Page 21

Service

The unit should be inspected once a year by a qualified

service technician.

CAUTION

Label all wires prior to disconnection when servic

ing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

A-Lubrication

All motors are lubricated at the factory. No further

lubrication is required.

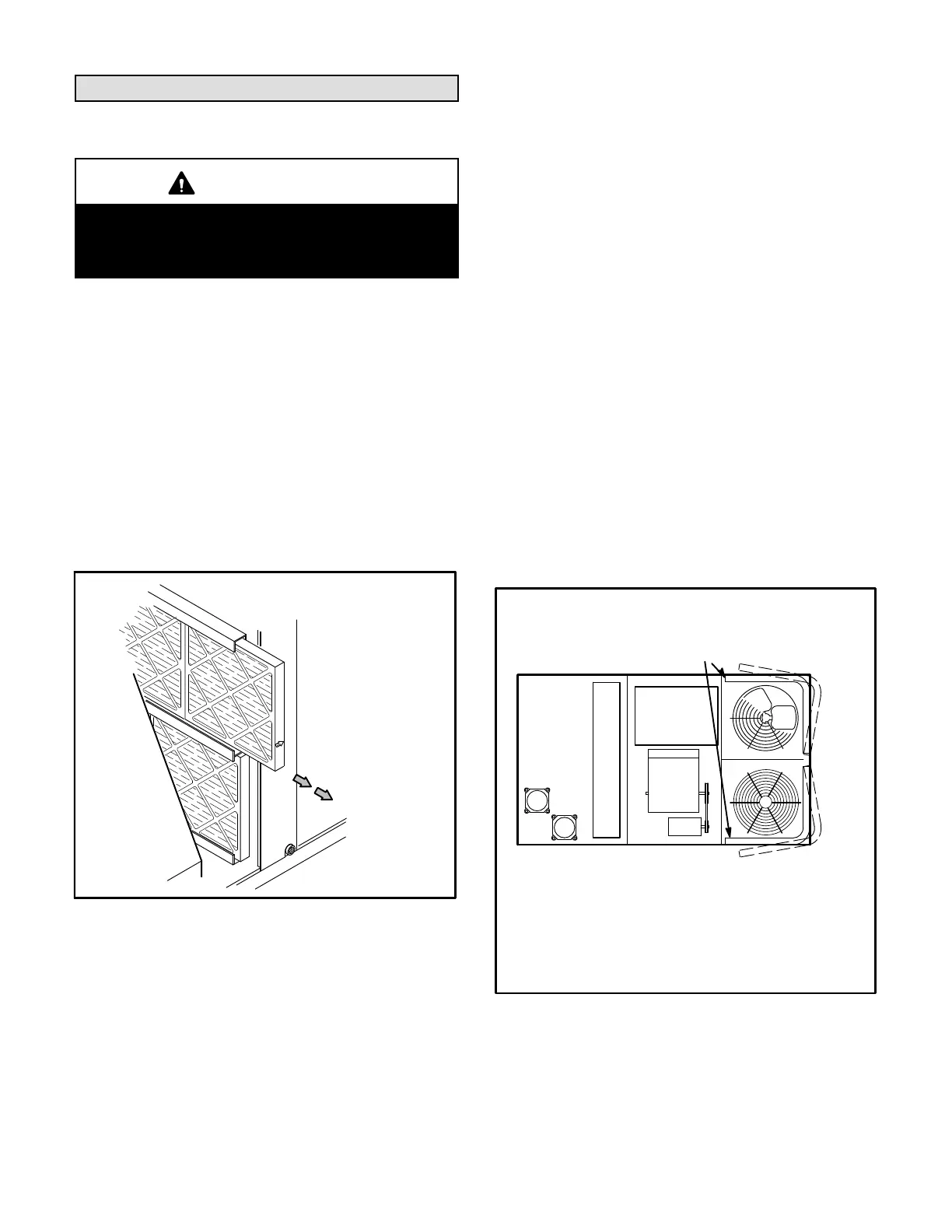

B-Filters

Units are equipped with four 20 X 25 X 2” filters. Filters

should be checked monthly and replaced when

necessary with filters of like kind and size. Take note of

air flow direction marking on filter frame when

reinstalling filters. See figure 18.

NOTE-Filters must be U.L.C. certified or equivalent for

use in Canada.

FIGURE 18

REMOVE FILTERS

PULL TO

REMOVE

FILTERS

C-Supply Air Blower Wheel

Annually inspect supply air blower wheel for accumulated

dirt or dust. Turn off power before attempting to remove

access panel or to clean blower wheel.

D-Indoor Coil

Inspect and clean coil at beginning of each cooling and

heating season. Clean using mild detergent or

commercial coil cleanser. Flush coil and condensate

drain with water taking care not to get insulation, filters

and return air ducts wet.

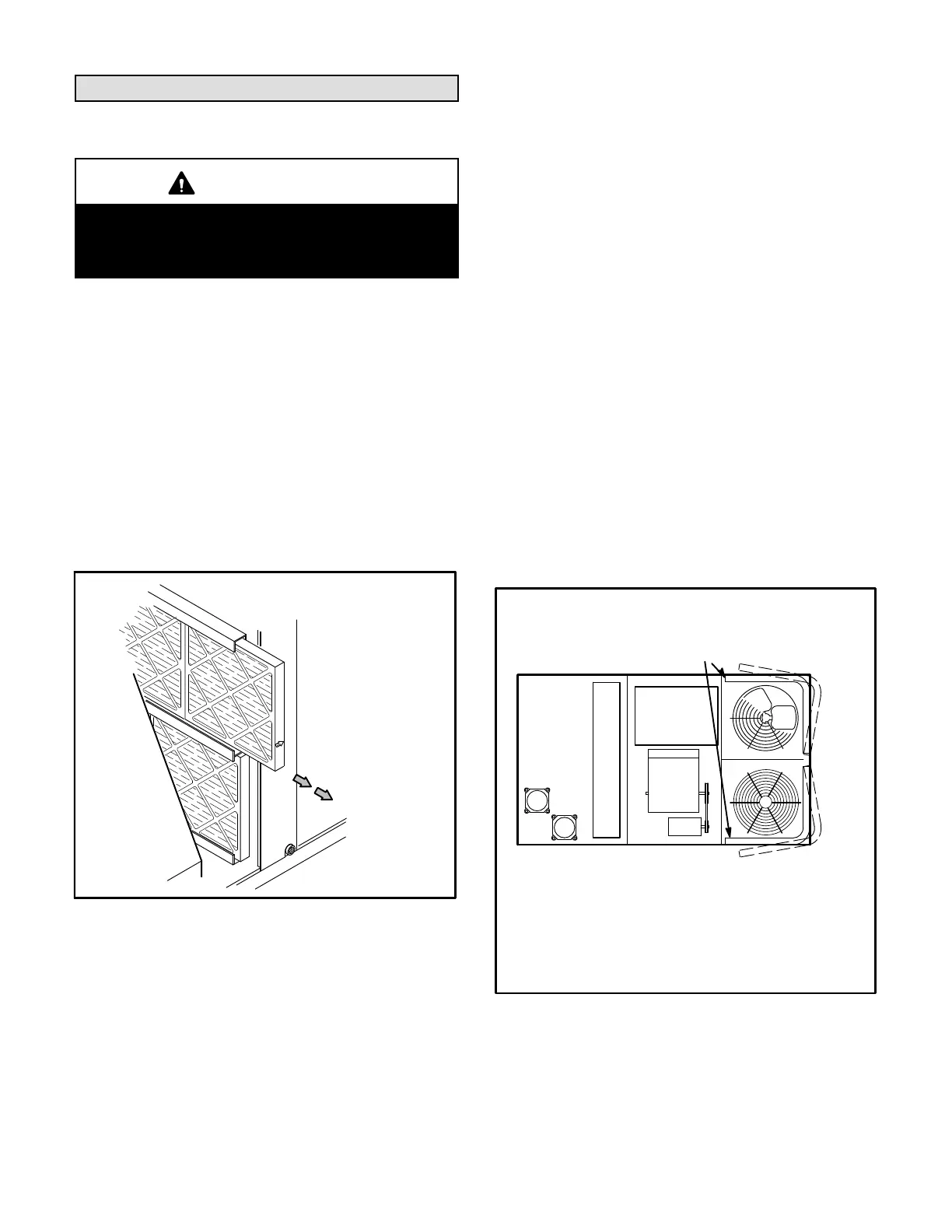

E-Outdoor Coil

Clean condenser coil annually with detergent or

commercial coil cleaner and inspect monthly during the

cooling season.

Condenser coils are made of two formed slabs. Dirt and

debris may become trapped between the slabs. To clean

between slabs, carefully separate coil slabs and wash

them thoroughly. See figure 19. Flush coils with water

following cleaning.

F-Filter Drier

The unit is equipped with a bi-flow filter drier. if

replacement is necessary, order another of like design.

FIGURE 19

1- Remove screws securing coil end plate to mullion.

2- Remove clips connecting coils slabs and separate

slabs 3-4” (76-102mm).

3- Clean coils with detergent or commercial coil cleaner.

4- Rinse thoroughly with water and reassemble.

ENDPLATE IS

SECURED TO MULLION

TOP VIEW

BLOWER

CLEAN CONDENSER COIL (092-120 SHOWN)

Loading...

Loading...