Page 53

V- SYSTEMS SERVICE CHECKS

A-Cooling System Service Checks

LCH units are factory charged and require no further adjust

ment; however, charge should be checked periodically using

the approach method. The approach method compares actual

liquid temperature with the outdoor ambient temperature. See

section IV- CHARGING.

VI-MAINTENANCE

The unit should be inspected once a year by a qualified ser

vice technician.

Electric shock hazard. Can cause

injury or death. Before attempting to

perform any service or maintenance,

turn the electrical power to unit OFF

at disconnect switch(es). Unit may

have multiple power supplies.

WARNING

!

CAUTION

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and danger

ous operation. Verify proper operation after servicing.

A-Filters

Units are equipped with temporary filters which must be

replaced prior to building occupation. See table 27 for

correct filter size. Refer to local codes or appropriate ju

risdiction for approved filters.

Approved filters should be checked monthly and replaced

when necessary. Take note of air flow direction marking on

filter when reinstalling filters.

TABLE 27

Unit Qty Filter Size - inches (mm)

036, 048 4 16 X 20 X 2 (406 X 508 X 51)

060, 072, 074 4 20 X 20 X 2 (508 X 508 X 51)

NOTE-Filters must be U.L.C. certified or equivalent for use

in Canada.

FIGURE 15

REMOVE FILTERS

PULL TO

REMOVE

FILTERS

B-Lubrication

All motors are lubricated at the factory. No further lubrica

tion is required.

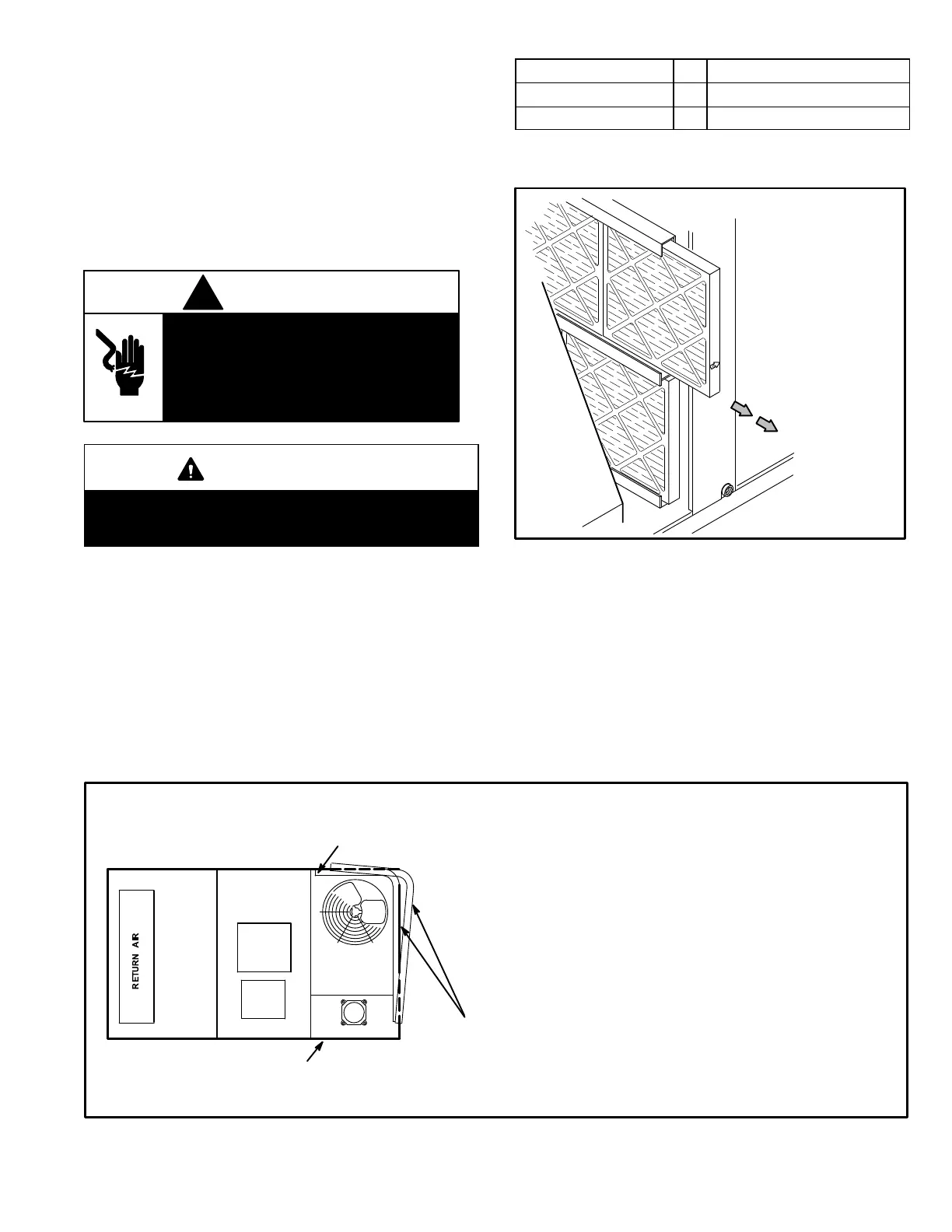

C-Evaporator Coil

Inspect and clean coil at beginning of each cooling season.

Clean using mild detergent or commercial coil cleanser.

Flush coil and condensate drain with water taking care not to

get insulation, filters and return air ducts wet.

FIGURE 16

CLEAN CONDENSER COIL

TOP VIEW

CONDENSER

COILS

BLOWER

CONDENSER ACCESS PANEL

ENDPLATE IS SECURED

TO MULLION

SUPPLY

AIR

1- Remove unit top panel and condenser section access

panel.

2- Remove screws securing coil end plate to mullion.

3- Remove wire ties connecting coils slabs and separate

slabs 3-4” (76-102mm).

4- Clean coils with detergent or commercial coil cleaner.

5- Rinse thoroughly with water and reassemble

. Use

field-provided wire ties to connect coil slabs.

Loading...

Loading...