Page 17

FIGURE 15

MANUAL MAIN SHUT-OFF

VALVE WILL NOT

HOLD NORMAL

TEST PRESSURE

CAP

FURNACE

ISOLATE

GAS

VALVE

CAP

The furnace must be isolated from the gas supply system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply system at pressures

equal to or greater than 1/2 psig (3.48 kPa).

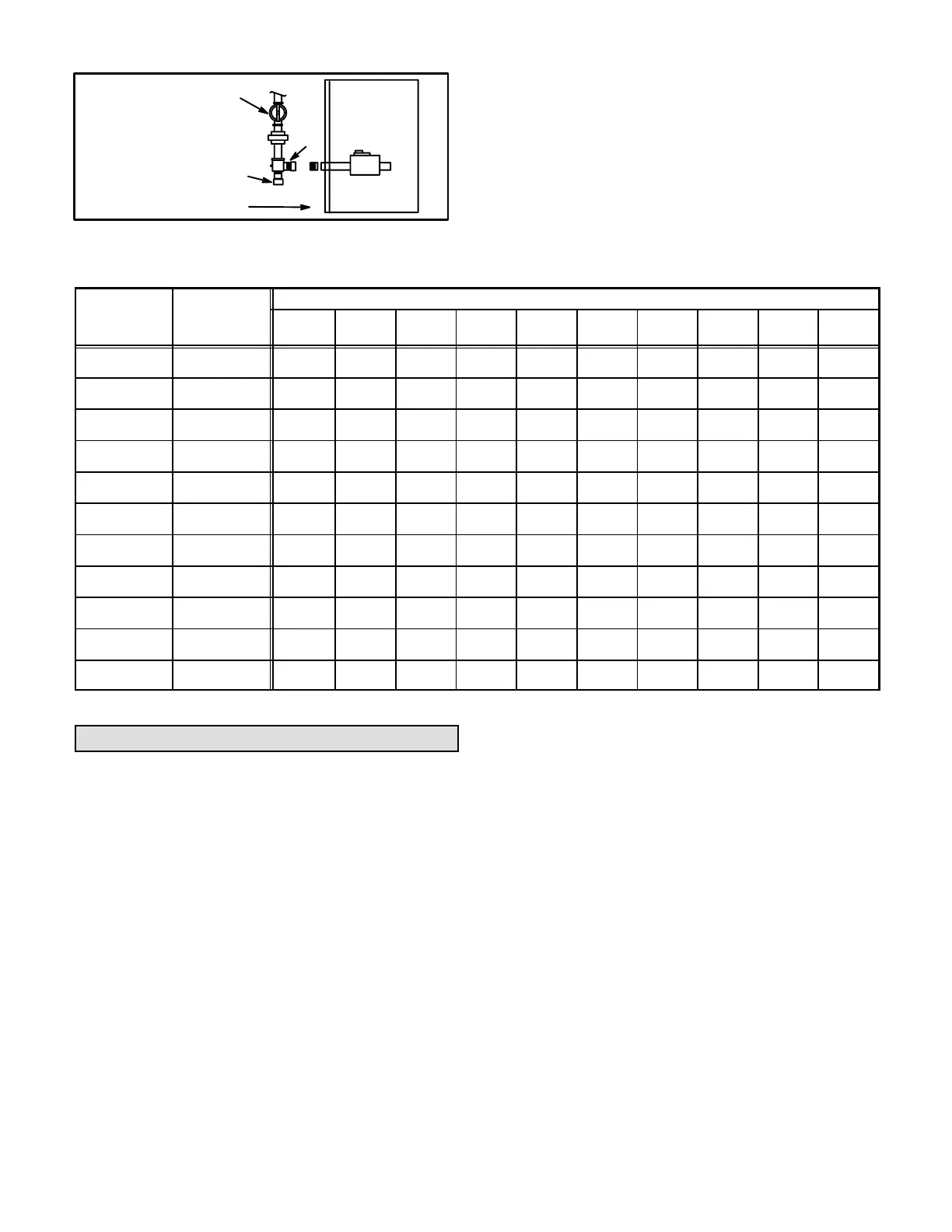

TABLE 9

GAS PIPE CAPACITY - FT

3

/HR (kL/HR)

Nominal Internal

Length of Pipe-Feet(m)

Iron Pipe Size

-Inches(mm)

Diameter

-Inches(mm)

10

(3.048)

20

(6.096)

30

(9.144)

40

(12.192)

50

(15.240)

60

(18.288)

70

(21.336)

80

(24.384)

90

(27.432)

100

(30.480)

1/4

(6.35)

.364

(9.246)

43

(1.13)

29

(.82)

24

(.68)

20

(.57)

18

(.51)

16

(.45)

15

(.42)

14

(.40)

13

(.37)

12

(.34)

3/8

(9.53)

.493

(12.522)

95

(2.69)

65

(1.84)

52

(1.47)

45

(1.27)

40

(1.13)

36

(1.02)

33

(.73)

31

(.88)

29

(.82)

27

(.76)

1/2

(12.7)

.622

(17.799)

175

(4.96)

120

(3.40)

97

(2.75)

82

(2.32)

73

(2.07)

66

(1.87)

61

(1.73)

57

(1.61)

53

(1.50)

50

(1.42)

3/4

(19.05)

.824

(20.930)

360

(10.19)

250

(7.08)

200

(5.66)

170

(4.81)

151

(4.28)

138

(3.91)

125

(3.54)

118

(3.34)

110

(3.11)

103

(2.92)

1

(25.4)

1.049

(26.645)

680

919.25)

465

(13.17)

375

(10.62)

320

(9.06)

285

(8.07)

260

(7.36)

240

(6.80)

220

(6.23)

205

(5.80)

195

(5.52)

1-1/4

(31.75)

1.380

(35.052)

1400

(39.64)

950

(26.90)

770

(21.80)

660

(18.69)

580

(16.42)

530

(15.01)

490

(13.87)

460

(13.03)

430

(12.18)

400

(11.33)

1-1/2

(38.1)

1.610

(40.894)

2100

(59.46)

460

(41.34)

1180

(33.41)

990

(28.03)

900

(25.48)

810

(22.94)

750

(21.24)

690

(19.54)

650

(18.41)

620

(17.56)

2

(50.8)

2.067

(52.502)

3950

(111.85)

2750

(77.87)

2200

(62.30)

1900

(53.80)

1680

(47.57)

1520

(43.04)

1400

(39.64)

1300

(36.81)

1220

(34.55)

1150

(32.56)

2-1/2

(63.5)

2.469

(67.713)

6300

(178.39)

4350

(123.17)

3520

(99.67)

3000

(84.95

2650

(75.04)

2400

(67.96)

2250

(63.71)

2050

(58.05)

1950

(55.22)

1850

(52.38)

3

(76.2)

3.068

(77.927)

11000

(311.48)

7700

(218.03)

6250

(176.98)

5300

(150.07)

4750

(134.50)

4300

(121.76)

3900

(110.43)

3700

(104.77)

3450

(97.69)

3250

(92.03)

4

(101.6)

4.026

(102.260)

23000

(651.27)

15800

(447.39)

12800

(362.44)

10900

(308.64)

9700

(274.67)

8800

(249.18)

8100

(229.36)

7500

(212.37)

7200

(203.88)

6700

(189.72)

NOTE-Capacity given in cubic feet of gas per hour (kilo liters of gas per hour) and based on 0.60 specific gravity gas.

Electrical

A field makeup box is provided for line voltage wiring.

Line voltage wiring to unit is done through the J69 jack

from the field makeup box to plug P69 from the control

box. See figures 17 and 18 for makeup box installation.

Figure 19 shows thermostat designations for identifica

tion purposes. Refer to figure 20 for control box arrange

ment, 21 for a detail of the SureLight integrated control

board (SureLight control), figure 22 for schematic wiring

diagram and troubleshooting, and figure 23 for point to

point field wiring.

1 - Install field makeup box on either side, inside or out

of the cabinet. Wiring knockouts are provided in box

and cabinet. See figures 17 and 18.

2 - Remove cap from knockout in blower deck on the

same side as the installed makeup box.

3 - Electrically ground unit in accordance with local

codes or, in the absence of local codes, in accor

dance with the current National Electric Code (ANSI/

NFPA No. 70). The green ground wire is provided in

the field make-up box.

To ensure proper grounding of the furnace, two star

washers are included in the electrical makeup box

bag assembly. Place the star washer on securing

screw before installing the makeup box. Make sure

the star washer breaks the paint on the cabinet so

that the washer is touching metal. Unit is not properly

grounded if paint has not been removed by star

washer.

Loading...

Loading...