Page 18

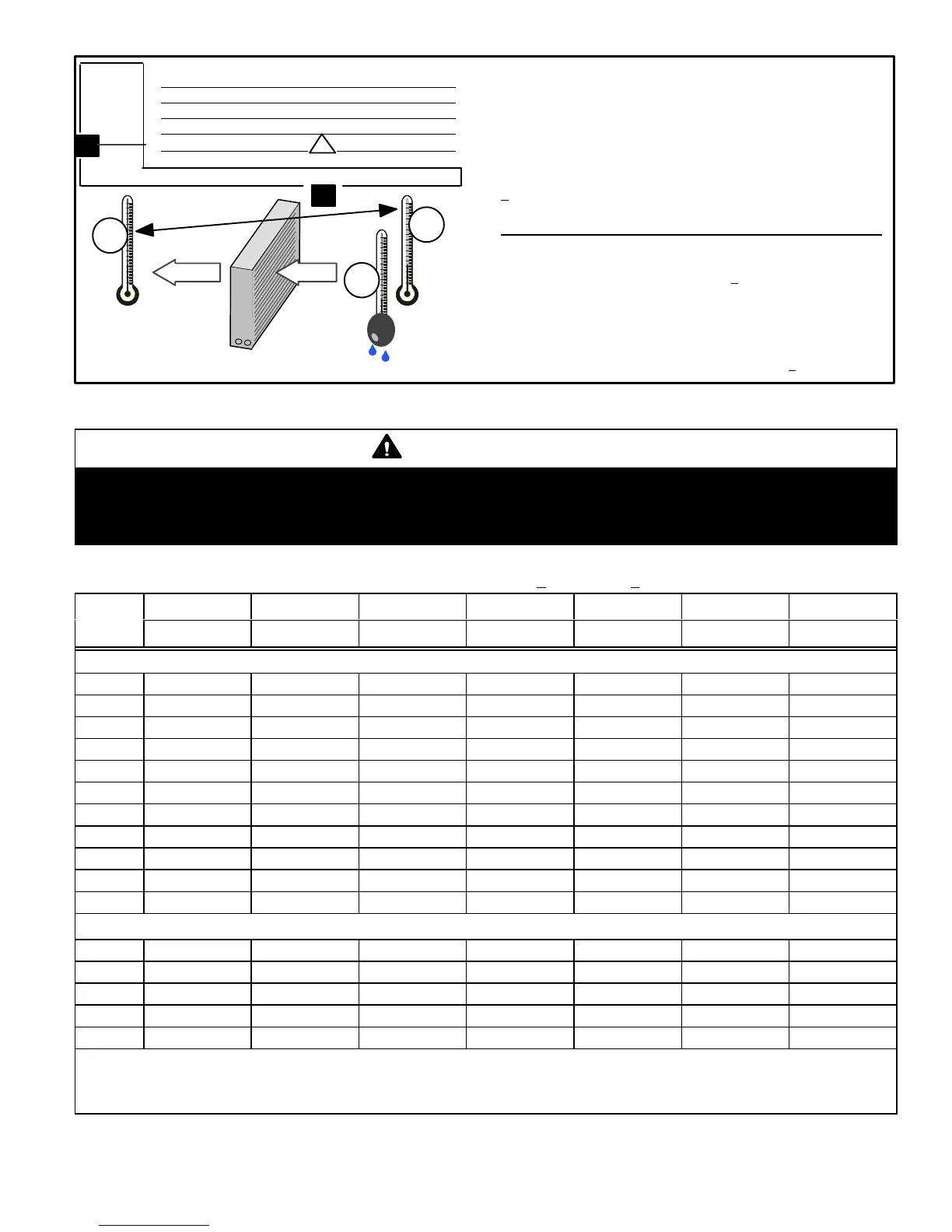

FIGURE 18

Step 1. Determine the desired DTMeasure entering air tempera-

ture using dry bulb (A) and wet bulb (B). DT is the intersecting value

of A and B in the table (see triangle).

Step 2. Find temperature drop across coilMeasure the coil’s dry

bulb entering and leaving air temperatures (A and C). Temperature

Drop Formula: (T

Drop

) = A minus C.

Step 3. Determine if fan needs adjustmentIf the difference be-

tween the measured T

Drop

and the desired DT (T

Drop

–DT) is within

+

3º, no adjustment is needed. See examples: Assume DT = 15 and

A temp. = 72º, these C temperatures would necessitate stated ac-

tions:

Cº T

Drop

– DT = ºF ACTION

53º 19 – 15 = 4 Increase the airflow

58º 14 – 15 = −1 (within +

3º range) no change

62º 10 – 15 = −5 Decrease the airflow

Step 4. Adjust the fan speedSee indoor unit instructions to in-

crease/decrease fan speed.

Changing air flow affects all temperatures; recheck temperatures to

confirm that the temperature drop and DT are within +

3º.

DT

80 24 24 24 23 23 22 22 22 20 19 18 17 16 15

78 23 23 23 22 22 21 21 20 19 18 17 16 15 14

76 22 22 22 21 21 20 19 19 18 17 16 15 14 13

74 21 21 21 20 19 19 18 17 16 16 15 14 13 12

72 20 20 19 18 17 17 16 15 15 14 13 12 11 10

70 19 19 18 18 17 17 16 15 15 14 13 12 11 10

57 58 59 60 61 62 63 64 65 66 67 68 69 70

Temp.

of air

entering

indoor

coil ºF

INDOOR

COIL

DRY BULBDRY

BULB

WET

BULB

B

T

Drop

19º

A

Dry−bulb

Wet−bulb ºF

A

72º

B

64º

C

53º

air flowair flow

All temperatures are

expressed in ºF

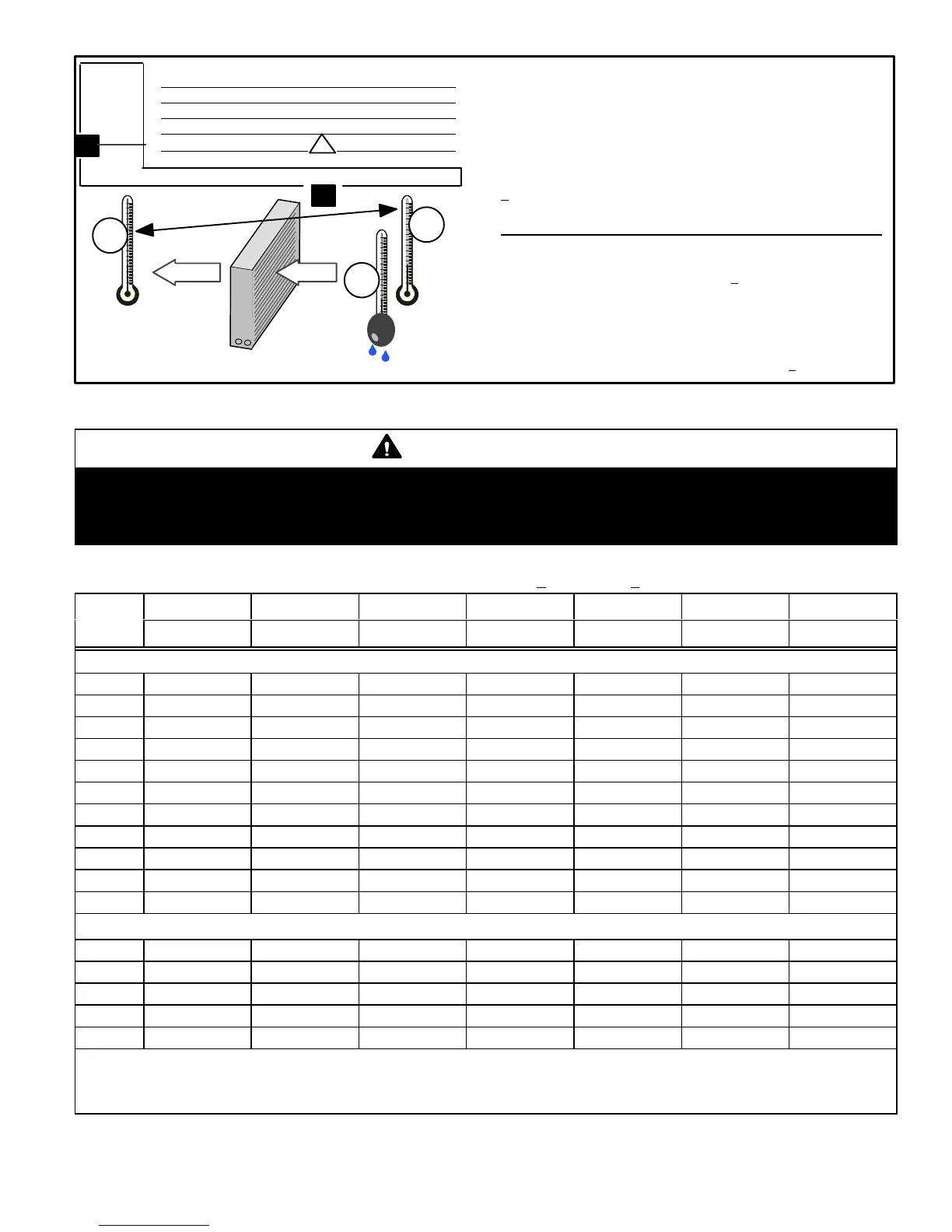

C − Pre− Charge Maintenance Checks

IMPORTANT

Use table 5 as a general guide when performing maintenance checks. This is not a procedure for charging the

unit (Refer to Charging / Checking Charge section). Minor variations in these pressures may be expected due

to differences in installations. Significant differences could mean that the system is not properly charged or that

a problem exists with some component in the system.

Table 5

Normal Operating Pressures − Liquid +

10 & Vapor +5 PSIG*

14HPX−018 14HPX−024 14HPX−030 14HPX−036 14HPX−042 14HPX−048 14HPX−060

5F (5C)**

Liquid / Vapor Liquid / Vapor Liquid / Vapor Liquid/ Vapor Liquid / Vapor Liquid / Vapor Liquid / Vapor

Cooling

65 (18) 226 / 140 233 / 137 238 / 138 220 / 138 223 / 125 231 / 136 243 / 136

70 (21) 244 / 141 252 / 138 263 / 139 236 / 140 241 / 130 248 / 139 263 / 137

75 (24) 263 / 142 271 / 140 279 / 139 256 / 141 261 / 134 271 / 140 282 / 138

80 (27) 283 / 143 292 / 141 299 / 140 276 / 142 282 / 138 291 / 142 306 / 139

85 (29) 302 / 144 314 / 142 324 / 141 298 / 143 302 / 139 312 / 143 327 / 140

90 (32) 328 / 145 338 / 143 340 / 142 321 / 144 326 / 140 335 / 144 351 / 141

95 (35) 351 / 146 361 / 145 375 / 145 344 / 144 349 / 141 359 / 145 376 / 142

100 (38) 376 / 147 387 / 146 397 / 145 369 / 146 374 / 142 384 / 146 401 / 143

105 (41) 402 / 148 412 / 147 424 / 147 394 / 147 399 / 143 411 / 148 426 / 145

110 (38) 430 / 149 441 / 148 454 / 150 421 / 148 428 / 145 439 / 149 452 / 146

115 (45) 465 / 150 471 / 151 485 / 150 449 / 149 455 / 146 468 / 150 484 / 148

Heating

60 (15) 346 / 139 352 / 138 338 / 137 350 / 134 373 / 139 355 / 130 351 / 117

50 (10) 323 / 117 331 / 114 334 / 112 331 / 117 363 / 117 336 / 113 333 / 105

40 (4) 306 / 98 304 / 99 312 / 93 313 / 97 348 / 97 315 / 88 316 / 88

30 (−1) 278 / 84 299 / 80 302 / 74 298 / 83 336 / 74 296 / 72 308 / 70

20 (−7) 273 / 66 283 / 66 280 / 53 284 / 66 322 / 64 286 / 64 300 / 61

*IMPORTANTThese are most−popular−match−up pressures. Indoor match up and indoor load cause

pressures to vary.

**Temperature of the air entering the outside coil (outdoor ambient temperature).

Loading...

Loading...