# 48306B006 Page 5

Installing Refrigerant Line

During the installation of an air conditioning system, it is

important to properly isolate the refrigerant line to prevent

unnecessary vibration. Line set contact with the structure

(wall, ceiling, or floor) may cause objectionable noise

when vibration is translated into sound. As a result, more

energy or vibration can be expected. Close attention to

line set isolation must be observed.

Following are some points to consider when placing and

installing a high-efficiency outdoor unit:

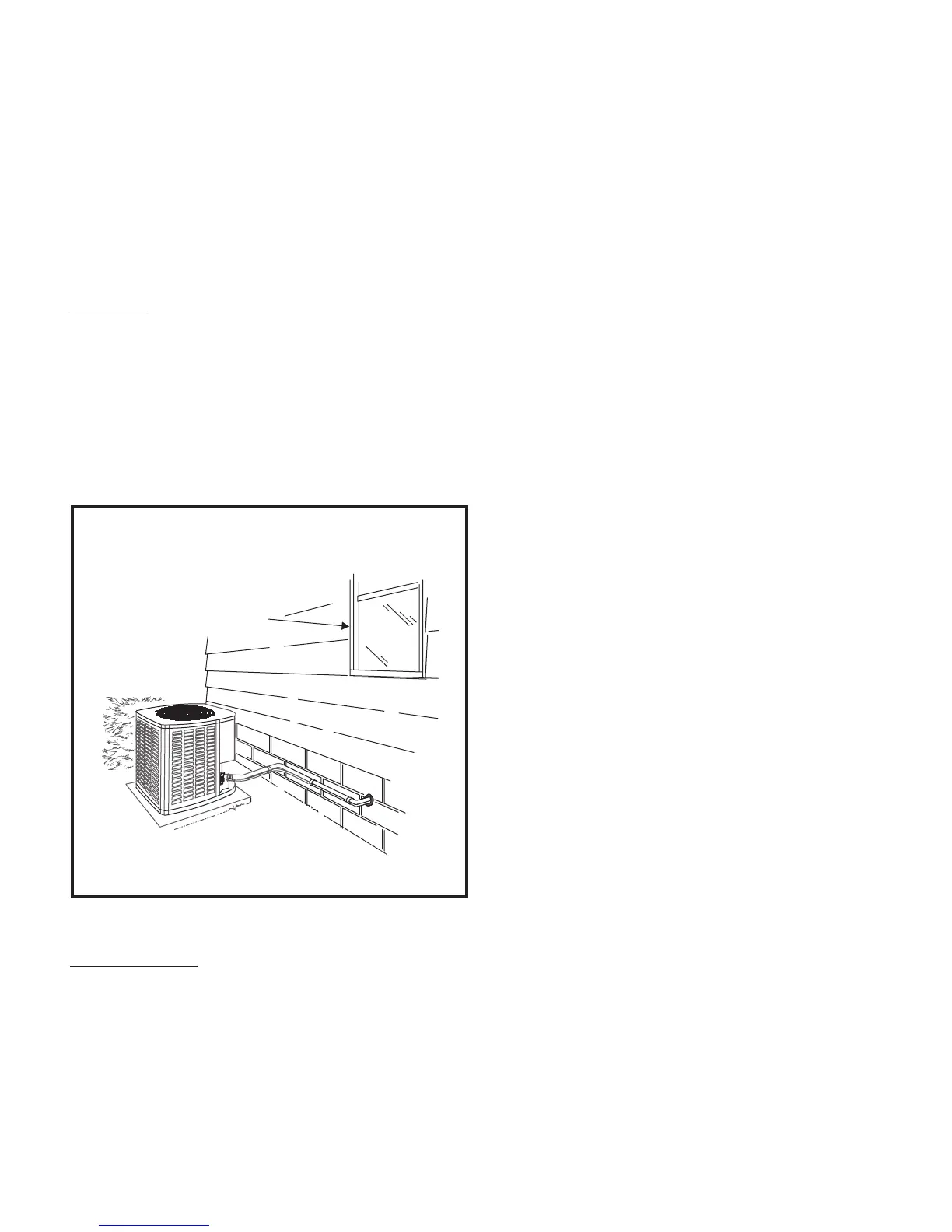

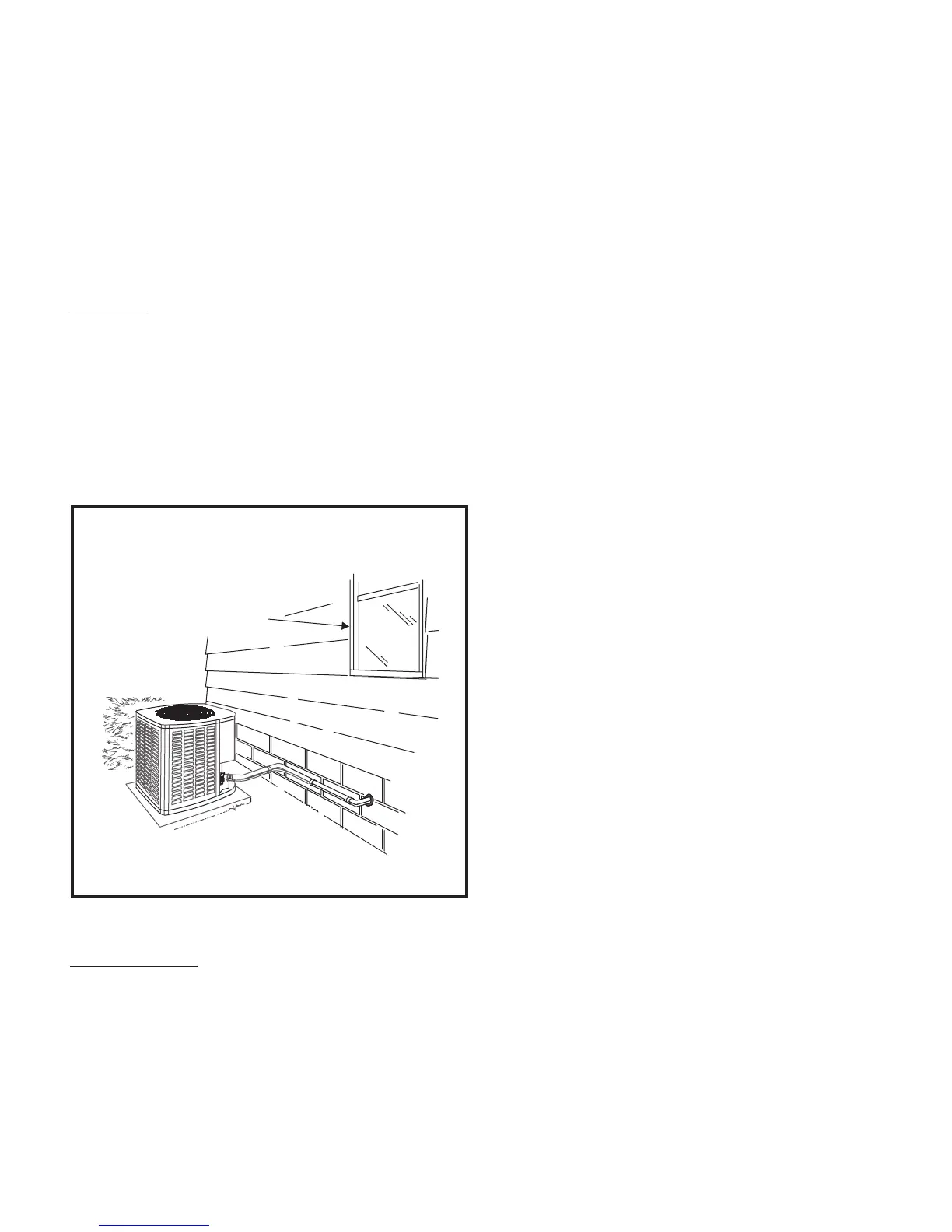

Placement

Be aware that some localities are adopting sound ordi-

nances based on how noisy the unit is at the neighbor’s

home, not at the original installation. Install the unit as far as

possible from the property line. When possible, do not

install the unit directly outside a bedroom window. Glass

has a very high level of sound transmission. Figure 5

shows how to place the outdoor unit and line set to reduce

line set vibration.

Line Set Isolation

Illustrations on the pages 6 and 7 demonstrate procedures

which ensure proper refrigerant line set isolation. Figure 6

shows how to install line sets on horizontal runs. Figure 7

shows how to make a transition from horizontal to vertical.

Figure 8 shows how to install line sets on vertical runs.

Brazing Connection Procedure

1. Cut ends of refrigerant lines square (free from nicks

or dents). Debur the ends. The pipe must remain

round; do not pinch end of line.

2. Before making line set connections, use dry nitrogen to

purge the refrigerant piping. This will help to prevent

oxidation and the introduction of moisture into the system.

3. Use silver alloy brazing rods (5% or 6% silver alloy for

copper-to-copper brazing or 45% silver alloy for

copper-to-brass or copper-to-steel brazing) which are

rated for use with HCFC-22 refrigerant.

4. Remove the Schrader core assemblies before brazing

to protect them from damage due to extreme heat.

Replace the cores when brazing is complete.

5. Wrap a wet cloth around the valve body and copper tube

stub to protect them from heat damage during brazing.

Wrap another wet cloth underneath the valve body to

protect the base paint.

6. Braze the line set to the service valve. Quench the joints

with water or a wet cloth to prevent heat damage to the

valve core and opening port. The tube end must stay

bottomed in the fitting during final assembly to

ensure proper seating, sealing, and rigidity.

7. Install the factory-supplied fixed orifice (or thermal

expansion valve which is sold separately and which is

approved for use with HCFC-22 refrigerant) in the

liquid line at the indoor coil.

Refrigerant Metering Device

2SHP13 units are designed for use with either fixed orifice

or TXV systems. Refer to the appropriate following section

for information on installing the chosen refrigerant meter-

ing device.

Fixed Orifice Systems

2SHP13 units are shipped with a fixed orifice refrigerant

metering device. Replace the existing indoor unit fixed

orifice with the orifice supplied with this unit. Place the

supplied fixed orifice sticker on the indoor cabinet after

installation. See Table 3 on page 7 for the proper fixed

orifice size for each unit. In nonstandard applications, the

provided fixed orifice may not be appropriately sized.

Install the fixed orifice as shown in Figure 9 on page 7. Do not

twist cap tubes when loosening the seal nut from the orifice

housing. Use wrench to back up the distributor.

Outside Unit Placement

and Installation

Figure 5

Install unit away

from windows

Two 90° elbows installed in lineset

will reduce lineset vibration

Loading...

Loading...