Page 19

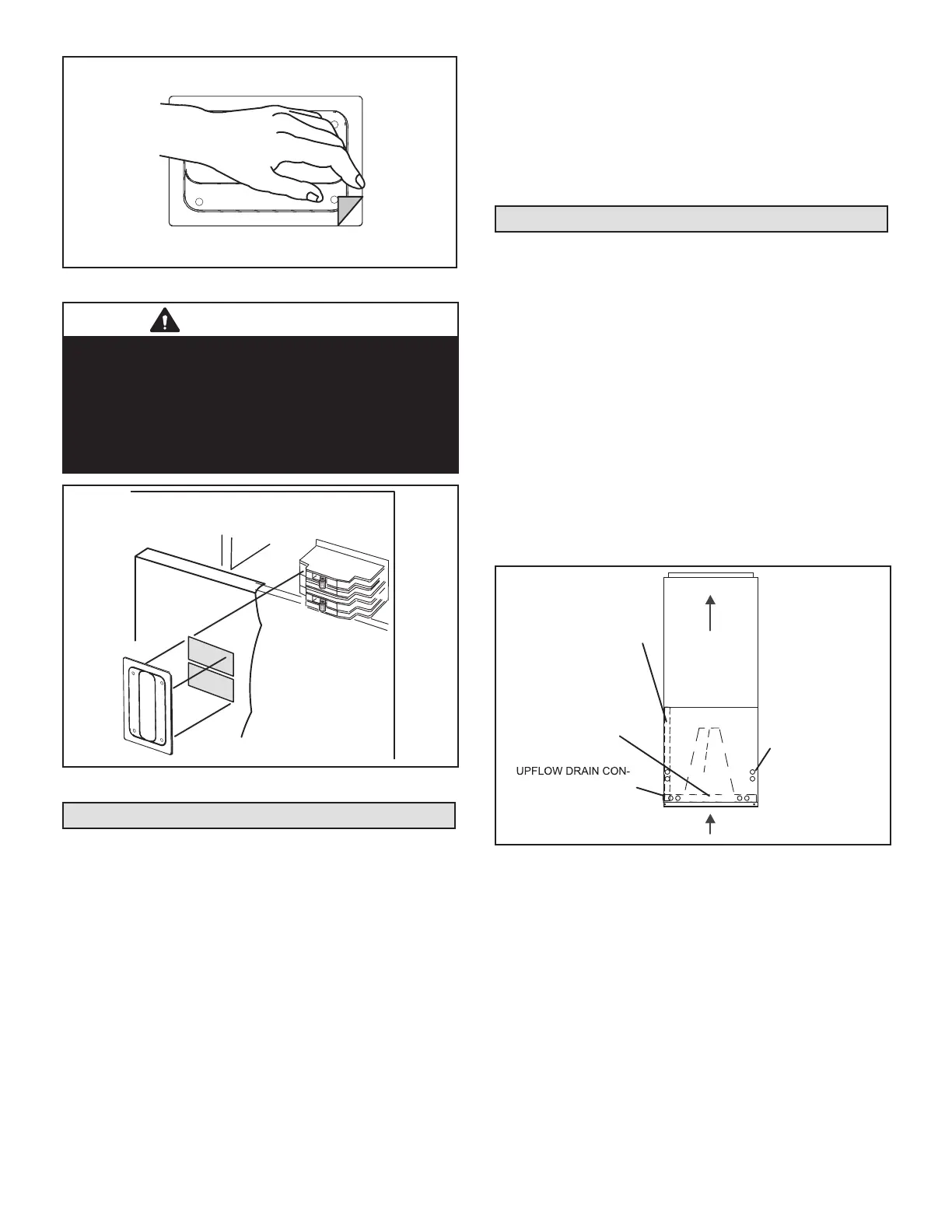

SIDE

VIEW

2” WIDE FOAM TA PE

DRIP SHIELD

1” WIDE FOAM TA PE (LONGER PIECE)

FIGURE 19. Applying Foam Tape to Drip Shield

COIL

DRIP SHIELD

DRIP PA N

FIGURE 20. Downow Drip Shields

6 - Replace the coil assembly and blower if you have

removed it. Replace the coil access panel.

7 - Set the unit so that it is level. Using sheet metal

screws, connect the return and supply air plenums

as required.

NOTE - For downow application, metal or Class I supply

and return air plenums must be used.

COMBUSTIBLE FLOOR

ADDITIVE BASE

PROPERLY SIZED

FLOOR OPENING

AIR

HANDER

UNIT

FIGURE 21. Downow Combustible Flooring Base

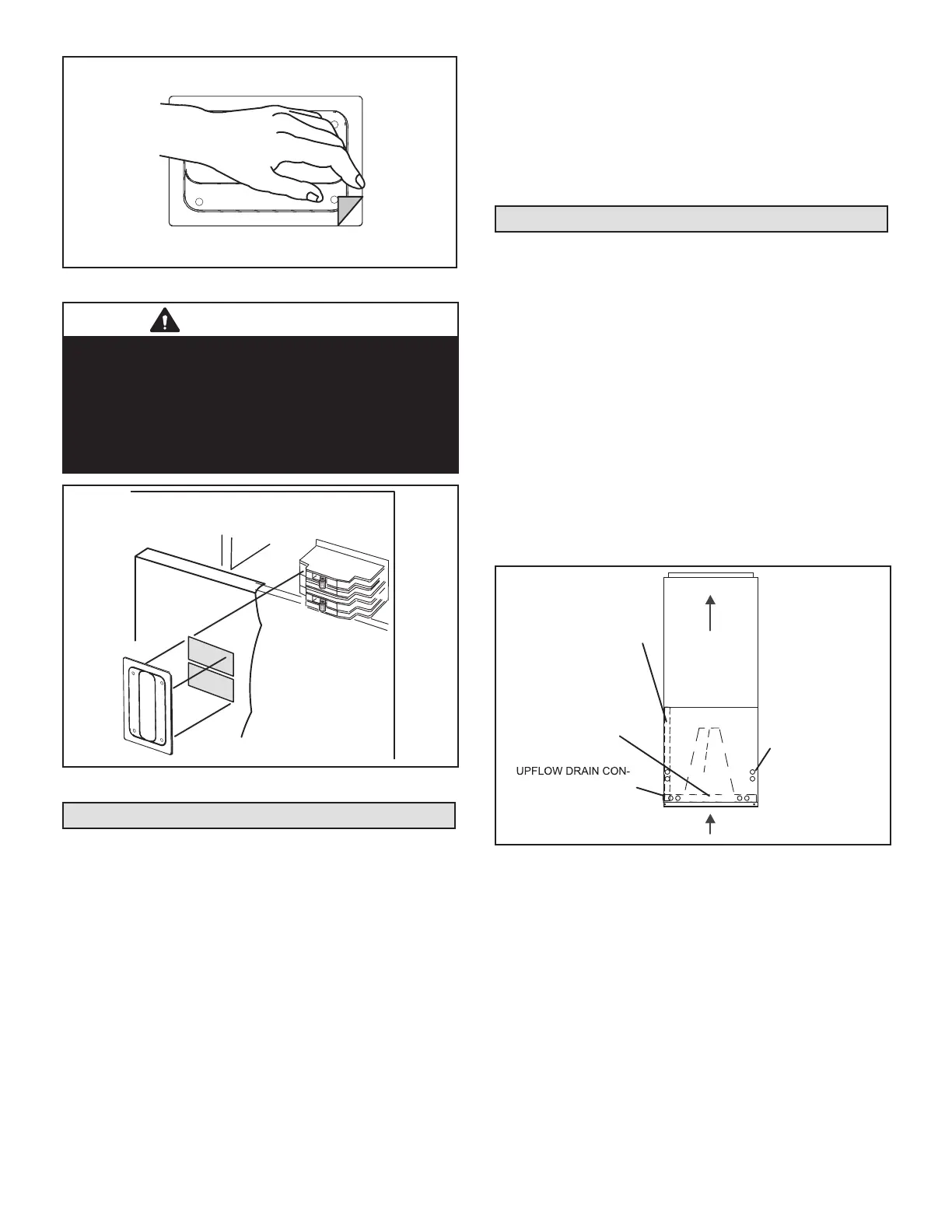

8 - For downow installation on combustible ooring,

an additive base must be used as illustrated in

gure 9. See CBA25UH Engineering Handbook for

downow combustible ooring base kits available

for this air handler.

9 - Cut an opening appropriately sized for combustible

base. Base dimensions are illustrated in gure 10.

After opening has been cut, set the additive base

into opening. Connect outlet air plenum to the

additive base. Set the unit on the additive base so

anges of the unit drop into the base opening and

seal against the insulation strips. The unit is now

locked in place. Install return air plenum and secure

with sheet metal screws.

TOP VIEW

OPENING

1‐5/8 (41)

1‐5/8 (41)

11‐3/8

(289)

3 (76)

1‐5/8 (41)

22‐5/8 (575) -018/024

24‐5/8 (625) -030, 036

26‐5/8 (676) -042, 048, 060

5/8 (16)

13‐1/2 (343)

SUPPLY AIR OPENING

INCHES (MM)

23-1/4 (591)

20 (508)

FIGURE 22. Downow Combustible Base Dimensions

Brazing Connections

WARNING

Polyol ester (POE) oils used with HFC-410A refrigerant

absorb moisture very quickly. It is very important that the

refrigerant system be kept closed as much as possible.

DO NOT remove line set caps or service valve stub caps

until you are ready to make connections.

WARNING

Danger of re. Bleeding the refrigerant

charge from only the high side may result

in pressurization of the low side shell and

suction tubing. Application of a brazing torch

to a pressurized system may result in ignition

of the refrigerant and oil mixture. Check the

high and low pressures before applying heat.

Loading...

Loading...