LEGA

LEGA LEGA

LEGA

srl

srlsrl

srl

C

CC

Costruzioni

ostruzioni ostruzioni

ostruzioni A

AA

Apistiche

pistichepistiche

pistiche

–

––

–

via Maestri del Lavoro 23

via Maestri del Lavoro 23 via Maestri del Lavoro 23

via Maestri del Lavoro 23 –

––

–

48018 Faenza

48018 Faenza48018 Faenza

48018 Faenza

www.legaitaly.com

www.legaitaly.com www.legaitaly.com

www.legaitaly.com -

--

-

Tel 054626834

Tel 054626834 Tel 054626834

Tel 054626834 –

––

–

Fa

FaFa

Fax 054628279

x 054628279 x 054628279

x 054628279 –

––

–

P.iva 00043230390

P.iva 00043230390P.iva 00043230390

P.iva 00043230390

22 / 68

‘Tempo dosata’

(batching time) is the honey packing time.

‘Tempo sosta dopo dosata’

(waiting time after batching) is the time that elapses between honey packing end

and turntable restart.

These values are valid with the packer set for 1, 2 or 4 packing cycles.

6) Use the R.-H. direction arrow (2) to highlight the value to change.

7) Use the UP (1) or DOWN (4) arrow keys to adjust the value.

8) After entering the new data, press OK (5) to store the changes.

9) Use the arrow UP (1) or arrow DOWN (4) keys to switch from the T.DOSE (batching time) screen display

to the T.RUOTE (waiting time after batching) or the PRUDUCI 1 screen displays; after completing the

new data entry press OK (5) to store the changes.

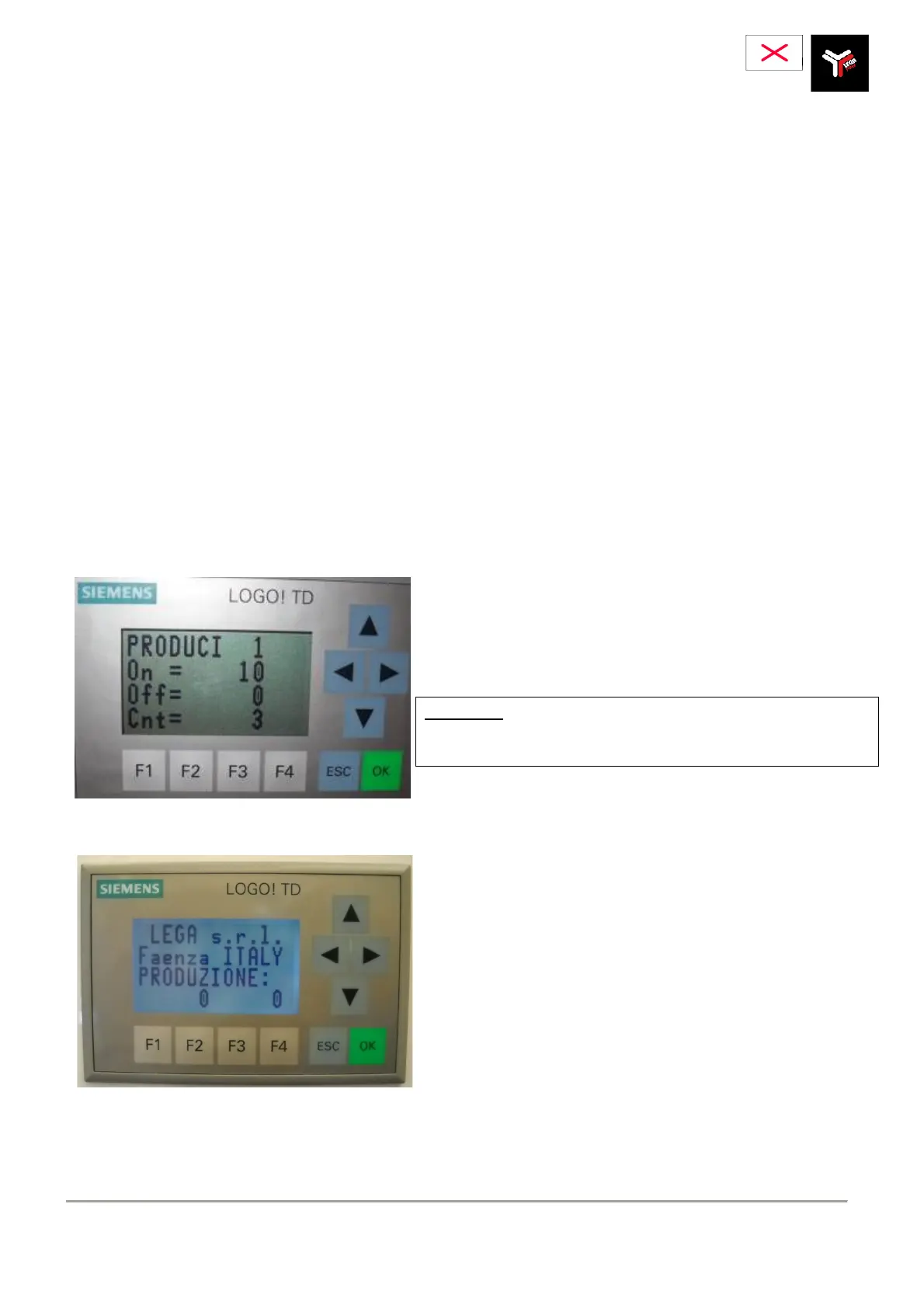

10) From the PRODUCI 1 screen display (pictured on page 7), it is possible to set the number of jars to fill by

adjusting the item “On” using the direction arrows. The item “Off” may not be modified, while the item

“Cnt” refers to the number of jars filled during the work cycle.

11) Press the ESC (6) key twice. The home page will be displayed. The machine is now ready to work

according to your newly entered values.

12) At the end of each work cycle, reset the screen display by holding down the emergency resetting control

(page 10, item 26) for approximately 10 seconds.

By selecting F4 followed by the R.-H. direction arrow (2), the

machine troubleshooting screen will be displayed which

can be checked over the phone with one of our

technicians in case of faults.

WARNING!

WARNING!WARNING!

WARNING!

The supplier declines all responsibility for any

The supplier declines all responsibility for any The supplier declines all responsibility for any

The supplier declines all responsibility for any

software fault resu

software fault resusoftware fault resu

software fault resulting from incorrect use or failure to

lting from incorrect use or failure to lting from incorrect use or failure to

lting from incorrect use or failure to

comply with directions.

comply with directions.comply with directions.

comply with directions.

4.1.1 Instructions for resetting product

4.1.1 Instructions for resetting product4.1.1 Instructions for resetting product

4.1.1 Instructions for resetting production

ionion

ion

capacity

capacitycapacity

capacity

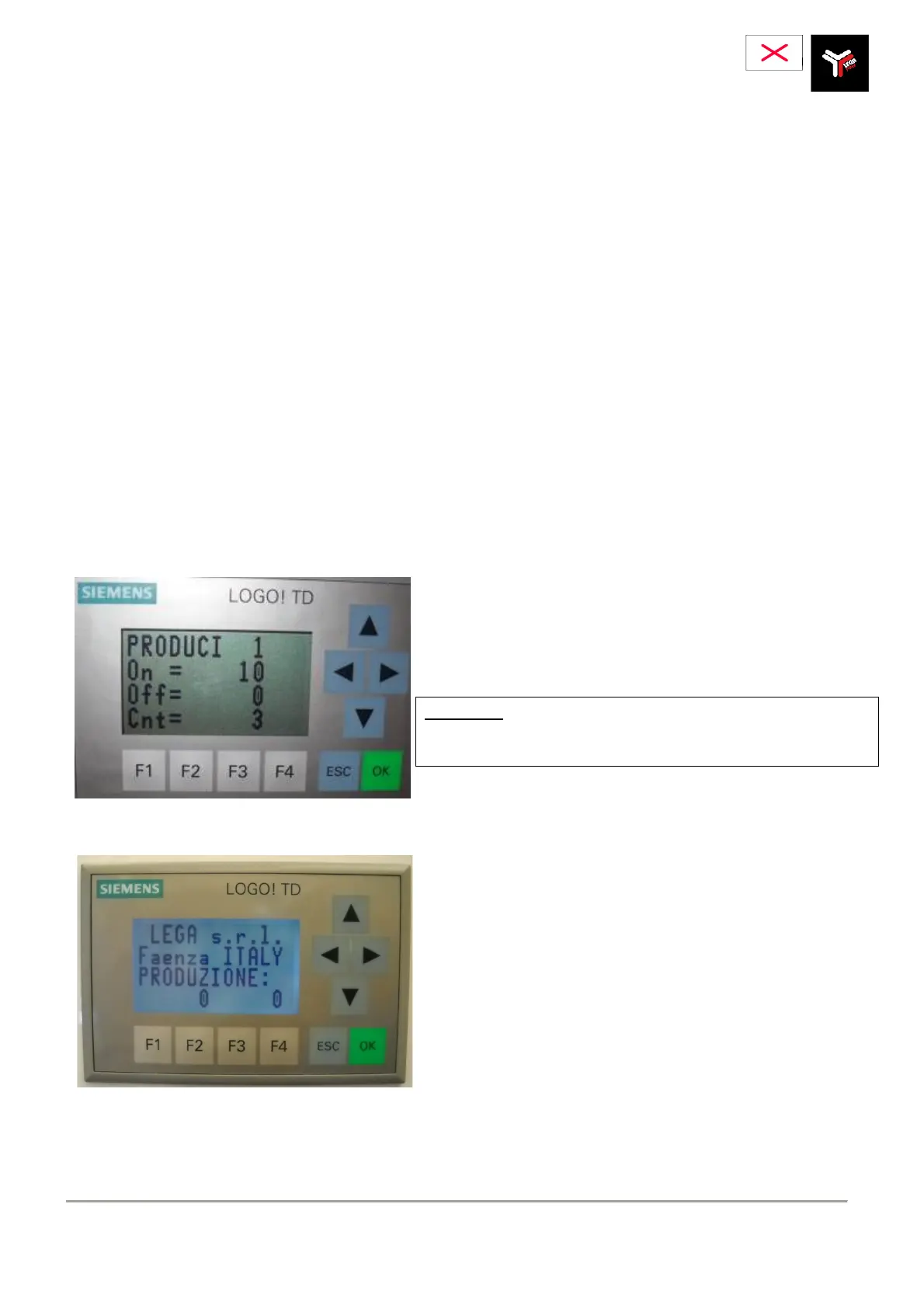

Press F1 to view the screen shown here.

The first figure on the left shows daily production, the second

figure on the right shows total number of jars filled.

To reset the first figure, press and hold down the

“EMERGENCY RESET” key for more than three seconds.

To reset the second figure, press and hold down the

“EMERGENCY RESET” key for more than ten seconds.

If total number of jars filled is set to 999.999, the machine will

stop and regular work will be prevented.

It this case it will be necessary to reset the machine as

explained above.

Loading...

Loading...