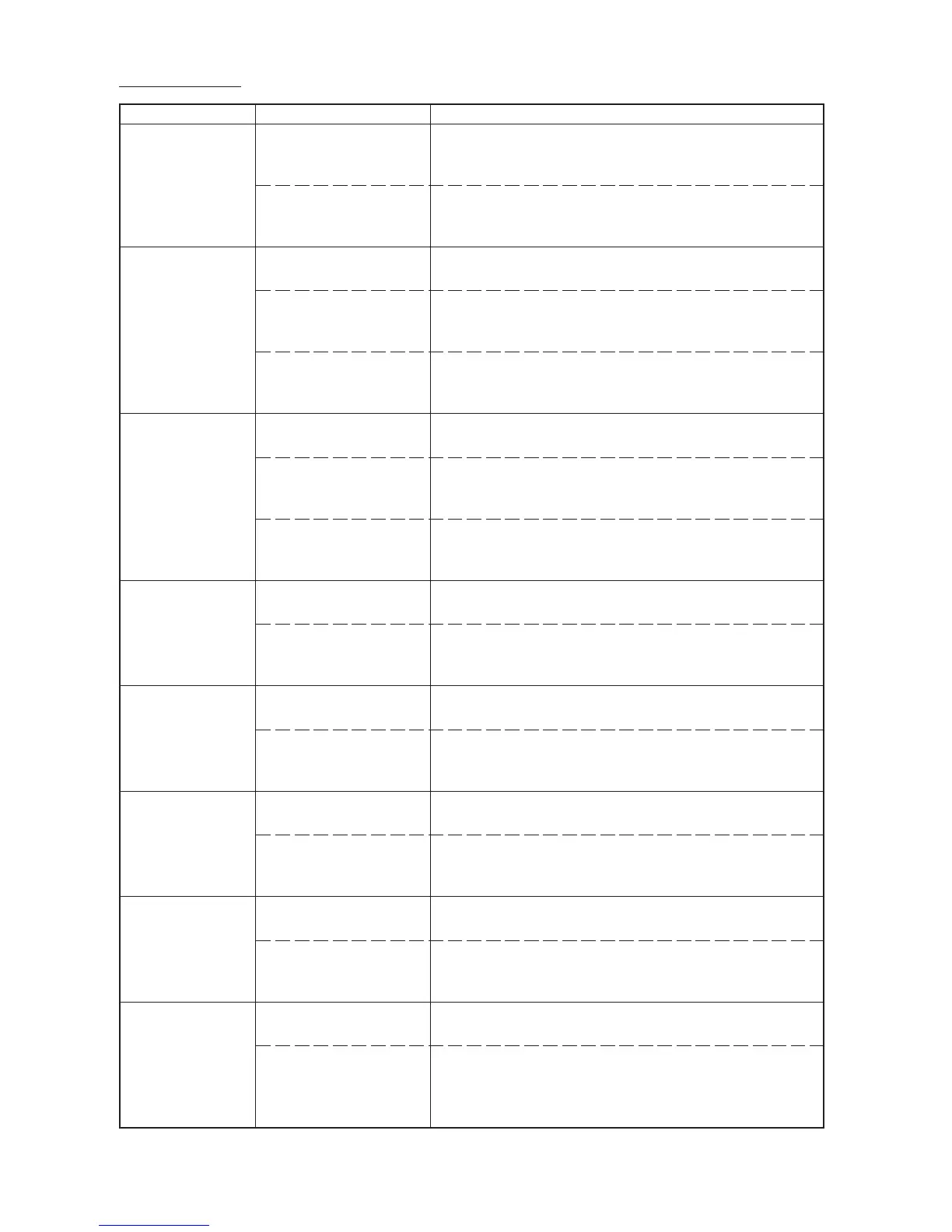

FS-9120DN/9520DN

1-5-36

Problem Causes Check procedures/corrective measures

(4)

The eject motor

does not operate.

(5)

The upper lift motor

does not operate

(C1010).

(6)

The lower lift motor

does not operate

(C1020).

(7)

Cooling fan motor 1

does not operate.

(8)

Cooling fan motor 2

does not operate.

(9)

Cooling fan motor 3

does not operate.

(10)

Cooling fan motor 4

does not operate.

(11)

Cooling fan motor 5

does not operate.

Defective eject switch.

Defective engine controller

PWB.

Broken upper lift motor

coil.

Poor contact in the upper

lift motor connector termi-

nals.

Defective engine controller

PWB.

Broken lower lift motor

coil.

Poor contact in the lower

lift motor connector termi-

nals.

Defective engine controller

PWB.

Broken cooling fan motor 1

coil.

Poor contact in the cooling

fan motor 1 connector ter-

minals.

Broken cooling fan motor 2

coil.

Poor contact in the cooling

fan motor 2 connector ter-

minals.

Broken cooling fan motor 3

coil.

Poor contact in the cooling

fan motor 3 connector ter-

minals.

Broken cooling fan motor 4

coil.

Poor contact in the cooling

fan motor 4 connector ter-

minals.

Broken cooling fan motor 5

coil.

Poor contact in the cooling

fan motor 5 connector ter-

minals.

Run maintenance item U031 and turn the eject switch on and off

manually. If "1" is not displayed when the switch is on or "0" is

not displayed when the switch is off, replace eject switch.

Run maintenance item U030 and check if YC16-B11, YC16-B12,

YC16-B13 and YC16-B14 on the engine controller PWB go low.

If not, replace the engine controller PWB.

Check for continuity across the coil. If none, replace the upper

lift motor.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

Check if 24 V DC is output across YC13-A17 on the engine con-

troller PWB right after the upper cassette is installed. If not, re-

place the engine controller PWB.

Check for continuity across the coil. If none, replace the lower lift

motor.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

Check if 24 V DC is output across YC13-B7 on the engine con-

troller PWB right after the lower cassette is installed. If not, re-

place the engine controller PWB.

Check for continuity across the coil. If none, replace cooling fan

motor 1.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, repair or replace the cable.

Check for continuity across the coil. If none, replace cooling fan

motor 2.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, repair or replace the cable.

Check for continuity across the coil. If none, replace cooling fan

motor 3.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, repair or replace the cable.

Check for continuity across the coil. If none, replace cooling fan

motor 4.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, repair or replace the cable.

Check for continuity across the coil. If none, replace cooling fan

motor 5.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, repair or replace the cable.

Loading...

Loading...