SCROLL COMPRESSOR

DISCHARGE

SUCTION

FIGURE 11

FIGURE 12

Page 25

2-Scroll Compressor

All CHA/CHP16/20 (exĆ

cept the CHP16-024/030

units) model units utilize a

scroll compressor. The

scroll compressor design

is simple, efficient and reĆ

quires few moving parts. A

cutaway diagram of the

scroll compressor is

shown in figure 11. The

scrolls are located in the

top of the compressor can

and the motor is located in

the bottom of the compresĆ

sor can. The oil level is imĆ

mediately below the motor and oil is pressure fed to the movĆ

ing parts of the compressor. The lower portion of the comĆ

pressor shell is exposed to low side pressure while only the

very top of the shell is exposed to high side pressure.

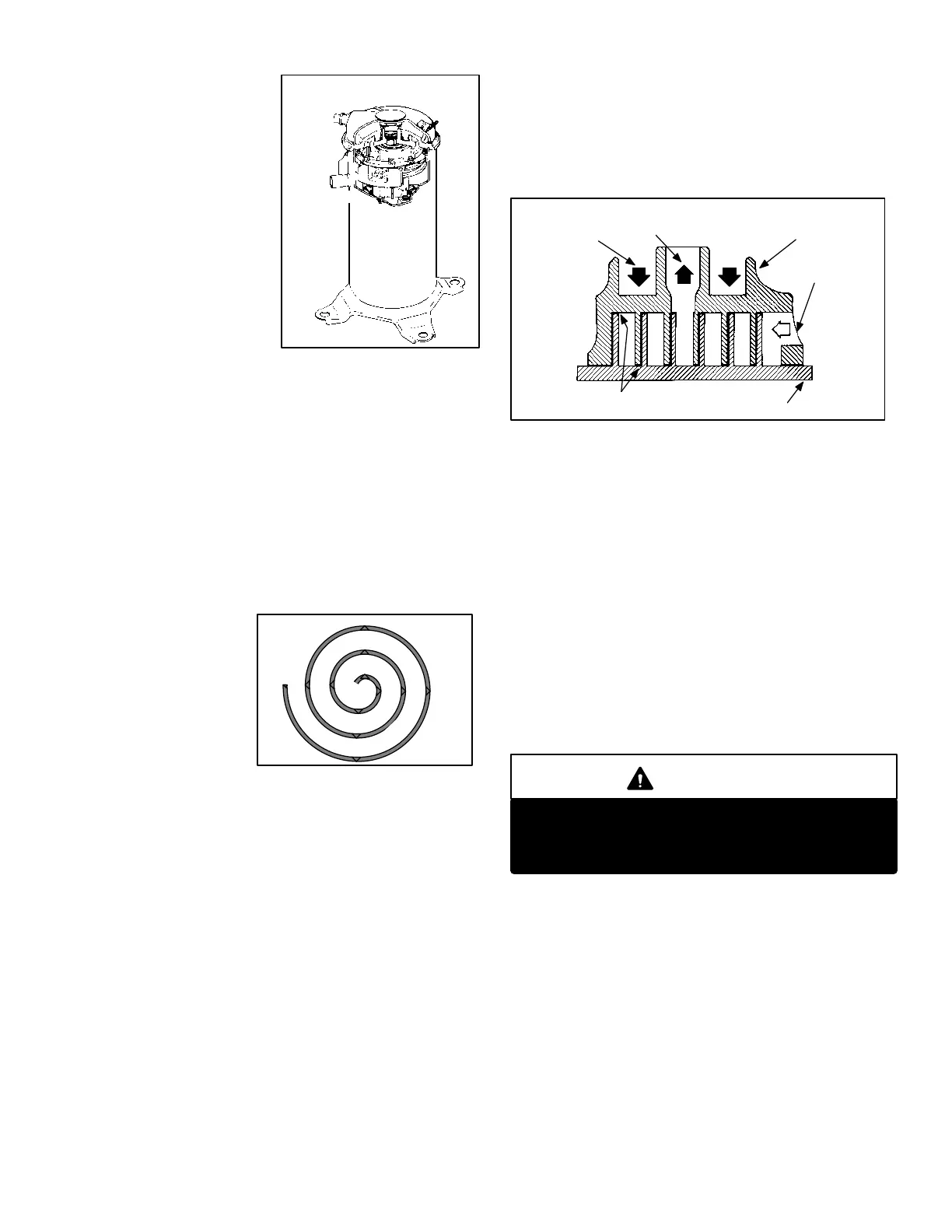

The scroll is a simple compression concept centered around

the unique spiral shape of the scroll and its inherent properĆ

ties. Figure 12 shows the basic scroll form. Two identical

scrolls are mated together forming concentric spiral shapes

(figure 13). One scroll reĆ

mains stationary, while

the other is allowed to orĆ

bit (figure 14-1). Note that

the orbiting scroll does

not rotate or turn but

merely orbits the stationĆ

ary scroll.

The counterclockwise orbiting scroll draws gas into the outĆ

er crescent shaped gas pocket created by the two scrolls

(figure 14-2). The centrifugal action of the orbiting scroll

seals off the flanks of the scrolls (figure 14-3). As the orbiting

motion continues, the gas is forced toward the center of the

scroll and the gas pocket becomes compressed (figure

14-4).

When compressed gas reaches the center, it is discharged

vertically into a chamber and discharge port in the top of the

compressor (figure11). The discharge pressure forcing

down on the top scroll helps seal off the upper and lower

edges (tips) of the scrolls (figure 13). During a single orbit,

several pockets of gas are compressed simultaneously proĆ

viding smooth continuous compression.

STATIONARY SCROLL

ORBITING SCROLL

DISCHARGE

SUCTION

CROSS-SECTION OF SCROLLS

TIPS SEALED BY

DISCHARGE PRESSURE

DISCHARGE

PRESSURE

FIGURE 13

The scroll compressor is tolerant to the effects of liquid reĆ

turn. If liquid enters the scrolls, the orbiting scroll is allowed

to separate from the stationary scroll. The liquid is worked

toward the center of the scroll and is discharged. If the comĆ

pressor is replaced, conventional Lennox cleanup practices

must be used.

Due to its efficiency, the scroll compressor is capable of

drawing a much deeper vacuum than reciprocating comĆ

pressors. Deep vacuum operation can cause internal fusite

arcing resulting in damaged internal parts and compressor

failure. It is permissible to pumpĆdown" the system using

the compressor but never use a scroll compressor for drawĆ

ing a vacuum on the system. This type of damage can be

detected and will result in denial of warranty claims.

CAUTION

The head of a scroll compressor may be hot since

it is in constant contact with discharge gas.

Contact could result in serious burns.

For compressor specifications see compressor nameplate

or ELECTRICAL DATA section in this manual. All compresĆ

sors are protected by internal overload protection circuitry.

Loading...

Loading...