Portable Plasma Torch Height Controller Manual (F1620)

36

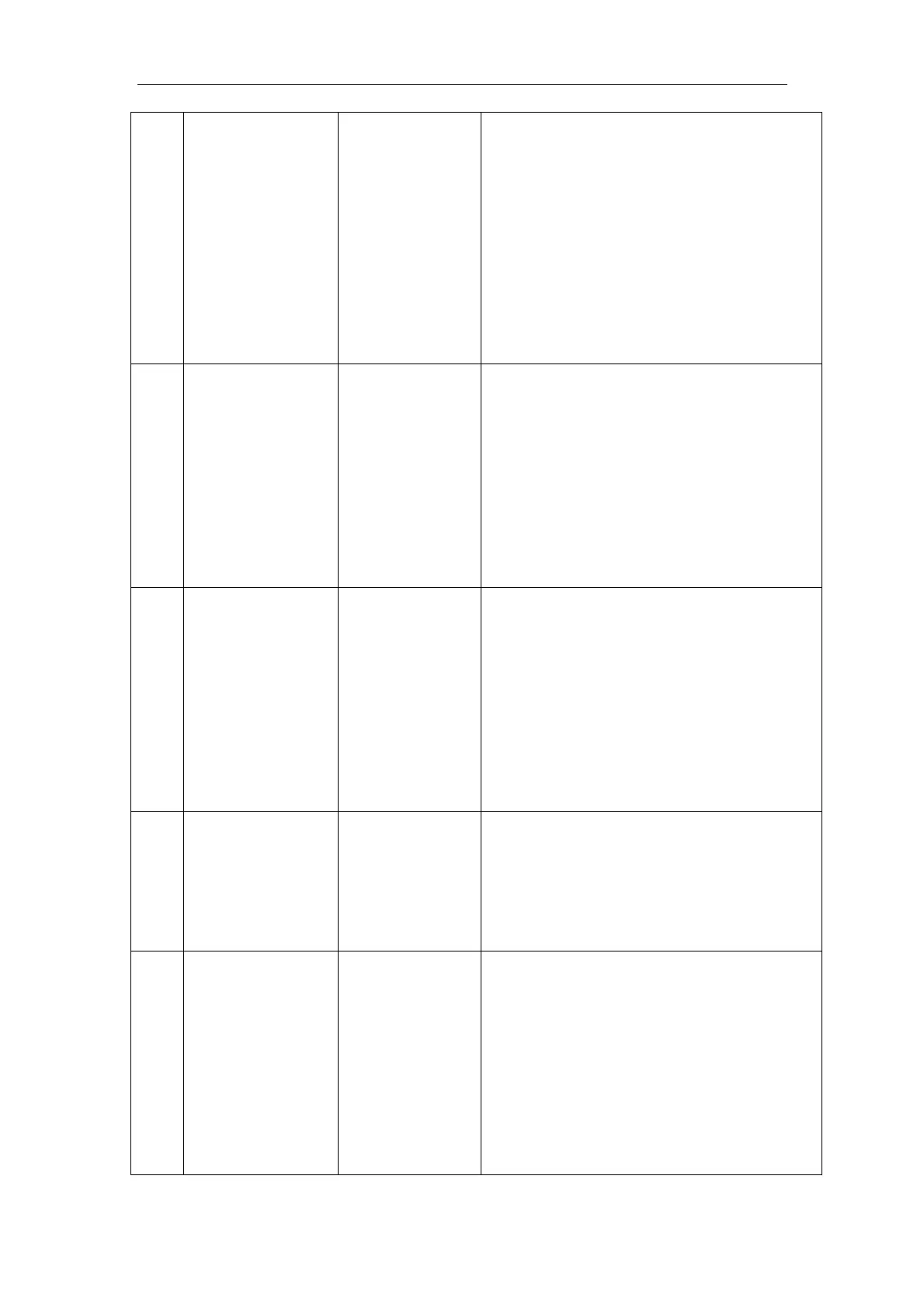

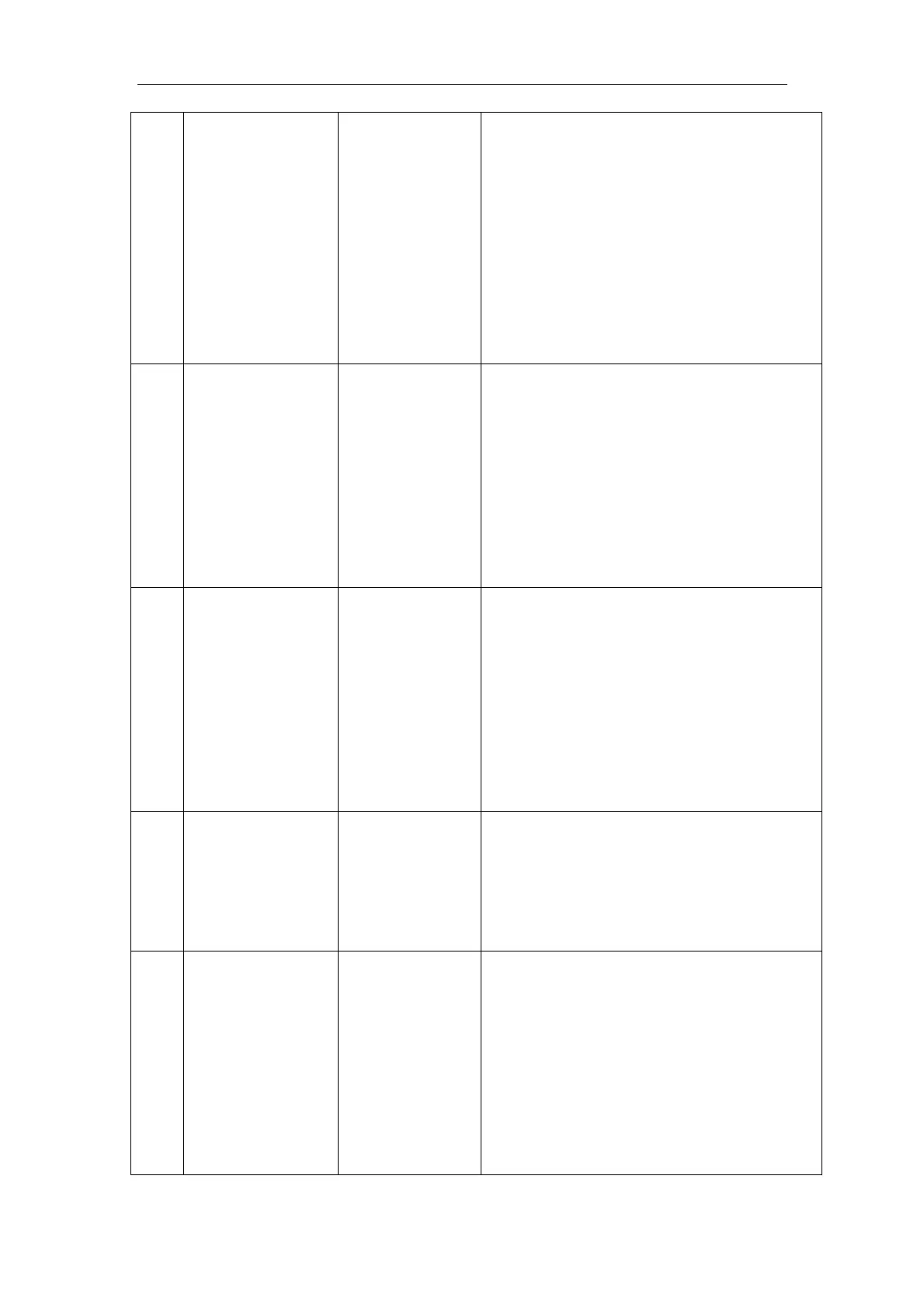

7 After IHS have

accomplished, auto

arc start is closed.

Plasma power

source can not start

arc start, or arc

start relay is not

closed

1. Coming back THC arc start relay wiring,

make two wiring which control plasma power

source start arc start connect, observe whether

plasma can make arc start work normally.

2. If plasma can make arc start work normally,

user should check whether THC arc start relay

can be closed normally(when the button named

【ARCON TEST】is pressed, arc start relay

should be closed).

8 Torch can not start

arc start

1. Confirming the plasma power source is

working

2. Check whether IHS height is too high(or

low)

3. Check torch part which it is easy to damage.

4. When torch retaining cap is sensing,

electrode and the nozzle have scum which made

by cutting, it can make short circuit happen.

9 When CNC make

torch start work,

torch decline

immediately.

When CNC make

torch start work

and arc voltage is

too high, if auto

height control start

work, torch will

decline

immediately.

1. Increasing arc voltage setting value.

2. Extending the time which CNC start auto

height control need spend.

3. Check whether the corner low speed signal

of CNC or auto signal is normal, in genal, auto

height control signal is not joined before torch

cut a few millimeters.

10 After arc have

shifted and piercing

have accomplished,

plasma make arc

start stop to work.

1. Delay time is too long.(before torch

machine move, torch stay time is too long in

piercing position, plasma is easy to make arc

start stop to work)

11 When auto IHS

work, torch is not

uplifted after it

collide steel plate.

THC do not

receive collision

signal or IHS

height is too small.

1. Check whether collision signal can work

normally(check whether proximity switch or

torch retaining cap can reflect the collision

situation normally). If it can not reflect the

collision situation normally, IHS will not be

accomplished.

2. Check whether positioning height time

setting is too small, if this setting value is too

Loading...

Loading...