The No. 1 bearing housing is on the aft side

of the inner shell of the front frame. The bear-

ing is a spherical, self-aligning roller bearing

designed to absorb any misalignment of the

forward compressor shaft. Three of the front

frame struts are oversized and contain the No.

1 bearing service lines. The ten o’clock strut

houses the bearing oil supply tube, the two o’-

clock strut houses a sump vent tube, and the

six o’ clock strut houses an oil scavenge tube.

A variable inlet guide vane is mounted aft of

each of the front frame struts. The outer ends

of the movement of the actuator ring will cause

movement of the inlet guide vanes to direct air-

flow to the first-stage rotor blades at the proper

angle. The actuator ring and inlet guide vanes

are positioned by the variable geometry actu-

ators, which utilize high-pressure fuel from the

engine fuel control unit.

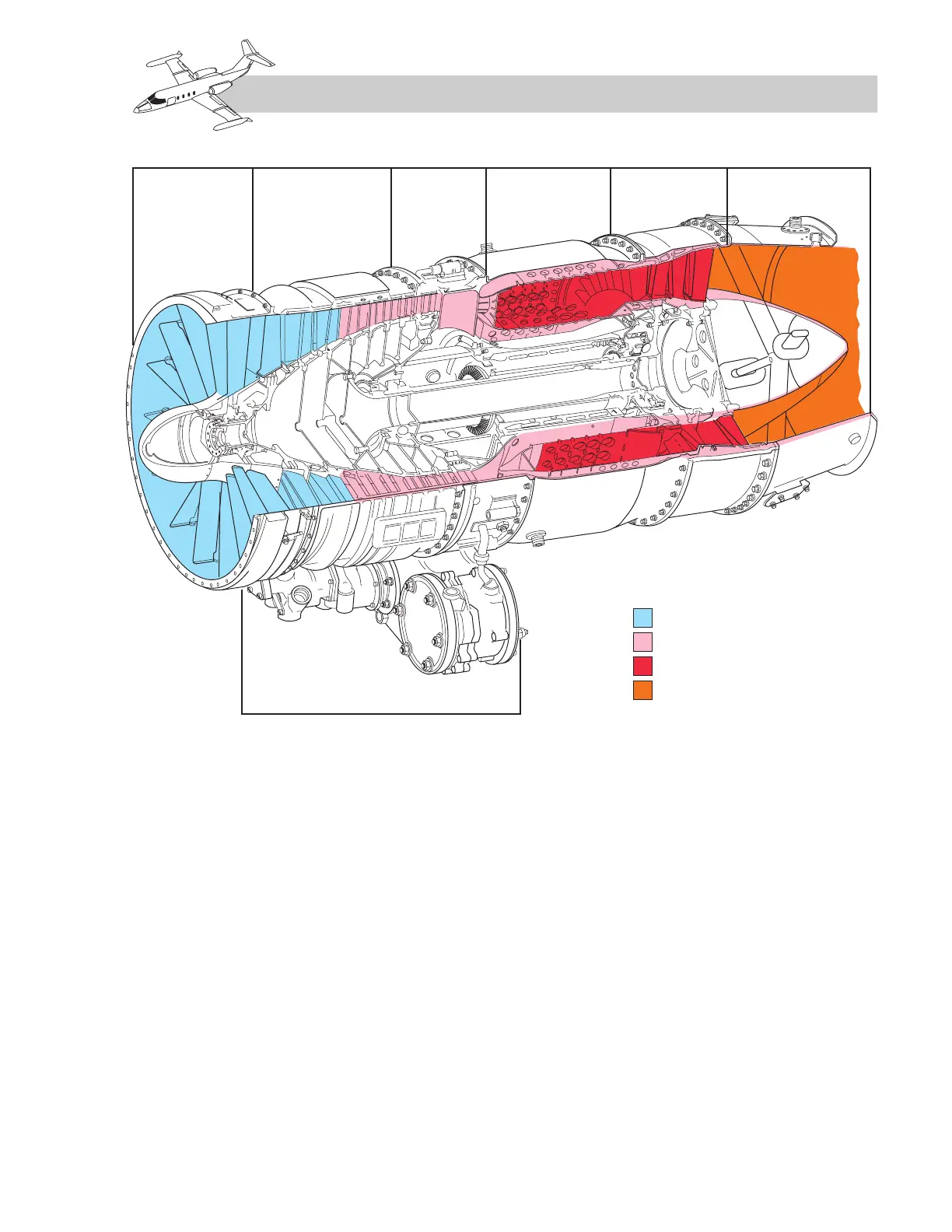

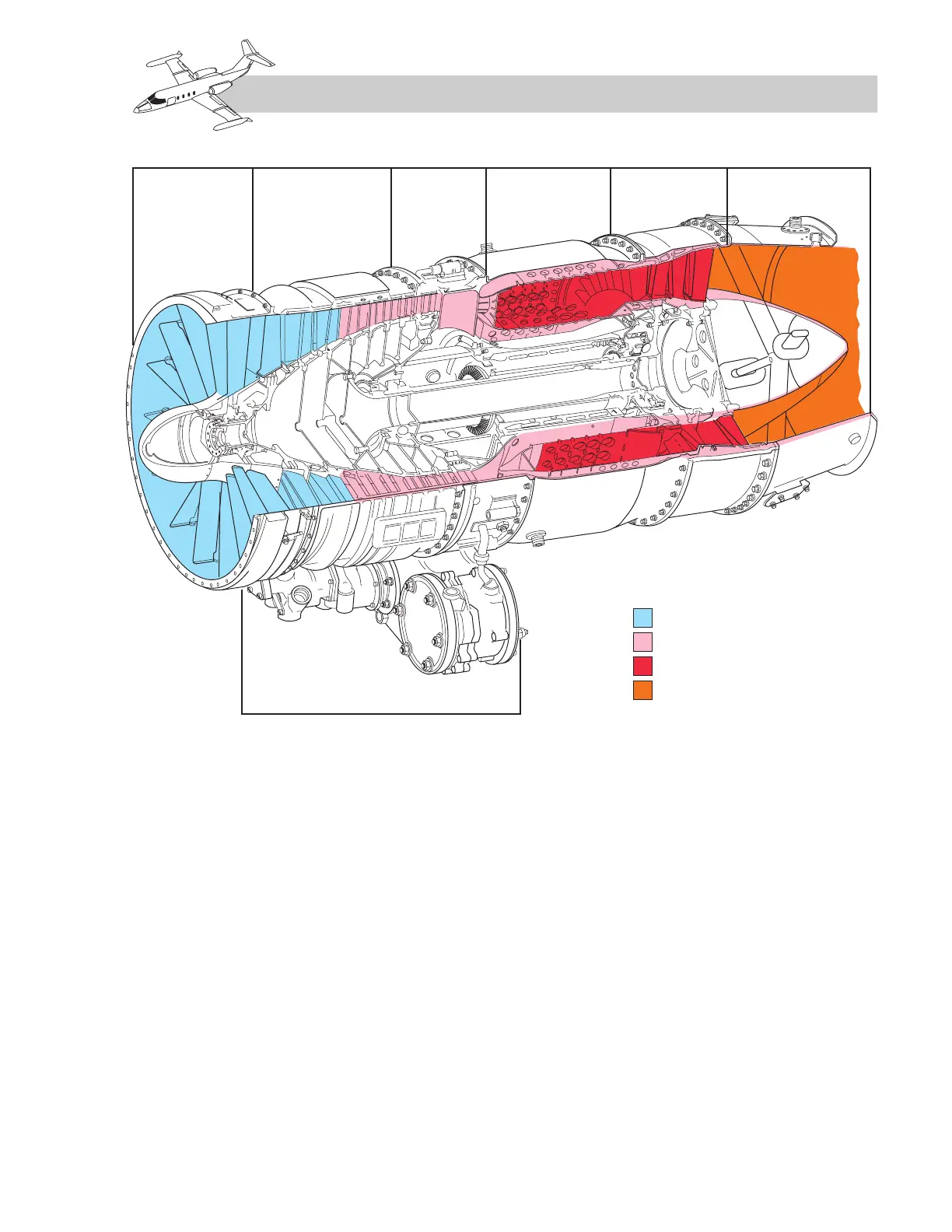

Compressor

The compressor (Figure 7-3) is an eight-stage

axial-flow unit consisting of rotors and stators.

It functions to increase the pressure of the

inlet air and direct the airflow rearward. The

stator casing assembly which surrounds the

compressor rotor assembly consists of a com-

pressor casing upper half and lower half with

seven stages of stator vanes. The compressor

casing is an annular chromalloy component,

split and flanged along the horizontal cen-

terline and reinforced externally

by integral

7-3

FOR TRAINING PURPOSES ONLY

Loading...

Loading...