Page 25

Charge Verification - Approach Method - AHRI Testing

(Fin/Tube Coil Continued)

1. Using the same thermometer, compare liquid

temperature to outdoor ambient temperature.

Approach Temperature = Liquid temperature (at

condenser outlet) minus ambient temperature.

2. Approach temperature should match values in table

15. An approach temperature greater than value

shown indicates an undercharge. An approach

temperature less than value shown indicates an

overcharge.

3. The approach method is not valid for grossly over or

undercharged systems. Use table 14 as a guide for

typical operating pressures.

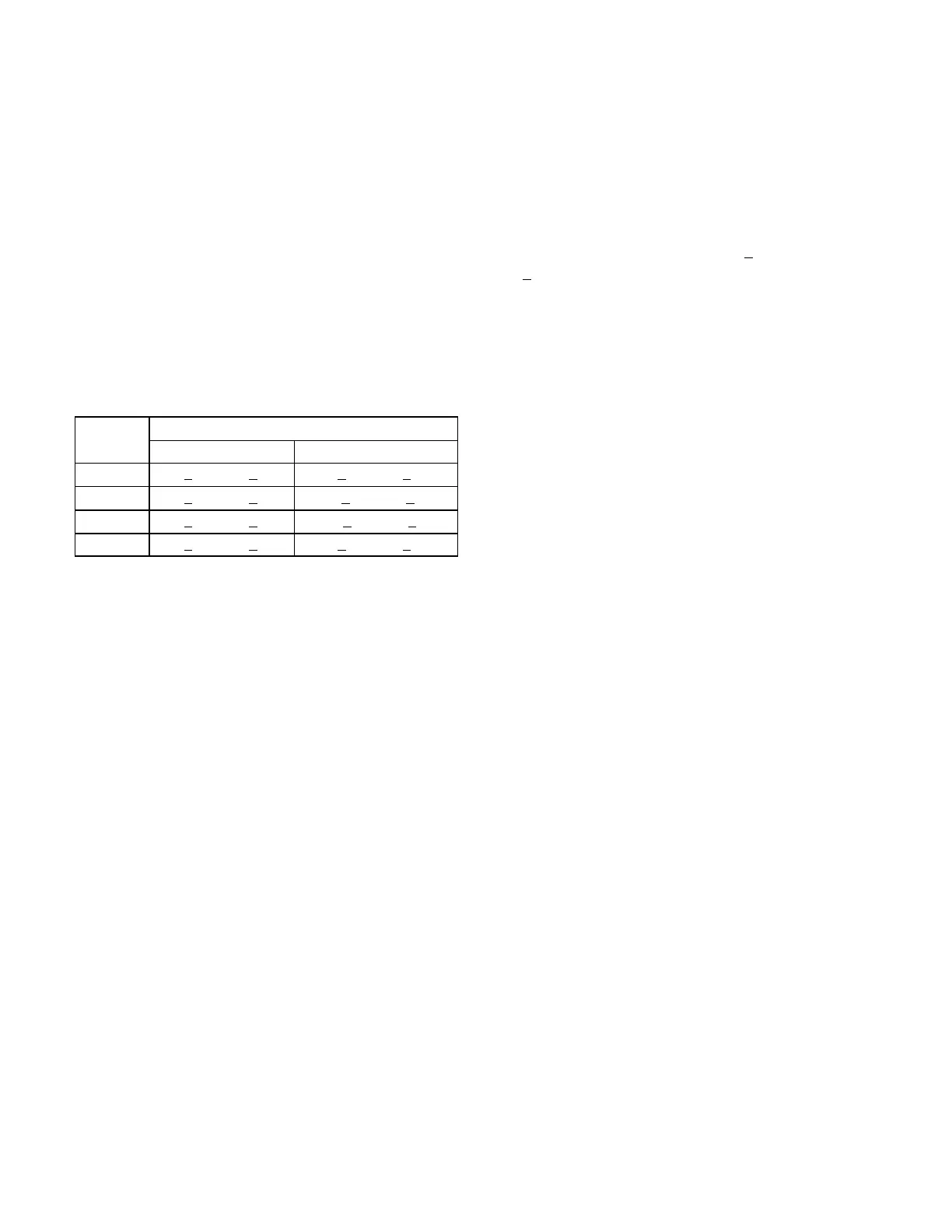

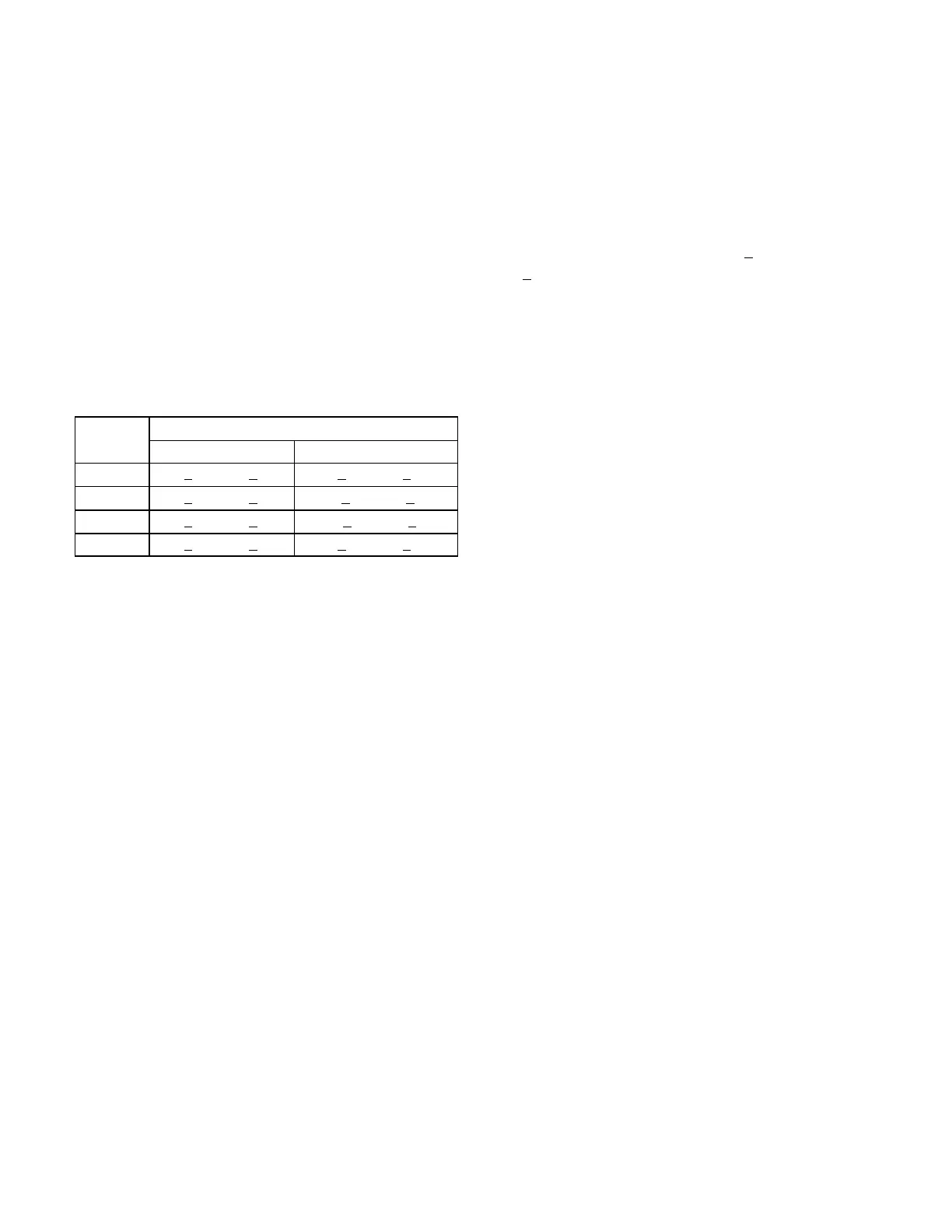

TABLE 15

APPROACH TEMPERATURE - Fin/Tube - TXV

Unit

Liquid Temp. Minus Ambient Temp.

1st Stage 2nd Stage

092S 7°F + 1 (3.9°C + 0.5) 9°F + 1 (5.0°C + 0.5)

102S 5°F + 1 (2.8°C + 0.5) 15°F + 1 (8.3°C + 0.5)

120S 3°F + 1 (1.6°C + 0.5) 2.0°F + 1 (1.1°C + 0.5)

150S 1°F + 1 (0.6°C + 0.5) 3°F + 1 (1.6°C + 0.5)

E-Compressor Controls

See unit wiring diagram to determine which controls are

used on each unit. Optional controls are identified on

wiring diagrams by arrows at junction points.

1- High Pressure Switches (S4, S7)

Compressor circuits are protected by a high pressure

switch which cuts out at 640 psig +

10 psig (4413 kPa

+

70 kPa).

2- Freezestats (S49, S50)

Switches de-energize compressors when evaporator

coil temperature falls below 29°F (-2°C) to prevent

evaporator freeze-up. Switches reset when

evaporator coil temperature reaches 58°F (15°C).

3- Crankcase Heater (HR1, HR2)

Compressors have belly band compressor oil heaters

which must be on 24 hours before running

compressors. Energize by setting thermostat so that

there is no cooling demand, to prevent compressor

from cycling, and apply power to unit.

Loading...

Loading...