Page 36

C-Blower Compartment

LCH036H, 048H, and 060H units are equipped with direct

drive blowers. LCH036S, 048S, 060S, -074 units are

equipped with two-speed, belt drive blowers. LCH072H

units are equipped with a single-speed belt drive blower.

See unit nameplate for blower type. The blower compart

ment in all LCH036-074 units is located between the evapo

rator coil and the compressor compartment.

1-Blower Wheels

See table 1 for blower wheel type and size.

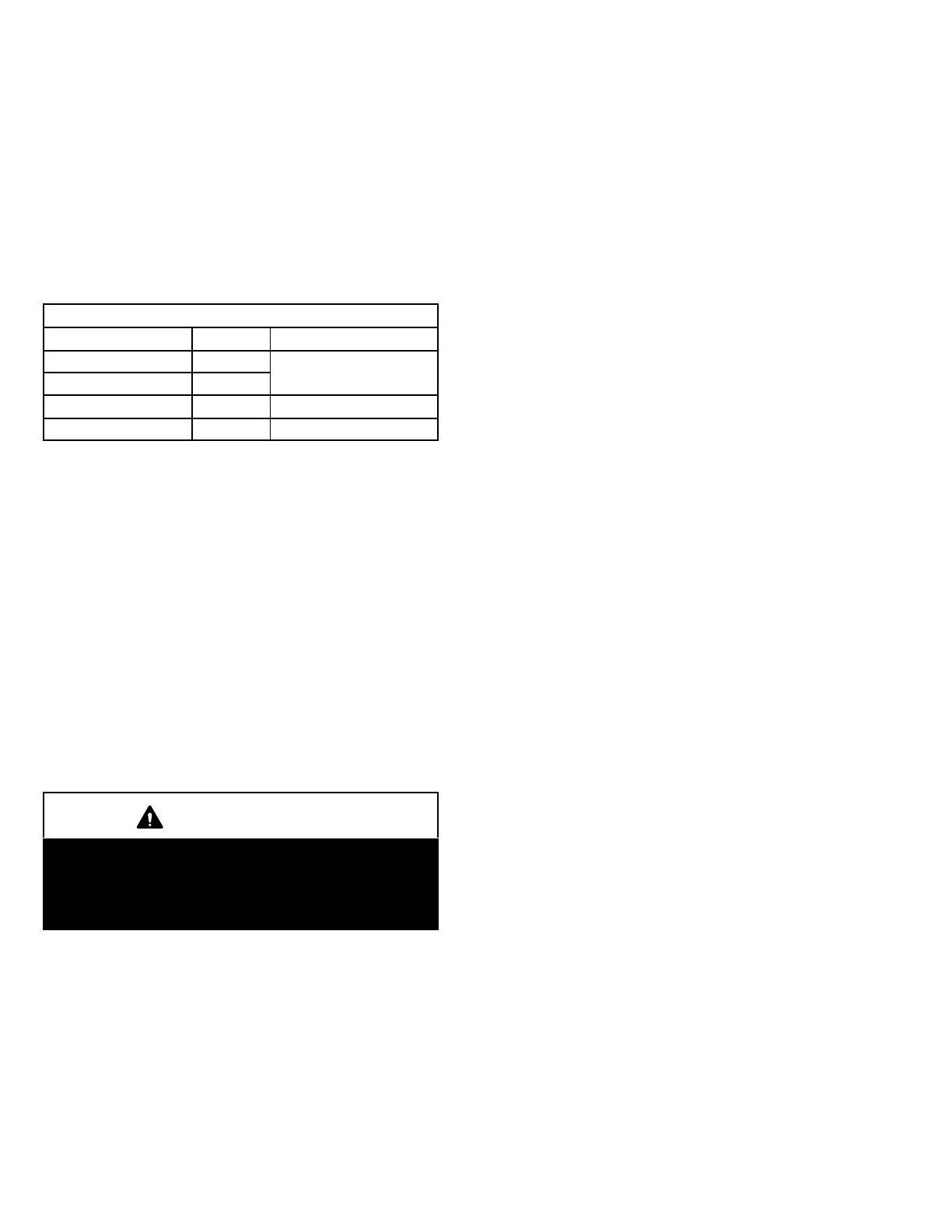

TABLE 1

BLOWER WHEELS

LCH Unit Type Size - in. (mm)

036S, 048S, 060S Belt

10 X 10 (254 X 254)

036H, 048H Direct

060H Direct 11 X 10 (279 X 254)

072H, 074H Belt 15 X 9 (381 X 229)

2-Indoor Blower Motor B3

All direct drive blower motors are electronically commu

tated, brushless, DC motors. Belt drive blower motors are

single (6-ton) or two-speed (3, 4, 5 and 6 ton) integral mo

tors. Low speed is approximately 2/3 of high speed. CFM

adjustments on belt drive units are made by adjusting the

motor pulley (sheave). CFM adjustments on direct drive

units are made by changing ECTO parameters as shown in

the Unit Controller manual provided with each unit. Motors

are equipped with sealed ball bearings. All motor specifica

tions are listed in the SPECIFICATIONS (table of contents)

in the front of this manual. Units may be equipped with mo

tors manufactured by various manufacturers, therefore

electrical FLA and LRA specifications will vary. See unit rat

ing plate for information specific to your unit.

IMPORTANT

Three phase scroll compressors must be phased se

quentially for correct compressor and blower rota

tion. Follow “COOLING START-UP” section of instal

lation instructions to ensure proper compressor and

blower operation.

A-Blower Operation

Refer to the Unit Controller Installation and Setup Guide to

energize blower. Use the menu navigation arrows and se

lect button; see Service - Test.

B-Determining Unit CFM

1- The following measurements must be made with air fil

ters in place.

IMPORTANT - On units equipped with direct drive blowers,

determine and adjust high speed CFM before low speed

CFM. Low speed CFM should be adjusted to 2/3 of high

speed CFM. A low speed adjustment less than 2/3 of high

speed will improve humidity removal; refer to product data

for more information.

2- With all access panels in place, measure static pres

sure external to unit (from supply to return). Pressure

tap locations should be approximately one foot from

openings. See figure 7.

3- Measure the indoor blower wheel RPM. RPM can be

read from the A55 Unit Controller display on direct drive

blowers. See Unit Controller manual.

4- Referring to Page 11 through Page 18, use static pres

sure and RPM readings to determine unit CFM. Use

Page 19 and Page 20 when installing units with any of

the options or accessories listed.

C-Adjusting Unit CFM - Direct Drive Blowers

The supply CFM can be adjusted by changing Unit Control

ler settings; see the Unit Controller guide provided with the

unit. Refer to table 2. Adjustments can also be made by us

ing optional software. Record any CFM changes on the

ECTO Settings label located on the inside of the compres

sor access panel.

D-Adjusting Unit CFM - Belt Drive Blowers

The blower RPM can be adjusted at the motor pulley. Loos

en Allen screw and turn adjustable pulley clockwise in

1/2-turn increments to increase CFM. Turn counterclock

wise in 1/2-turn increments to decrease CFM. See figure 8.

Do not exceed minimum and maximum number of pulley

turns as shown in table 3.

E-Blower Belt Adjustment - Belt Drive

Maximum life and wear can be obtained from belts only if

proper pulley alignment and belt tension are main

tained. Tension new belts after a 24-48 hour period of op

eration. This will allow belt to stretch and seat grooves.

Make sure blower and motor pulley are aligned as shown in

figure 9.

1- Loosen four bolts securing motor base to mounting

frame. See figure 8.

2- To increase belt tension -

Slide blower motor downward to tighten the belt. This

increases the distance between the blower motor and

the blower housing.

3- To loosen belt tension -

Slide blower motor upward to loosen the belt. This de

creases the distance between the blower motor and

the blower housing.

4- Tighten four bolts securing motor base to the mounting

frame.

Loading...

Loading...