4. Use the buttons at the bottom to change the number of segments or

to display the temperature curve programmed so far:

[Delete] - Removes the currently selected segment (segment

number with a light background) from the program

sequence.

[Undo

delete]

- Reverses the last delete operation.

[Copy] - Inserts a copy of the currently selected segment into

the next line.

[Graph] - Displays the temperature-time diagram of the pro-

gram sequence created so far (all segments).

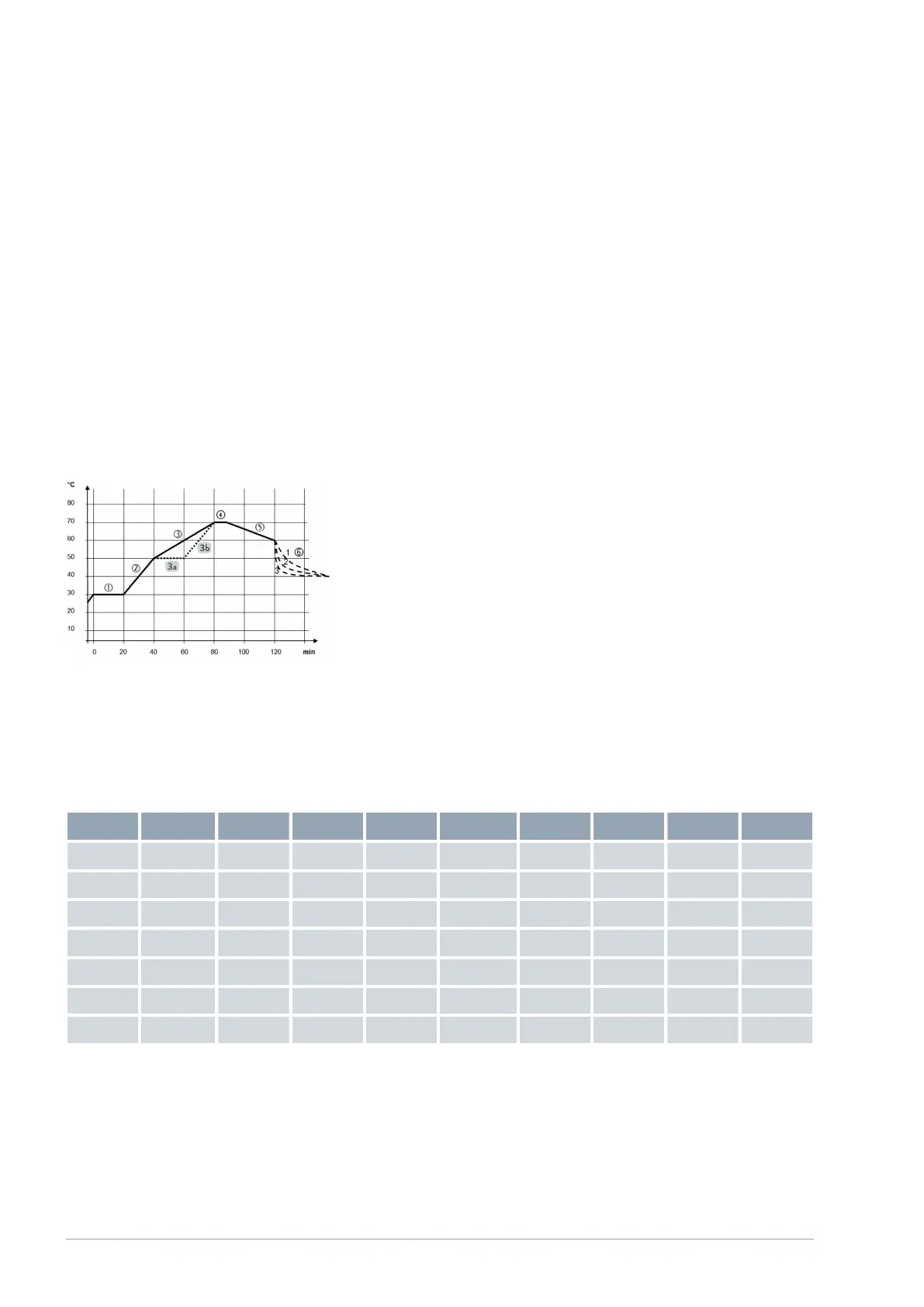

This aim of this example is to show you how it is possible to influence the

temperature profile of a program by changing individual segment settings.

The graphic opposite shows the original profile with a solid line, and the

edited profile with a dotted line. The cooling duration (segment 6) varies

depending on the type of device, application and other factors; it is shown by

dashed lines.

The original profile (solid line) roughly shows three sequence phases; the

values defined for them can be seen in the table below:

Segment 1: The start temperature 30 °C is maintained for 20 min.

Segment 2 – 4: The temperature is increased in 2 phases to 70 °C within

an hour, and then maintained for 10 min.

Segment 5 – 6: The temperature is increased to 60 °C within half an

hour and should then reduce to, and be maintained at, 40 °C without a

time limit, i.e. as quickly as possible.

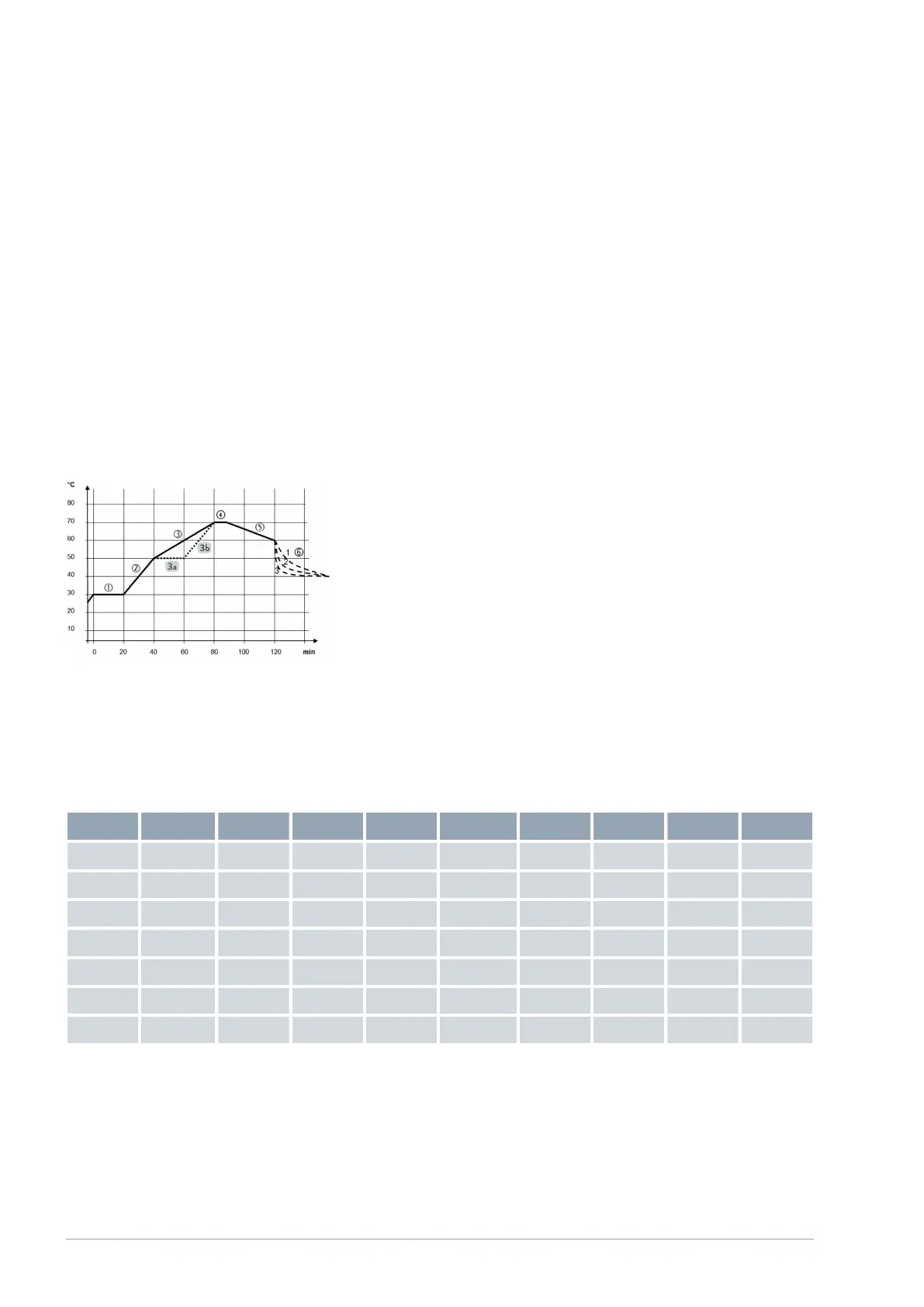

Table 1: Example of a program with segments

Seg. Seg. type Tend°C Time h:m

DT°C

Pump Control Out1 Out2 Out3

Start Start 30.00 ---- ----- 1 internal ----- ----- -----

1 Maintain 30.00 0:20 ----- 1 internal ----- ----- -----

2 Ramp 50.00 0:20 ----- 6 internal ----- ----- -----

3 Ramp 70.00 0:40 ----- 6 internal ----- ----- -----

4 Maintain 70.00 0:10 ----- 1 internal ----- ----- -----

5 Ramp 60.00 0:30 ----- 4 internal ----- ----- -----

6 Jump 40.00 0:00 ----- 4 internal ----- ----- -----

Example of a program with changes

Fig. 24: Example of a program with tem-

perature profiles

V1Command Touch operating unit30 / 51

Loading...

Loading...