Page 67

VII- Wiring and Sequence of Operation

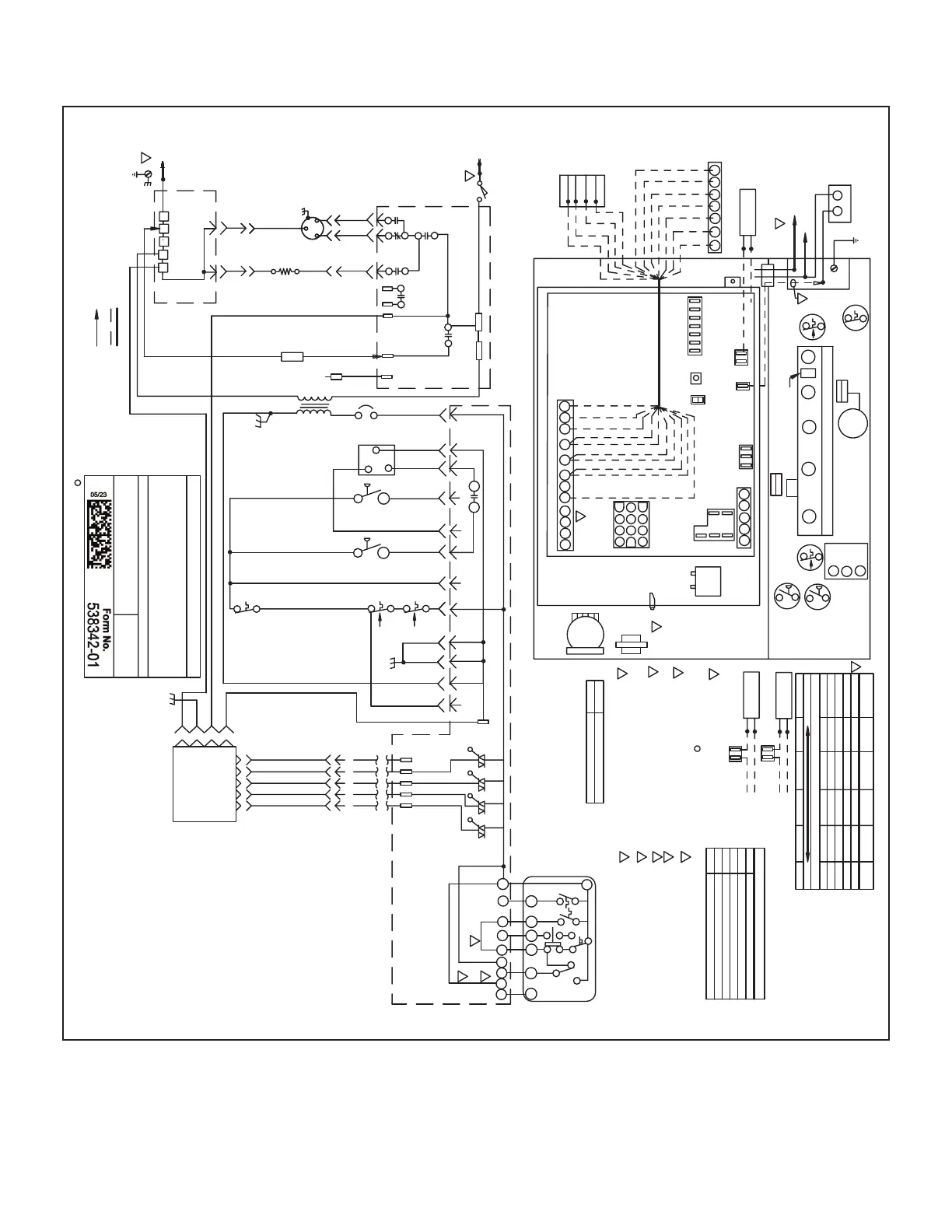

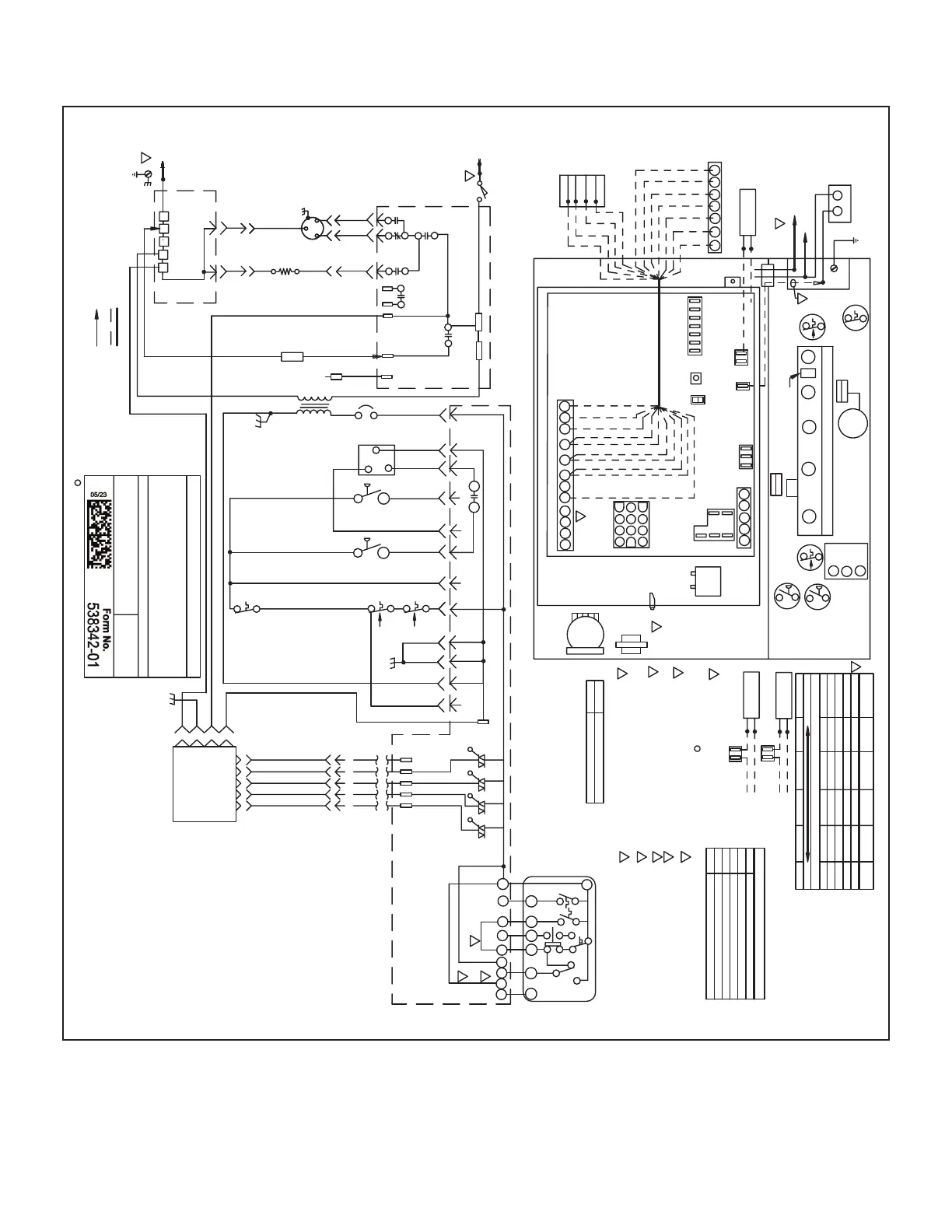

EL297DFV WITH IGNITION CONTROL 107045-XX UNIT DIAGRAM

J159

P159

IGNITOR

1

2

NOTE-

IF ANY WIRE IN THIS APPLIANCE IS REPLACED,IT

MUST BE REPLACED WITH WIRE OF LIKE SIZE,

HEATING UNITS-GAS

S51

L1

N

N N N

EQUIPMENT

GROUND

N N

P159

J159

BLUE

BLUE

CB8

WARNING-

ELECTRIC SHOCK HAZARD,CAN CAUSE INJURY

OR DEATH.UNIT MUST BE GROUNDED IN ACCORDANCE

WITH NATIONAL AND LOCAL CODES.

DENOTES OPTIONAL COMPONENTS

LINE VOLTAGE FIELD INSTALLED

CLASS II VOLTAGE FIELD WIRING

.65 AMP

24V

24VAC

SEC

NO

S102

C

GV1

GAS

VALVE

R33

S10

INTEGRATED

CONTROL

A92

THERMOSTAT HEAT ANTICIPATION SETTING

INTEGRATED CONTROL

INTEGRATED

CONTROL

A92

LOW HEAT

PRESSURE

SWITCH

CB8

S102

HIGH HEAT

PRESSURE

SWITCH

W2

PRIMARY

GAS

LIMIT

CIRCUIT

BREAKER

T1

TRANSFORMER

120V ACC

(IF USED)

G

N

L1

GV1

GAS

VALVE

B3

S51

S1

ROOM THERMOSTAT

C

Y1

OUTDOOR

UNIT

Y1

G

W1

R

C

9

8

7

6

5

4

3

21

C

HI

S10

S128

COMBUSTION AIR

INDUCER MOTOR

B6

P84

J84

INTERLOCK

DOOR

L13

POWER

CHOKE

P48

P49

24VAC

COM

Y2

W2

W1

G

Y1

R

DS

3

2

TERMINAL BOARD

Y2

INDOOR

BLOWER

MOTOR

Y2

Supersedes

Litho U.S.A.

C

MVL

7

11

5

12

HLI

RO(OUT)

6

8

TH

GND

TR

MV COM

FLAME

SENSOR

A92

FLAME

SENSE

2

3

1

HUM

4

WHT

120V

T1

BLK

B6

J84

J84

COMBUSTION AIR

BLOWER MOTOR

3

COMBUSTION AIR

BLOWER MOTOR

P84

P84

B6

2

DOOR

INTERLOCK

5

LINE

CIRC

2

HIGH HEAT

PRESSURE SWITCH

1

LOW HEAT

PRESSURE SWITCH

S128

PS2

MVH

PS1

C

4

10

9

GND

HOT

O

W951

S1

C

NO

9

4

11

(1) S47

2 HEAT 2 COOL

S47

J159

P159

FLAME

ROLLOUT

SWITCH

10

11

12

TB1

HONEYWELL VALVE

1

4

4

BURNERS

R33

IGNITOR

FLAME

SENSOR

5

6

7

FIELD SUPPLIED ACC WIRE

6

1

HEAT

COOL

FAN

ON

R

W1

Y1

G

W2

Y2

COOL

2

2

AUTO

ROOM THERMOSTAT

TWO STAGE

HEAT,COOL

USE COPPER CONDUCTORS ONLY

7

LENNOX

W1

W2

G

Y2

Y1

C

LO

DS

3

RO(IN)

L

HEAT PUMP

CUT W951 JUMPER FROM O TO R, LABELED

"HEAT PUMP", AT A92 CONTROL BOARD, WHEN

USED FOR DUAL FUEL APPLICATIONS

RATING, INSULATION THICKNESS, AND TERMINATION

K1

K4

K7

K8

8

8

HI

W914

W915

2

3

1

.43 AMP

WHITE RODGERS VALVE

CUT W914 JUMPER LABELED DEHUM FROM DS

TO R, AT A92 CONTROL BOARD, WHEN USED

WITH ComfortSense

7000 THERMOSTAT

R

NOTE: SEE INSTALLATION INSTRUCTIONS FOR PROCEDURE

TO SET CORRECT BLOWER SPEED FOR SPECIFIC COOLING

TONNAGE BEING APPLIED, AND HEATING TEMPERATURE

RISE REQUIRED.

TYPICAL SYSTEM SHOWN FOR 2 HEAT/2 COOL WITH A

CONVENTIONAL THERMOSTAT. SEE INSTALLATION

INSTRUCTIONS FOR CONNECTIONS TO OTHER EQUIPMENT

AND ACCESSORIES.

DIP SWITCH FACTORY DEFAULT IS FOR A TWO

STAGE THERMOSTAT

DH AND L TERMINALS NOT USED.

M

1

2

3 4

5

6

7

J3

L1

NEUTRALS

J2

M

7

7

2011

C

R

DH

HUM

ACC

L1

J3

P3

J3

P3

P3

J3

P3

J3

120V

ACC

ACC

DIAGNOSTIC

PUSH

BUTTON

C

C

SEVEN

SEGMENT

LED

K5

K11

SEE HUM VIEWS

HUMIDIFIER

HUMIDIFIER

HUMIDIFIER

HUM

AT IFC

TO C

TO R OR H ON CS7000

TO N

TO L1

HUM

AT IFC

P2

J2

EL297DF045XE36B

EL297DF070XE48B

(2) S47

S47

FLAME

ROLLOUT

SWITCH

JACK/PLUG-INDOOR BLOWER-POWER

J,P48

J,P49

J,P2

J,P84

L13 USED ON 3/4

AND 1 HP ONLY

EL297DF090XE48C

EL297DF110XE60C

WHT

WHT

WHT

WHT/PINK

YEL

ORG

PURPLE

BRW

PINK

BRW

STRIPE

BLUE

PINK

BLUE

PURPLE

BRW

GRN/YEL

GRN/YEL

YEL

BRW

YEL

BLK

RED

WHT

9

DO NOT USE RED (LOW SPEED) FOR HIGH

HEAT ON ALL MODELS.

J49

BLUE

YLW

BRN

BLK

4

3

2

1

5

PARK

LOW HEAT

HIGH HEAT

LOW COOL

HIGH COOL

SEE BLOWER SPEED CHART

RED

UNIT

HIGH HEAT

HI COOL LOW COOL

BLACK

BLUE

DF045XE36B

DF070XE48B

DF090XE48C

DF110XE60C

HI

SPEED TAPS

LOW HEAT PARK

LOW

BLACK

BLACK

BLACK

YELLOW

YELLOW

YELLOW

YELLOW

RED

RED

RED

RED

YELLOW

RED

BROWN

BROWN

BROWN

BLUE

BLUE

BLUE

BLACK

BLUE

BROWN

BLOWER SPEED SELECTION

BROWN

JACKPLUG CHART

J,P3

J,P159

JACK/PLUG-INDOOR BLOWER-SPD TAP

JACK/PLUG-BURNER CONTROL

JACK/PLUG-COMB AIR INDUCER

JACK/PLUG-INDUCER/IGNITER

JACK/PLUG-IGNITION

9

J48

P48

INDOOR

BLOWER

MOTOR

C

L

G

N

WHT/BLK

BLACK

GN/YLW

WHT

B3

24-V

COM.

P49

4

3

2

1

5

CUT W915 JUMPER LABELED "2 STAGE COMPR."

FROM Y1 TO Y2 AT A92 CONTROL WHEN USED

WITH A 2 STAGE COOL THERMOSTAT.

BRN W / YEL

CUT SIZE 9" WIDE x 8-1/4" TALL

Loading...

Loading...