Page 9

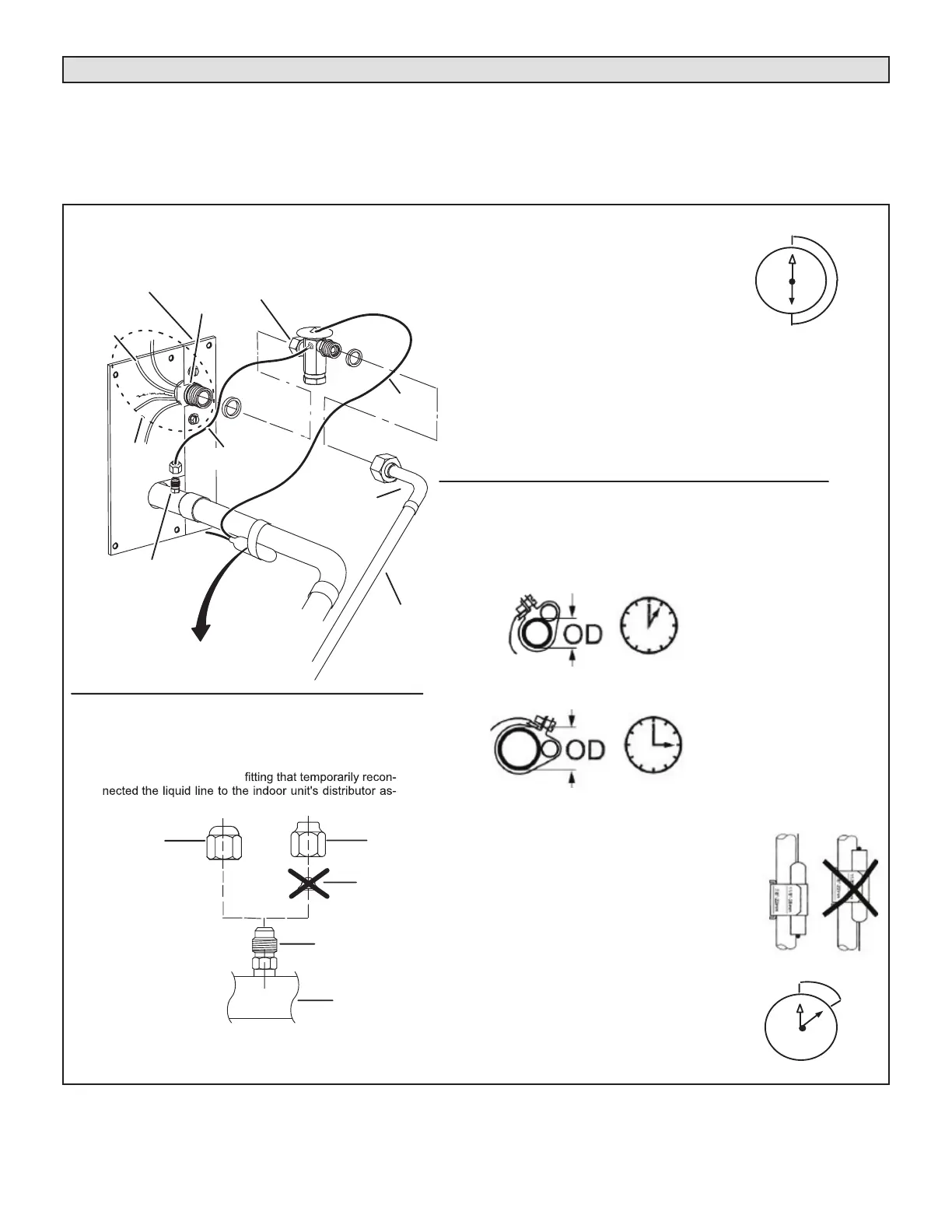

REFRIGERANT PIPING – Install Indoor Expansion Valve

This outdoor unit is designed for use in systems that include an expansion valve metering device (purchased separately)

at the indoor coil. See the EL22XPV Product Specications bulletin (EHB) for approved expansion valve kit match-ups

and application information. The expansion valve unit can be installed internal or external to the indoor coil. In applica-

tions where an uncased coil is being installed in a eld-provided plenum, install the expansion valve in a manner that will

provide access for future eld service of the expansion valve. Refer to below illustration for reference during installation

of expansion valve unit.

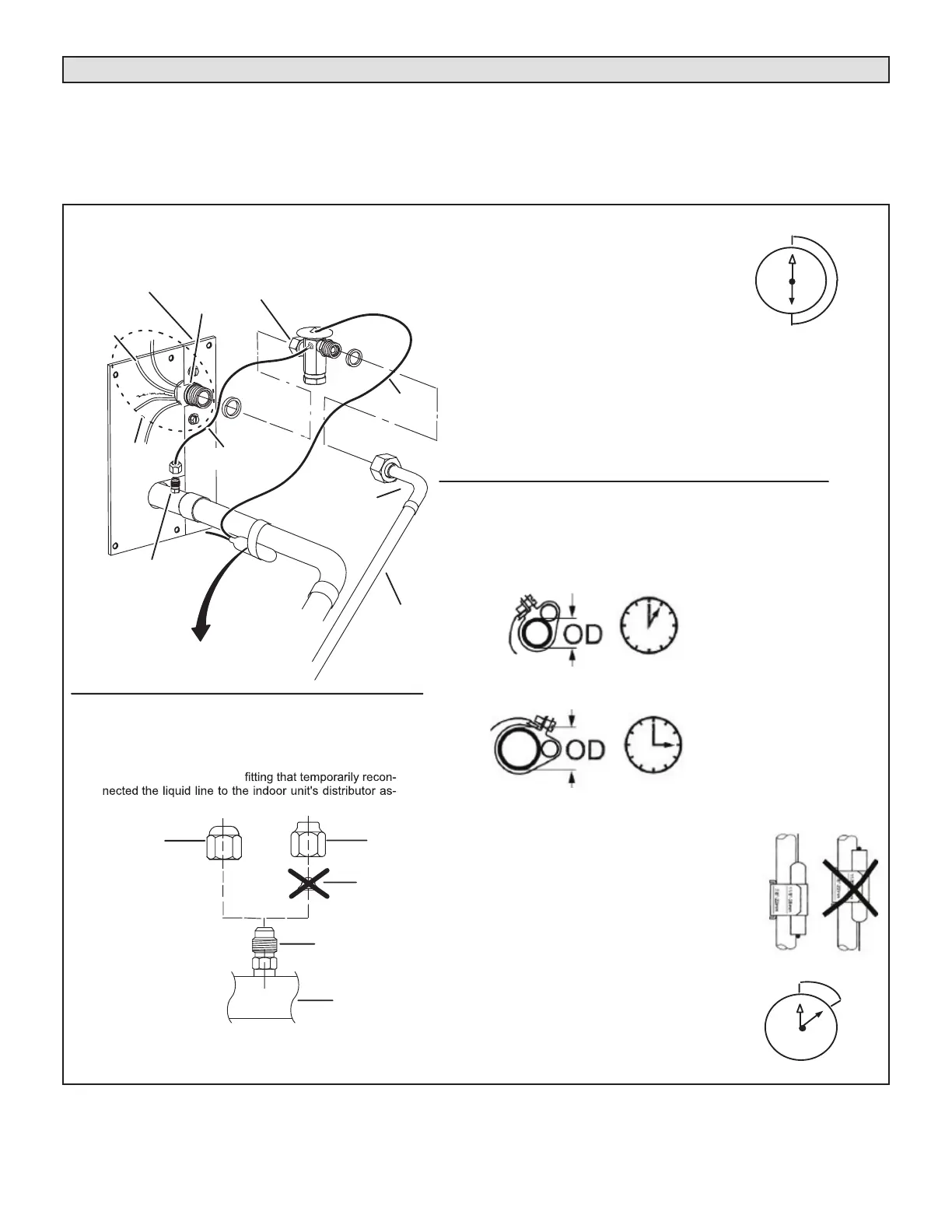

1 - Attach the vapor line sensing bulb in the proper

orientation as illustrated belowusing

provided.

NOTE - Though it is preferred to have the sensing bulb

installed on ahorizontal run of the vapor line, installation

on a vertical run of piping is acceptable if necessary.

See figure to right for proper bulb orientation on vert-

ical run of piping.

NOTE - Confirm proper thermal contact between vapor

line and check/expansion bulb before insulating the

sensing bulb once installed.

the equalizer vapor port on the vapor line. Finger

the flare nut plus 1/8 turn (7 ft-lbs) as illustrated

2 - Connect the equalizer line from the check expansion

valve to

tighten

to the right.

TWO PIECE

PATCH PLATE

(UNCASED

COIL ONLY)

VAPOR

LINE

LIQUID LINE

ORIFICE

HOUSING

DISTRIBUTOR

TUBES

LIQUID LINE

MALE EQUALIZER LINE

FITTING (SEE

EQUALIZER LINE

INSTALLATION FOR

FURTHERDETAILS)

SENSING

LINE

EQUALIZER

LINE

CHECK

EXPANSION

VALVE

TEFLON

®

RING

(Uncased Coil Shown)

Sensing bulb insulation is required if

mountedexternal to the coil casing. sensing

bulb installation for bulb positioning.

STUB

END

TEFLON

®

RING

LIQUID LINE

ASSEMBLY WITH

BRASS NUT

DISTRIBUTOR

ASSEMBLY

3 - Install one of the provided Teflon

®

rings around the

stubbed endofthe check expansion valve and lightly

lubricate the connector threads andexpose surface of

the Teflon

®

ring with refrigerant oil.

4 - Attachthe stubbed end of the check expansion valve to

the liquid line orifice housing.Finger tighten and use an

appropriatelysized wrench to turn an additional 1/2 turn

clockwise as illustrated in the figure above, or tighten to

20 ft-lb.

5 - Place the remaining Te flon

®

washer around theother

end of the check expansion valve. Lightly lubricate

connector threads and expose surface of the Teflon

®

ring with refrigerant oil.

6 - Attachthe liquid line assembly to the check expansion

valve.Fingertighten and use an appropriately sized

wrenchto turn an additional 1/2 turn clockwise as

illustrated in the figure above or tighten to 20 ft-lb.

ON 3/4" ANDLARGERLINES, MOUNT SENSING BULB AT

EITHER THE 3 OR 9 O’CLOCK POSITION.

NOTE - NEVER MOUNT THE SENSING BULB ON

BOTTOM OF LINE.

VAPOR LINE

FLARENUT

COPPER FLARE

SEAL BONNET

MALE BRASS EQUALIZER

LINE FITTING

FLARE SEAL CAP

OR

1

2

3

4

5

6

7

8

9

10

11

12

1/2 Turn

SENSING BULB INSTALLATION

EQUALIZER LINE INSTALLATION

1

2

3

4

5

6

7

8

9

10

11

12

1/8Turn

1 - Remove and discard either the flare seal cap or flare nut

with copper flare seal bonnet from the equalizer line port

on the vapor line as illustrated in the figure below.

2 - Remove thefield-provided

sembly.

INDOOR EXPANSION VALVE INSTALLATION

the clamp and screws

ON LINES SMALLER THAN 3/4", MOUNT SENSING BULB AT

EITHER THE 1 OR 11 O’CLOCK POSITION.

FIGURE 8

Loading...

Loading...