Page 29

.

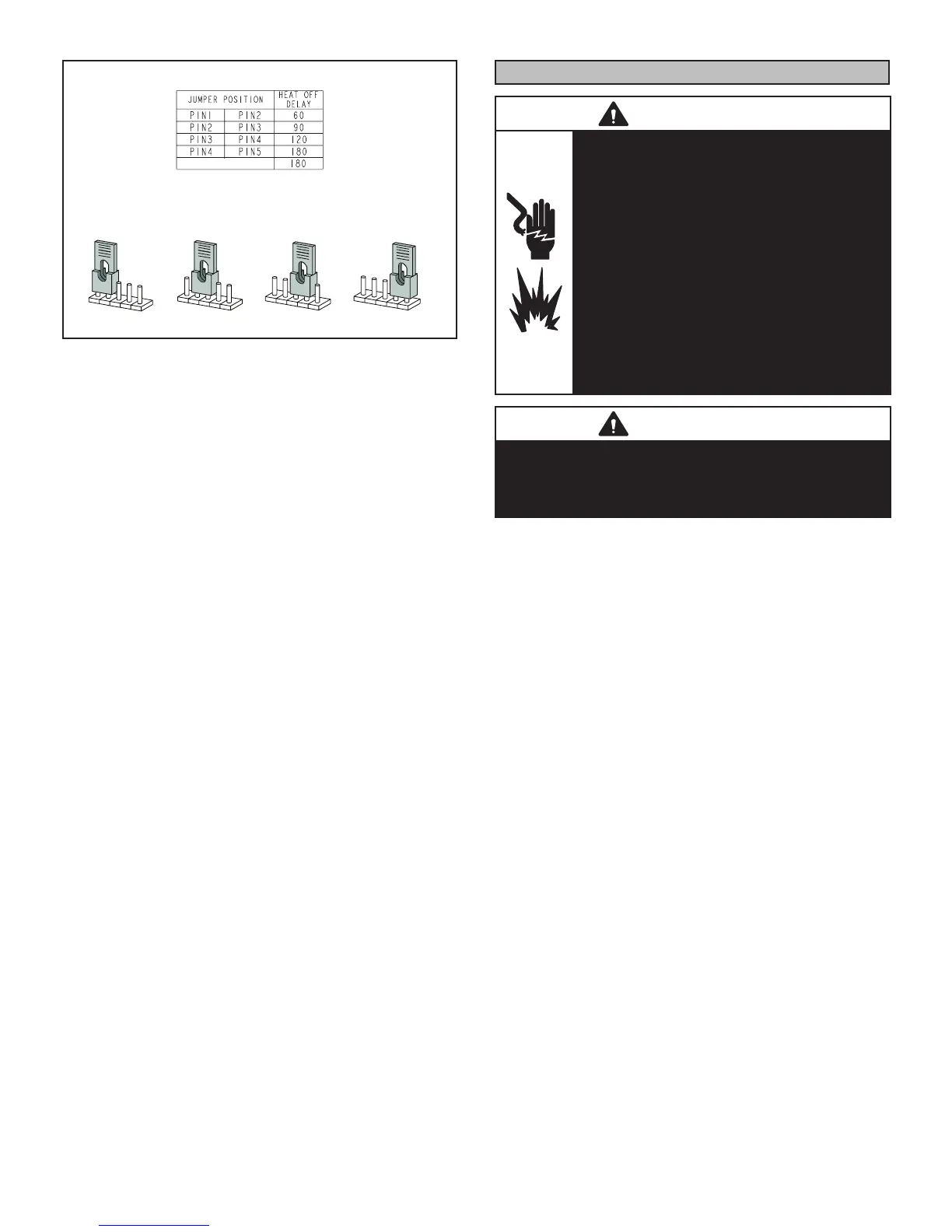

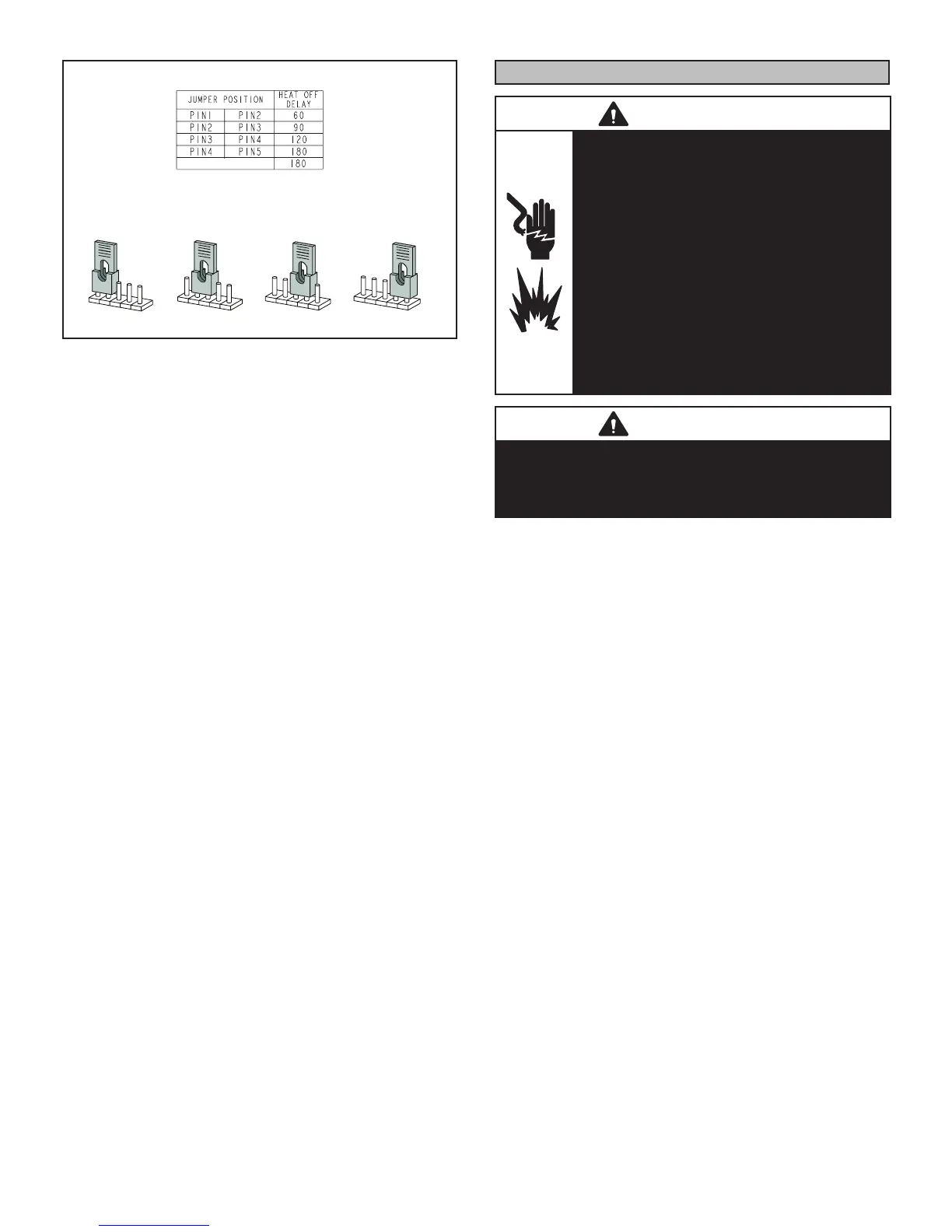

HEAT FAN‐OFF TIME IN SECONDS

To adjust fan-off timing, reposition jumper across pins to

achieve desired setting.

NO JUMPER

60

90

120

180

60

90

120

180

60

90

120

180

60

90

120

180

60 Second

off Time

90 Second

off Time

120 Second

off Time

180 Second

off Time

Figure 32

Constant Torque Motor

EL180UHE units are equipped with a constant torque ECM

motor. It has a DC motor coupled to an electronic control

module both contained in the same motor housing. The

motor is programmed to provide constant torque at each of

the ve selectable speeds. The motor has ve speed taps.

Each tap requires 24 volts to energize.

Input Voltage Requirements

The circuit is designed to be operated with AC voltage. A

voltage of 12 to 33VAC is required to energize the motor.

Expected current draw will be less than 20mA.

Blower Speeds

Follow the steps below to change the blower speeds.

1 - Turn off electrical power to furnace.

2 - Remove blower access panel.

3 - Disconnect existing speed tap at integrated control

speed terminal.

NOTE - Termination of any unused motor leads must be

insulated.

4 - Place unused blower speed tap on integrated

control “PARK” terminal or insulate.

5 - Refer to blower speed selection chart on unit wiring

diagram for desired heating or cooling speed.

See Product Specications manual for blower

performance data.

6 - Connect selected speed tap at integrated control

speed terminal.

7 - Resecure blower access panel.

8 - Turn on electrical power to furnace.

9 - Recheck temperature rise.

Electronic Ignition

The integrated control has an added feature of an internal

Watchguard control. The feature serves as an automatic

reset device for integrated control lockout caused by igni-

tion failure. This type of lockout is usually due to logas line

pressure. After one hour of continuous thermostat demand

for heat, the Watchguard will re-set and remake thermostat

demand to the furnace and automatically reset the integrat-

ed control to begin the ignition sequence.

Service

WARNING

ELECTRICAL SHOCK, FIRE,

OR EXPLOSION HAZARD.

Failure to follow safety warnings exactly

could result in dangerous operation, serious

injury, death or property damage.

Improper servicing could result in

dangerous operation, serious injury, death,

or property damage. Before servicing,

disconnect all electrical power to furnace.

When servicing controls, label all wires prior

to disconnecting.

Take care to reconnect wires correctly.

Verify proper operation after servicing.

WARNING

The blower door must be securely in place when the

blower and burners are operating. Gas fumes, which

could contain carbon monoxide, can be drawn into the

living space resulting in personal injury or death.

Annual Furnace Maintenance

At the beginning of each heating season, and to comply

with the Lennox Limited Warranty, your system should be

checked by a licensed professional technician (or equiva-

lent) as follows:

1 - Check wiring for loose connections, voltage at

indoor unit and amperage of indoor motor.

2 - Check the condition of the belt and shaft bearings

if applicable.

3 - Inspect all gas pipe and connections for leaks.

4 - Check the cleanliness of lters and change if

necessary (monthly).

5 - Check the condition and cleanliness of burners and

heat exchanger and clean if necessary.

6 - Check the cleanliness of blower assembly and

clean the housing, blower wheel and blower motor

if necessary . The blower motors are prelubricated

for extended bearing life. No further lubrication is

needed.

7 - IInspect the combustion air inducer and clean if

necessary.

8 - Evaluate the heat exchanger integrity by inspecting

the heat exchanger per the AHRI heat exchanger

inspection procedure. This procedure can be

viewed at www.ahrinet.org

Loading...

Loading...