GAS FLAPPER VALVE

REQUIRED CLEARANCE

VALVE BODY

FLAPPER

ORING

REQUIRED CLEARANCE

0.024" + 0.003"

FIGURE 74

Page 53

TABLE 17

AIR FLAPPER VALVE CLEARANCES (In.)

Unit Natural L.P.G.

G2160

G2140

G2180

G21100

GSR2150

GSR2180

GSR21100

.031

.035

.0425 or .045

.037

.035

.0425 or .045

.039

.035

.0425 or .045

.040

.035

.0425 or .045

.037

.039

G21Q100−5,−6,−7,−8

.040 .040

G21V−7,−8

.040 .040

6 − When placing a new or old valve back into the unit, start

all eight screws in place by hand. Tighten screws even

ly to a maximum of 15 in./lbs. Do not overtighten

screws; if threads are damaged the entire valve body

will have to be replaced. All eight screws must be in

place for proper operation

CLEARANCES ARE SUBJECT TO CHANGE. REFER TO LENNOX

REPAIR PARTS OR SERVICE AND APPLICATION NOTES HEATING

TAB FOR LATEST INFORMATION.

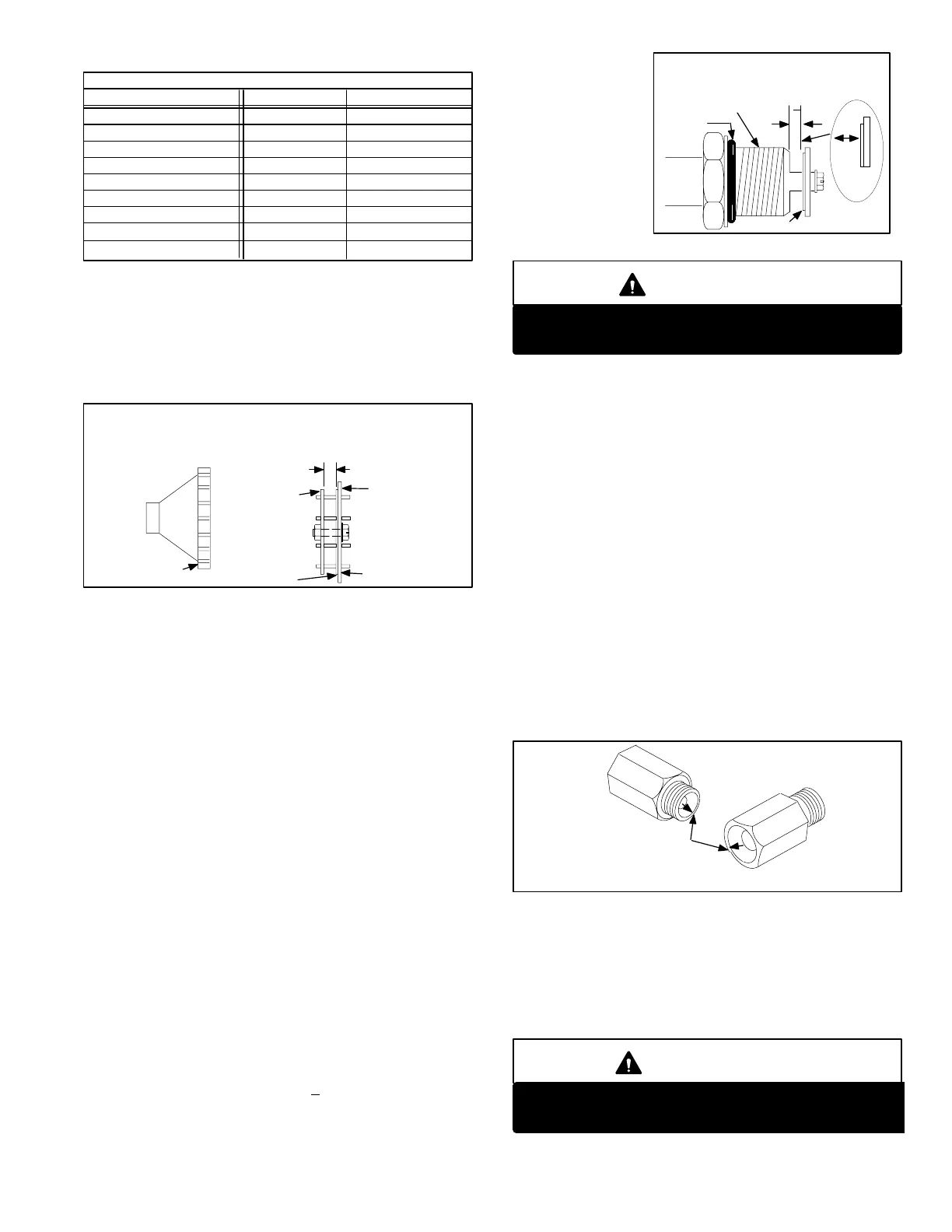

COVER

PLATE

VALVE BODY

BACK

PLATE

FLAPPER

STAMP

40,50, 60, 80 AIR FLAPPER VALVE CLEARANCE

CLEARANCE

FIGURE 73

O − Checking the Gas Flapper Valve

1 − Using a plumber’s basin wrench, disconnect union at

bottom of expansion tank and remove entire gas flap

per valve, nipple and elbow assembly as one piece. It

is not recommended to remove elbow and nipple from

flapper unless the valve is being replaced. Use care

not to damage oring when handling valve out of unit.

DO NOT DROP.

2 − Do not turn or remove center screw of valve assembly.

Visually inspect the flapper. The flapper may be dished

or curved on new units, this is normal. In units with run

in" time, the flapper will be flat. If the flapper is torn,

creased or has uneven (frayed) edges, the valve as

sembly must be replaced.

3 − Check for free movement of the flapper over the

spacer. Use a feeler gauge blade to carefully move the

flapper between the plates. Be sure the flapper is not

trapped between the spacer and the other clearance

plate. If the flapper does not move freely or is trapped

under the spacer, the valve assembly must be re

placed.

4 − Check for the required clearance between the flapper

and valve body. Required clearance values for

G21/GSR21 units are 0.024 + 0.003 in. Use a feeler

gauge, starting small and working up to the clearance di

mensions until the gauge is just about snug. Do not force

gauge. Check

clearance around

the valve in sev

eral places. If the

valve is out of the

required clear

ance dimension

given in figure at

any point around

the valve, it must

be replaced.

Do not force feeler gauge between flapper and

valve body. Damage to flapper material will occur.

WARNING

5 − When placing a new or old valve back into the unit, use

care not to damage the oring. DO NOT USE PIPE SEAL

ERS ON THE FLAPPER VALVE THREADS.

P − Checking Gas Orifice

1 − With gas flapper valve assembly removed, use a flash

light to check for blockage of the orifice in the manifold.

To remove the orifice, most units use a 1/2 inch shallow

socket with an extension.

2 − Check the orifice drill size for the unit as given in the

Service and Application notes. Make sure orifice diam

eter matches the drill size stamped on the orifice. If the

orifice is incorrect it must be replaced.

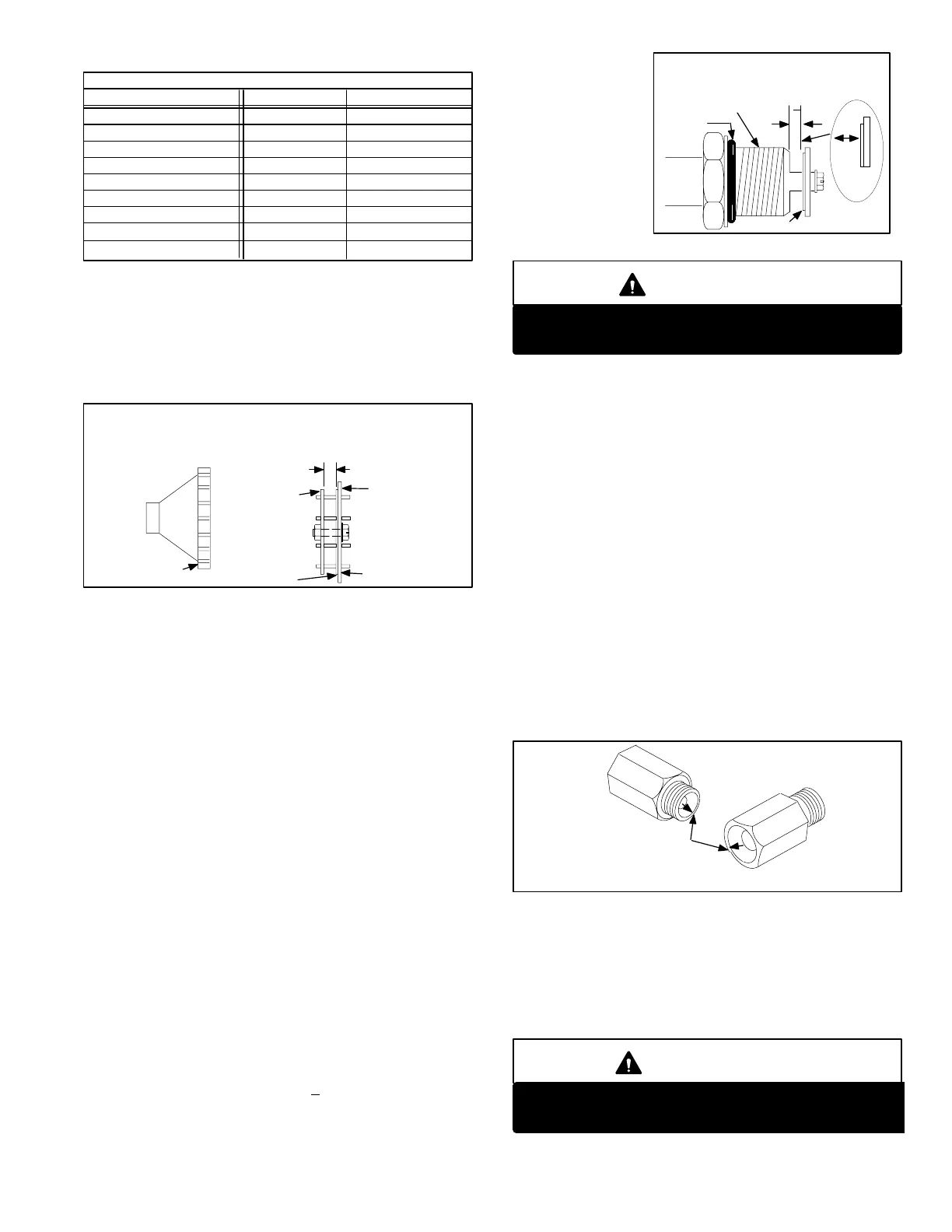

3 − Refer to figure for the physical characteristics of the ori

fice. The surface must be flat and the orifice opening

must not be chamfered. The orifice taper must be cen

tered and not recessed. G21/GSR21 units use a

doubleconed orifice to improve operating characteris

tics. If any defects are found the orifice must be re

placed.

G21/GSR21 SERIES ORIFICE

CHARACTERISTICS

ORIFICE MUST BE TAPERED ON BOTH SIDES

ORIFICE TAPER MUST BE CEN

TERED. RIDGE MUST BE EQUAL

AROUND PERIMETER AND TA

PER MUST START AT LEADING

EDGE (NOT RECESSED)

FIGURE 75

4 − Standard atmospheric burner orifices or orifice blanks

cannot be used as replacements for the G21/ GSR21.

Only replacement orifices supplied through Lennox

should be used.

5 − When threading the orifice into the manifold use a sock

et to hold threads beyond end of socket.

IMPORTANT

To avoid cross threading, carefully align threads by

hand turning socket extension until orifice is in place.

Loading...

Loading...