Do you have a question about the Lennox Elite EL17XC1 Series and is the answer not in the manual?

| Compressor Type | Single-Stage |

|---|---|

| Refrigerant | R-410A |

| Energy Star Certified | Yes |

| SEER Rating | 17.00 |

| Warranty | 10-Year Limited Warranty on covered components |

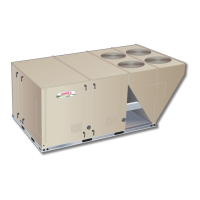

Table listing dimensions for various EL17XC1 models in inches and millimeters.

Instructions for mounting the unit on an elevated slab using feet extenders.

Guidance on securing the unit on uneven or unstable surfaces.

Procedures for installing the unit on a concrete slab.

Instructions for flushing existing refrigerant lines and indoor coils before installation.

Table detailing recommended refrigerant line set sizes based on model and length.

Procedure for removing a fixed orifice metering device from the indoor coil.

Procedure for removing an existing expansion valve from the indoor coil.

Instructions on preparing refrigerant lines for brazing, including cutting and deburring.

Steps for removing service valve caps and cores before brazing.

Guidance on connecting a manifold gauge set for brazing operations.

How to wrap service valves with water-saturated cloths to protect them during brazing.

Procedure for flowing nitrogen through the system during brazing for protection.

Instructions for brazing the refrigerant line set to the service valves.

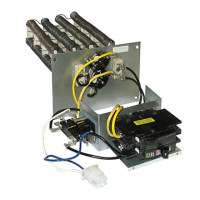

Detailed steps for installing the expansion valve unit at the indoor coil.

Guidance on correctly installing the sensing bulb for the expansion valve.

Instructions for connecting the equalizer line to the expansion valve assembly.

Procedure for connecting the manifold gauge set for leak testing with HFC-410A.

Steps to test the system for leaks using HFC-410A and nitrogen.

Connecting the gauge set, micron gauge, and vacuum pump for system evacuation.

Detailed procedure for evacuating the refrigerant lines and indoor unit to a specific micron level.

Guidance on sizing electrical circuits and installing the disconnect switch.

Instructions for installing the room thermostat at the correct location.

Essential checks to perform before starting the unit for the first time.

How to operate and use manifold gauge sets and service valves.

Table listing recommended torque values for various fasteners.

Table for calculating additional refrigerant charge based on line set length.

List of inspection and maintenance tasks for the outdoor unit.

List of inspection and maintenance tasks for the indoor unit.

Procedures for performing a general system test with the unit operating.

Checklist items for verifying performance during cooling mode operation.

Loading...

Loading...