Page 8 # 48306B006

Expansion Valve Systems

Expansion valves equipped with Chatleff-type fittings are

available from the manufacturer. See Table 4 for proper

TXV for each unit.

To install an expansion valve (see Figure 9 on page 7):

1. Separate the distributor assembly and remove the

piston orifice and used teflon seal. Insert nozzle end

of the expansion valve along with a new teflon seal

into the distributor and tighten to 20 – 30 ft. lbs. Use

backup wrench on all wrench flats. Overtightening

will crush the teflon seal and may cause a leak.

2. Attach liquid line portion of distributor assembly along

with new teflon seal to the inlet of the expansion

valve. Tighten to 20 – 30 ft. lbs. Use backup wrench

on all wrench flats. Overtightening will crush the

teflon seal and may cause a leak.

3. Connect the external equalizer line to the equalizer

port on the suction line and tighten to 8 ft. lbs.

4. Strap the superheat sensing bulb to the suction header.

If installing an expansion valve on an indoor coil that

previously used a fixed orifice, be sure to remove the

existing fixed orifice. Failure to remove a fixed orifice

when installing an expansion valve to the indoor coil will

result in improper operation and damage to the system.

Manifold Gauge Set

When checking the unit charge, use a manifold gauge set

that is equipped with “low loss” hoses. Do not use a manifold

gauge set with anything other than a “low loss” hose.

Liquid and Suction Line Service Valves

The liquid line and suction line service valves (see Figure

10) and service ports are used for leak testing, evacuat-

ing, charging, and checking charge.

Each valve is equipped with a service port which has a

factory-installed Schrader valve. A service port cap

protects the Schrader valve from contamination and

serves as the primary leak seal.

To Access the Schrader Port:

1. Remove the service port cap with an adjustable wrench.

2. Connect gauge to the service port.

3. When testing is completed, replace service port cap.

Tighten finger tight, then an additional 1/6 turn.

To Open Liquid or Suction Line Service Valve:

1. Remove stem cap with an adjustable wrench.

2. Use a service wrench with a hex-head extension to

back the stem out counterclockwise as far as it will

go. Use a 3/16" hex head extension for liquid line

service valves and a 5/16" extension for suction line

service valves.

3. Replace the stem cap. Tighten finger tight, then

tighten an additional 1/6 turn.

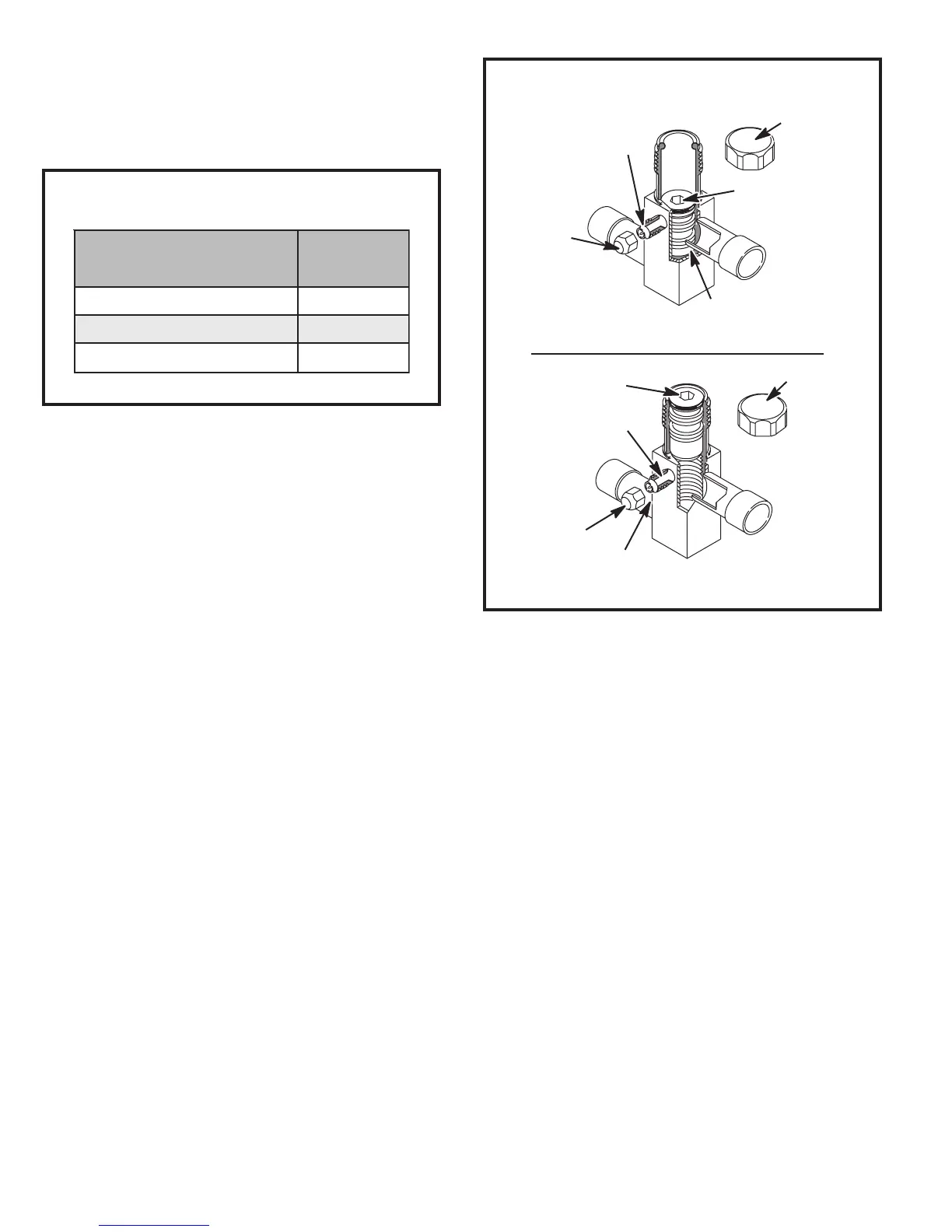

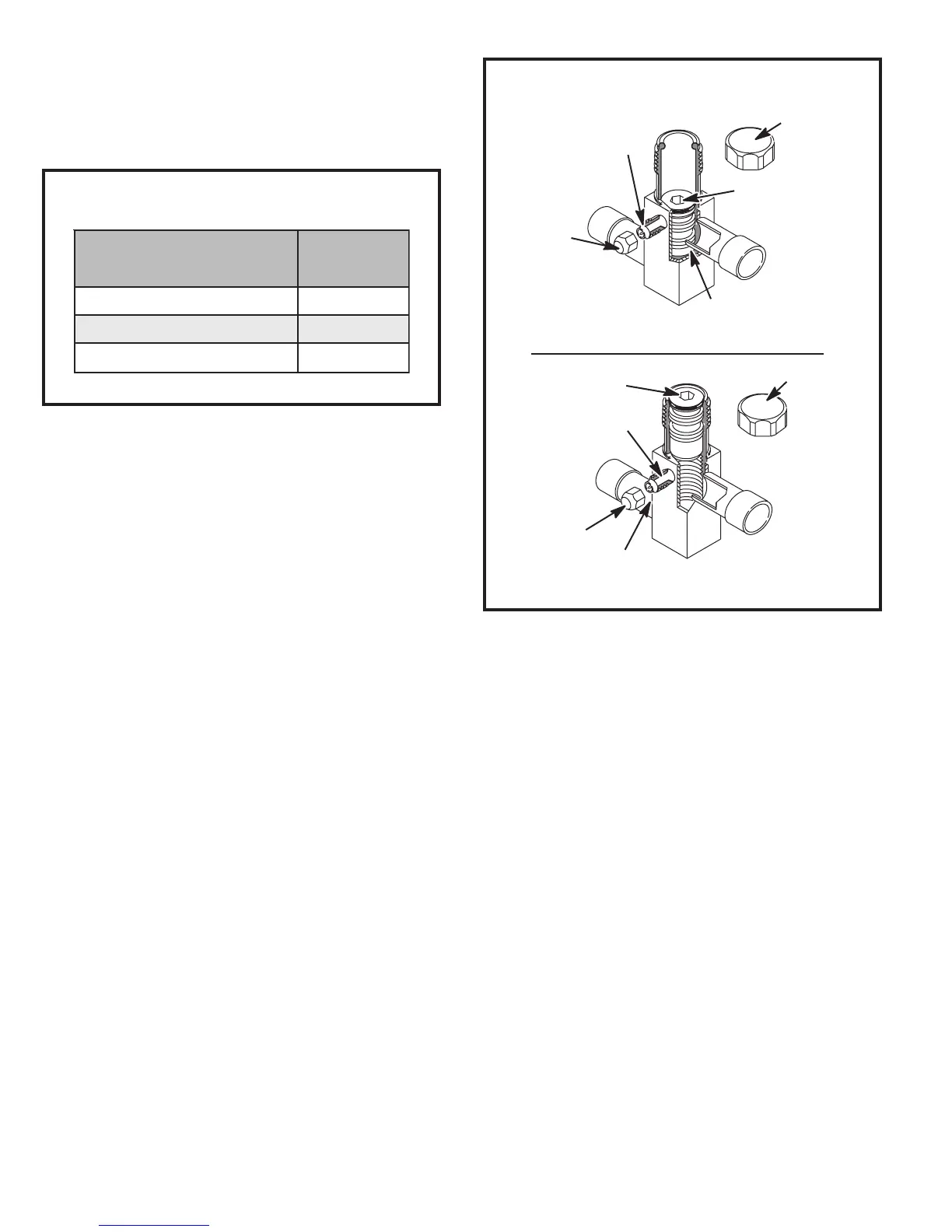

Figure 10

Service Valve

Valve Closed

Valve Open

Schrader

Valve

Schrader valve open

to line set when valve is

closed (front seated)

Service Port

Service

Port Cap

Insert hex

wrench here

(valve front seated)

To outdoor coil

To indoor coil

To indoor coil

Stem Cap

Service Port

To outdoor coil

Service Port Cap

Stem Cap

Insert hex

wrench here

Table 4

TXV Data

ledoM

traP

rebmuN

63-,03-,42-,81-31PHS210VXT2H

84-,24-31PHS2 20VXT2H

06-31PHS230VXT2H

Loading...

Loading...