Page 24

NOTE – Do not use soft solder.

6. Reinstall the rubber grommets after brazing is nished.

7. Make sure outdoor unit has been put in place accord-

ing to the Installation Instructions and is connected to the

refrigerant lines.

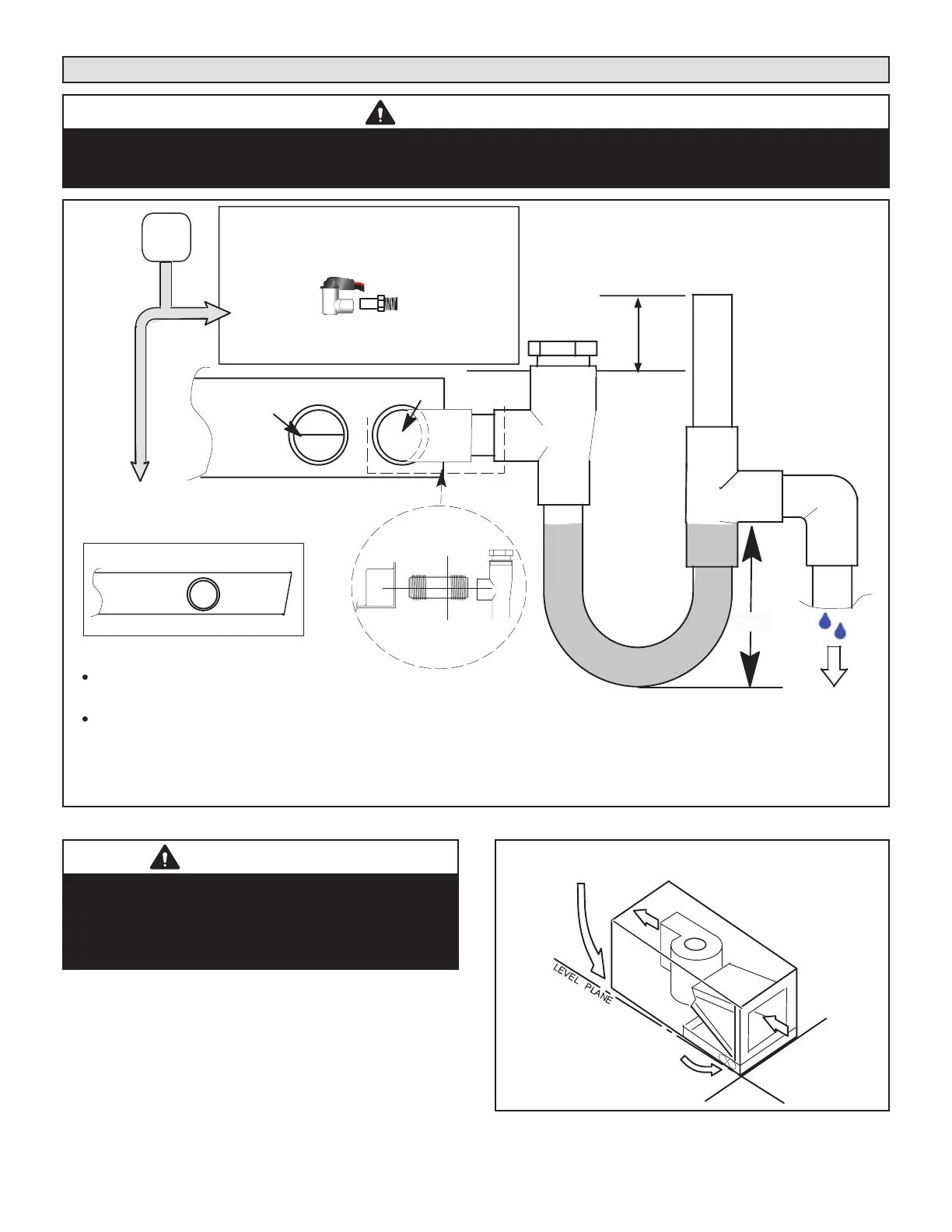

SEALING THE UNIT

Seal the unit so that warm air is not allowed into the cabi-

net. Warm air introduces moisture, which results in water

blow-o problems. This is especially important when the

unit is installed in an unconditioned area.

If installed in an unconditioned space, sealant should be

applied around the electrical wires, refrigerant tubing, and

condensate lines where they enter the cabinet.

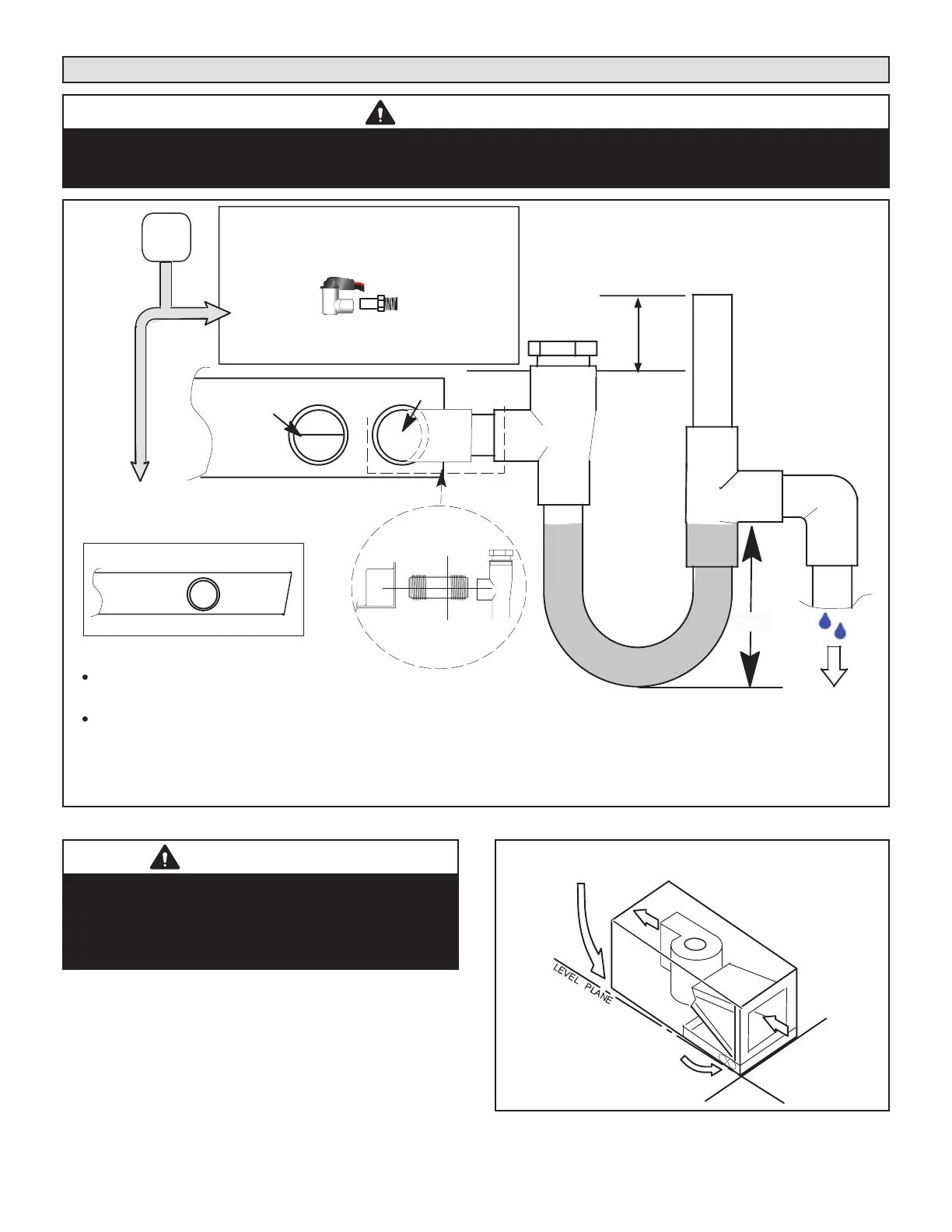

WARNING

There must be an airtight seal between the bottom of

the air handler and the return air plenum. Use berglass

sealing strips, caulking, or equivalent sealing method

between the plenum and the air handler cabinet to

ensure a tight seal. Return air must not be drawn from a

room where this air handler or any gas-fueled appliance

(i.e., water heater), or carbon monoxide-producing

device (i.e., wood replace) is installed.

Make sure the liquid line and suction line entry points are

sealed with either the provided exible elastomeric ther-

mal insulation, or eld provided material (e.g. Armaex,

Permagum or equivalent). Any of the previously men-

tioned materials may be used to seal around the main and

auxiliary drains, and around open areas of electrical inlets.

Electrical Connections

WARNING

Electric Shock Hazard. Can cause injury or

death. Unit must be properly grounded in

accordance with national and local codes.

Line voltage is present at all components when

unit is not in operation on units with single-

pole contactors. Disconnect all remote electric

power supplies before opening access panel.

Unit may have multiple power supplies.

WARNING

Electric Shock Hazard.

Can cause injury or death.

Foil-faced insulation has conductive characteristics

similar to metal. Be sure there are no electrical

connections within a ½” of the insulation. If the foil-faced

insulation comes in contact with electrical voltage, the

foil could provide a path for current to pass through to

the outer metal cabinet. While the current produced

may not be enough to trip existing electrical safety

devices (e.g. fuses or circuit breakers), the current can

be enough to cause an electric shock hazard that could

cause personal injury or death.

• All eld wiring must be done in accordance with Nation-

al Electrical Code, applicable requirements of UL and

local codes, where applicable.

• Electrical wiring, disconnect means and over-current

protection are to be supplied by the installer. Refer to

the air handler rating plate for maximum over-current

protection, minimum circuit ampacity, as well as oper-

ating voltage.

• The power supply must be sized and protected accord-

ing to the specications supplied on the product.

• This air handler is factory-congured for 240 volt, single

phase, 60 cycles. For 208-volt applications, see “208

Volt Conversion” later in this section.

• For optional eld-installed electric heat applications, re-

fer to the instructions provided with the accessory for

proper installation.

IMPORTANT

USE COPPER CONDUCTORS ONLY

1 - Disconnect all power supplies.

2 - Remove the air handler access panel.

3 - Route the eld supply wires to the air handler

electrical connection box.

4 - Use UL-listed wire nuts to connect the eld supply

conductors to the unit black and yellow leads, and

the ground wire to ground terminal marked GND.

5 - 5. Replace the air handler access panel.

CONNECT BLACK AND

YELLOW WIRES TO

FIELD-PROVIDED

CONDUCTORS.

CONNECT GROUND

WIRE TO GROUND

TERMINAL MARKED

FIGURE 25. Making Electrical Connections

Loading...

Loading...