Portable Plasma Torch Height Controller Manual (F1620)

37

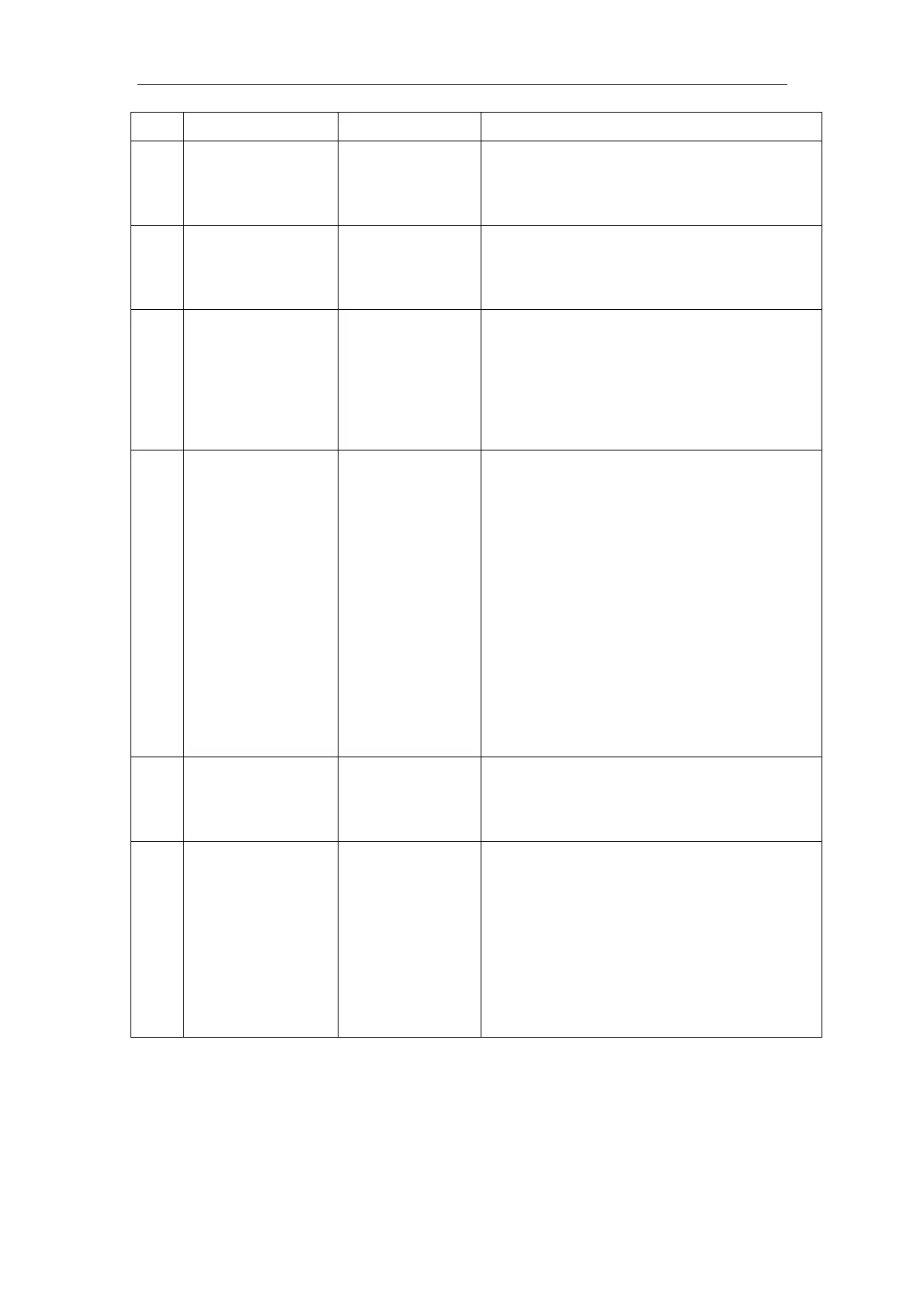

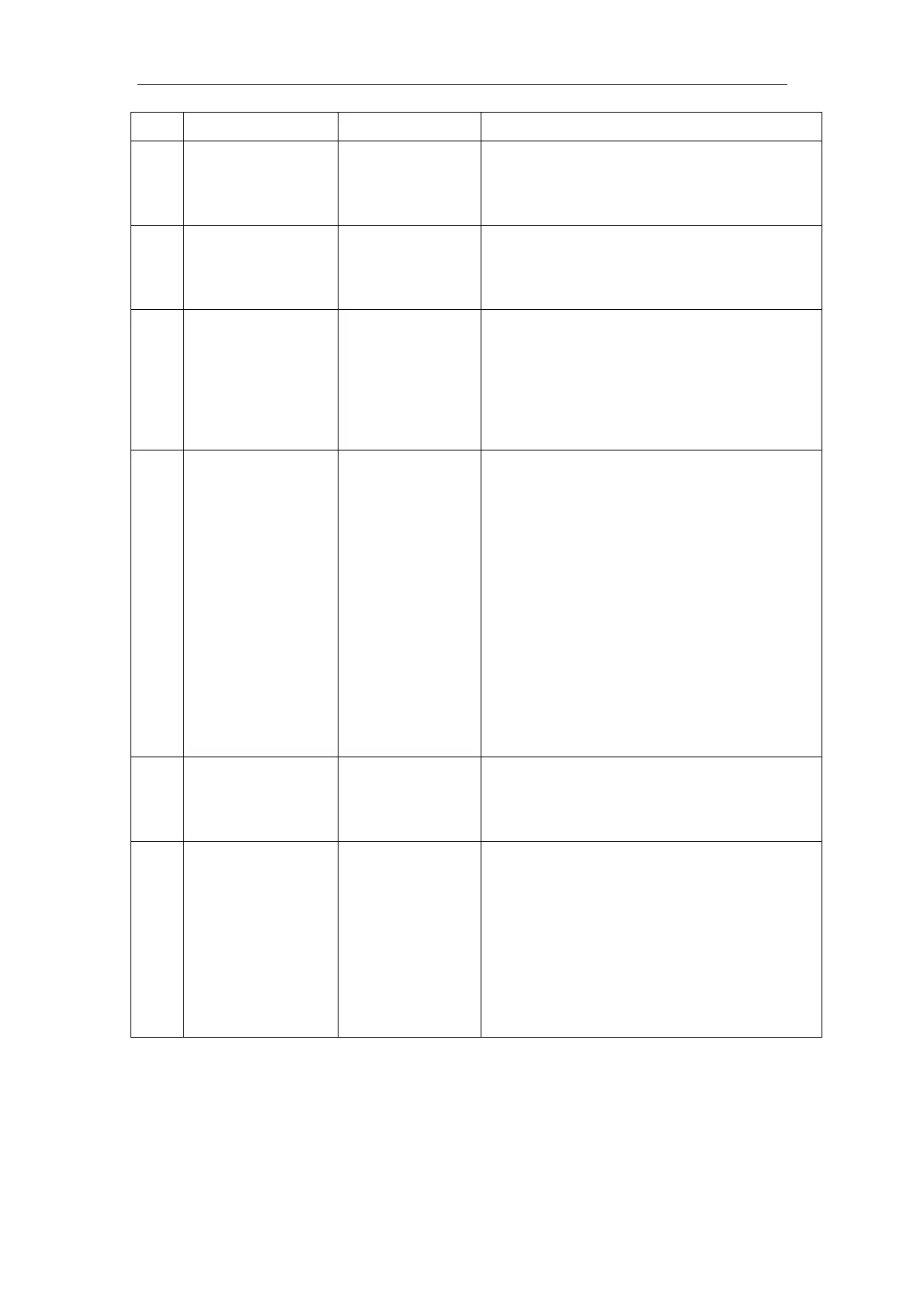

small, gun will not be uplifted.

12 Torch is easy to

collide steel plate

during torch work

Arc voltage setting

is too small

Increasing the arc voltage setting point

13 During auto height

control work, torch

is easy to vibrate

The THC

sensitivity is too

high

Reducing the sensitivity coefficient P07 slightly

14 When touch work in

the relatively steep

slope, arc voltage

follow speed is too

small

The THC

sensitivity is too

small, or lifting

motor speed is too

small

1. Increasing sensitivity coefficient P07

slightly

2. Changing lifting motor which have faster

speed

15 Arc breaking is

happened during

torch work, CNC do

not make torch stop

work right away

After plasm arc

breaking have

happened, arc

voltage do not

decline right away.

After THC receive

this signal, it think

arc start is working

normally, and do

not send arc

breaking signal

CNC can receive arc feedback signal which

make by plasma

16 The green nixie tube

display LIC after

starting up

Data storage go

wrong

User should post it back our factory, we can

repair it.

17 When program is

upgrading, after

pressing the enter

key, the machine do

not work and do not

accomplish the

upgrade.

USB read-write

speed does not

match

1. Please upgrade again after powering off .

2. Please upgrade again after replacing the

USB flash disk.

Loading...

Loading...