7

3000

English

WASHING OF THE NEW EQUIPMENT

• The equipment has already been adjusted at our factory with

light mineral oil left inside the pumping group as protection.

Therefore, wash with diluent before sucking the product.

• Lift the suction pipe and dip it into the solvent tank.

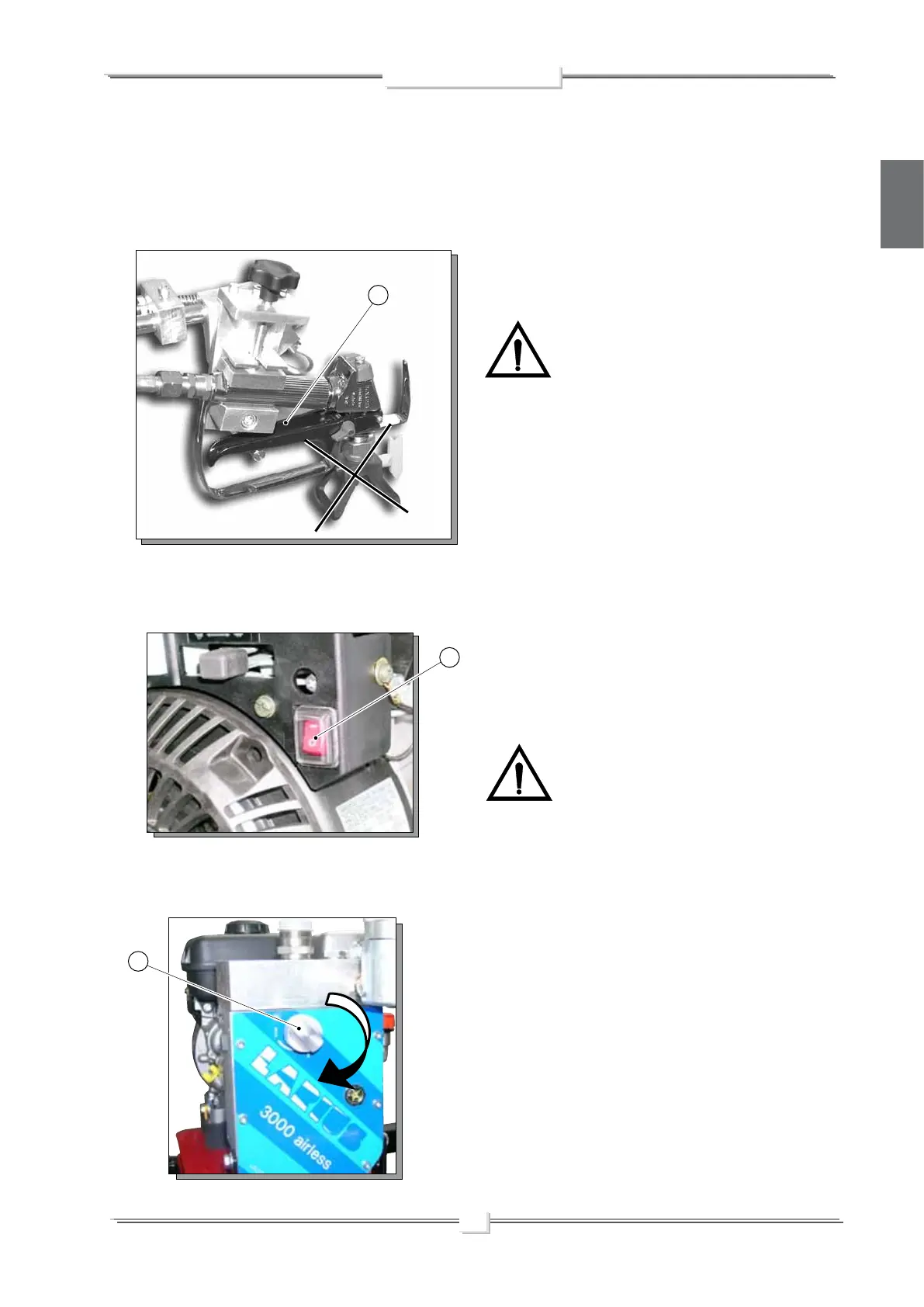

• Ensure the gun is without nozzle (G1).

• Turn the starting knob (G2) to "ON" position.

• Start the internal combustion engine as indicated in the “H

– OPERATION” chapter.

• Turn clockwise the pressure control knob (G3) so as the

machine works at idle speed.

• Point the gun at a container keeping and keep pressed the

trigger lever( so as to drain the oil inside) till a clean solvent

comes out. Now, release the lever.

• Remove the suction pipe and take away the solvent tank.

• Point the gun at the solvent tank and press the lever so as

to recover the residual solvent.

Absolutely avoid to spray solvents indoors.

• Now the machine is ready. Should you use water paints,

besides the solvent wash, a wash with soapy and then clean

water is suggested.

• Insert the gun trigger lock and assemble the nozzle.

PREPARATION OF THE PAINT

• Make sure the product is suitable to be used with a spray

gun.

• Mix and filter the product before using it. For filtration use

CLOSE-MESH and LARGE-MESH LARIUS METEX brai-

ds.

Make sure the product to be used is compatible

with the materials employed for manufacturing

the equipment (stainless steel and aluminium).

Because of that, please contact the supplier of

the product.

Never use products containing halogen hydrocarbons (as methy-

lene chloride). If these products come into contact with aluminium

parts of the equipment, can provoke dangerous chemical reactions

with risk of explosion.

G1

G3

G2

Loading...

Loading...