Portable Plasma Torch Height Controller Manual (F1620)

35

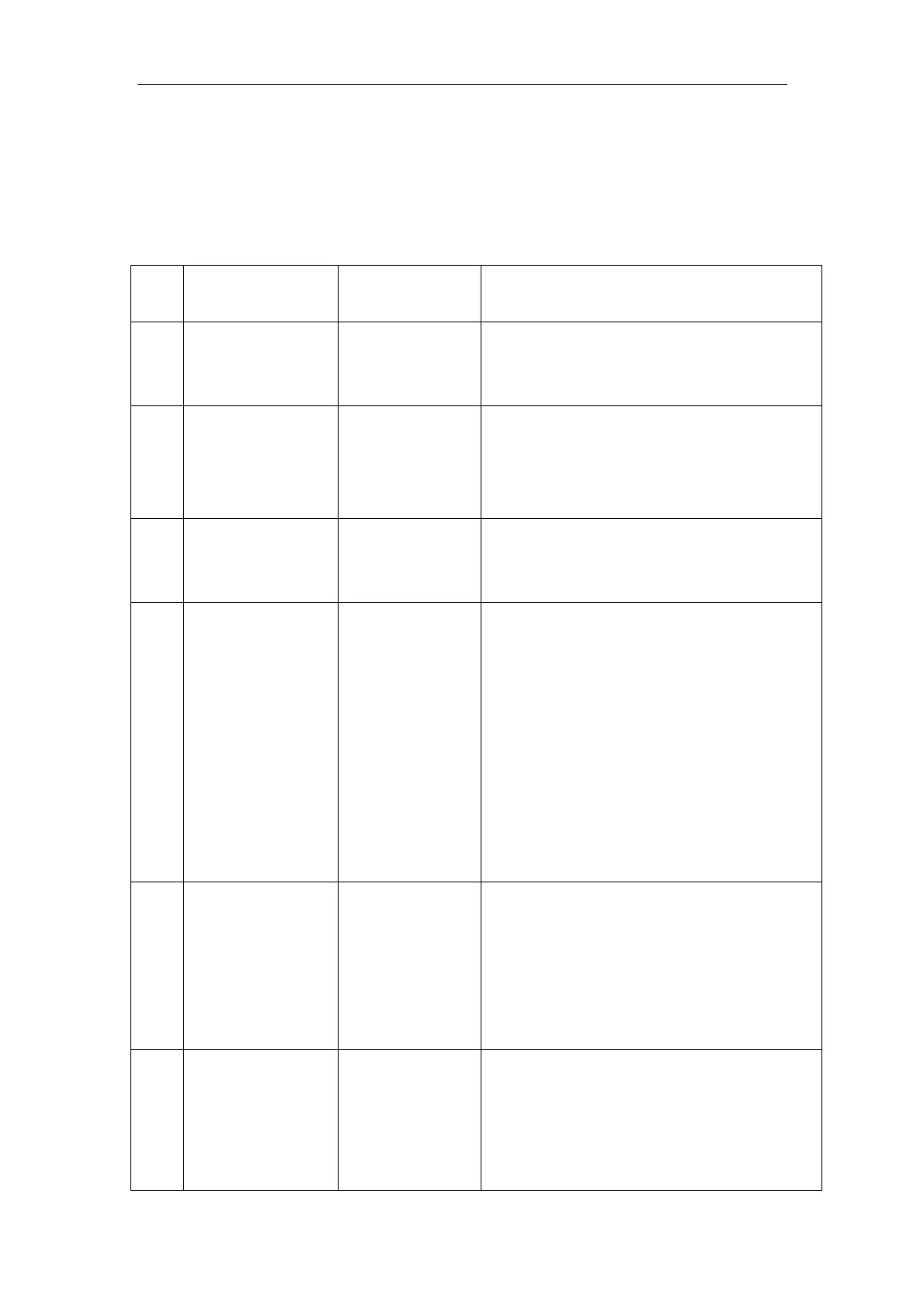

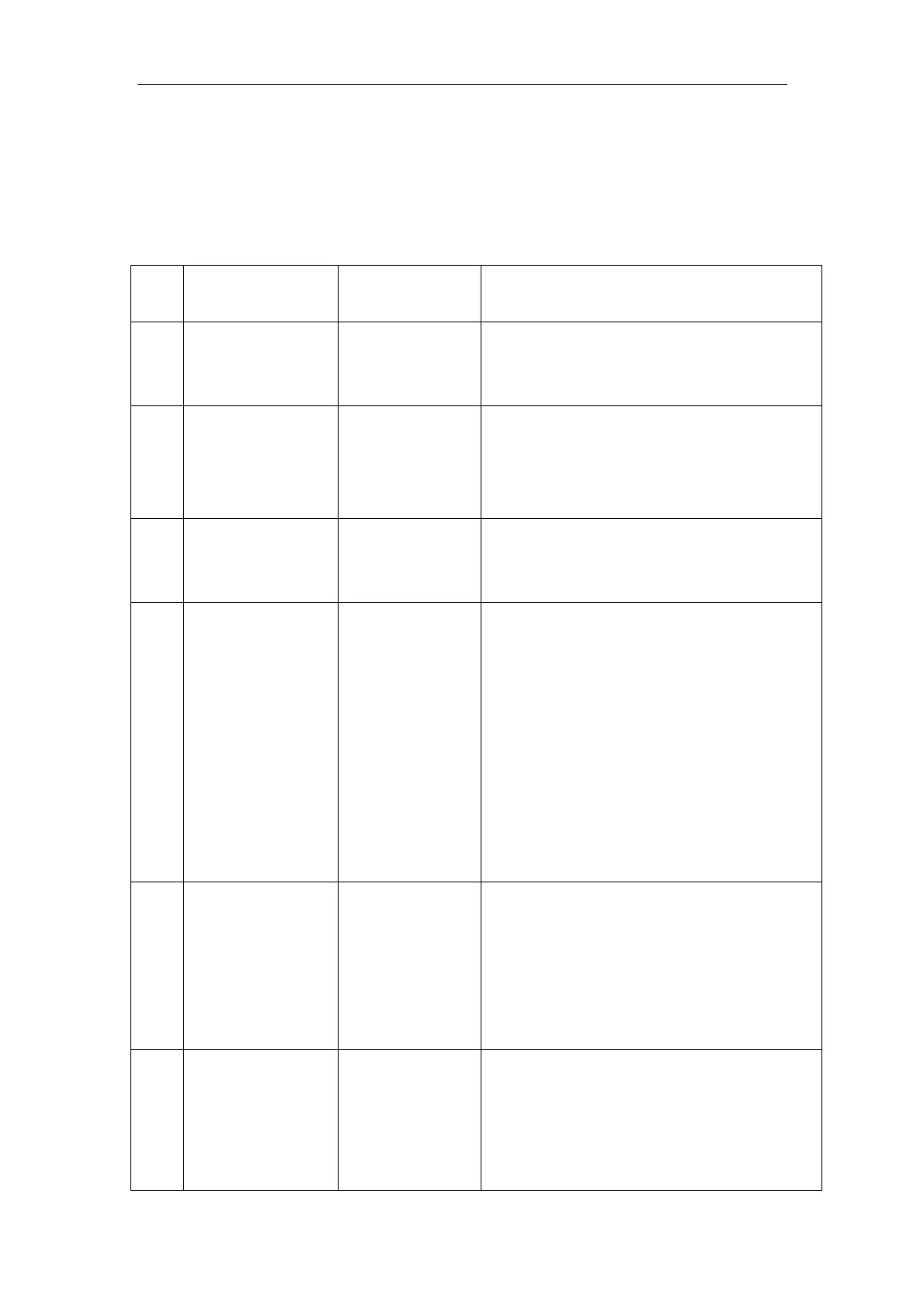

Chapter4commonproblems

During THC work, user can encounter some problem and solution as follows:

num

ber

Fault phenomenon Reason Solution

1 Nixie tube do not

display

Power source

module have

problem

Check whether the power source connection is

steady.

2 Motor do not turn Blocking signal

make it lock

1. Check whether UP_LIMIT/DOWN_LIMIT

signal make it lock

2. Over-current protection make motor driver

chip lock.

3 After motor turn, it

do not work

Motor chip is

protected by

over-current action

1. Check whether mechanical structure is stuck

4 After THC power

on, the motor has

been rising

Collision signal

can make motor

rise all the time

1. Check whether proximity switch wiring is

connected well, check whether parameter P13、

L09 or L08 is set well. If wiring is connected

true and parameter is set true, the red indictor is

lighted when proximity switch close

2. Check whether proximity switch is damaged

3. Check whether torch retaining cap

positioning wiring is connected well. In genal,

there do not have collision signal when torch

retaining cap do not contact with steel.

5 Arc voltage control

is unstable

1. Check whether the grounding is true.

2. Check whether plasma power source

cooling water is oozed.

3. Sensitivity coefficient P07 setting is too

large

6 Before IHS have

accomplished,

plasma can make arc

start work right

away

It always happen

in the case of arc

start signal control

Extend CNC positioning waiting time

Loading...

Loading...