Page 47

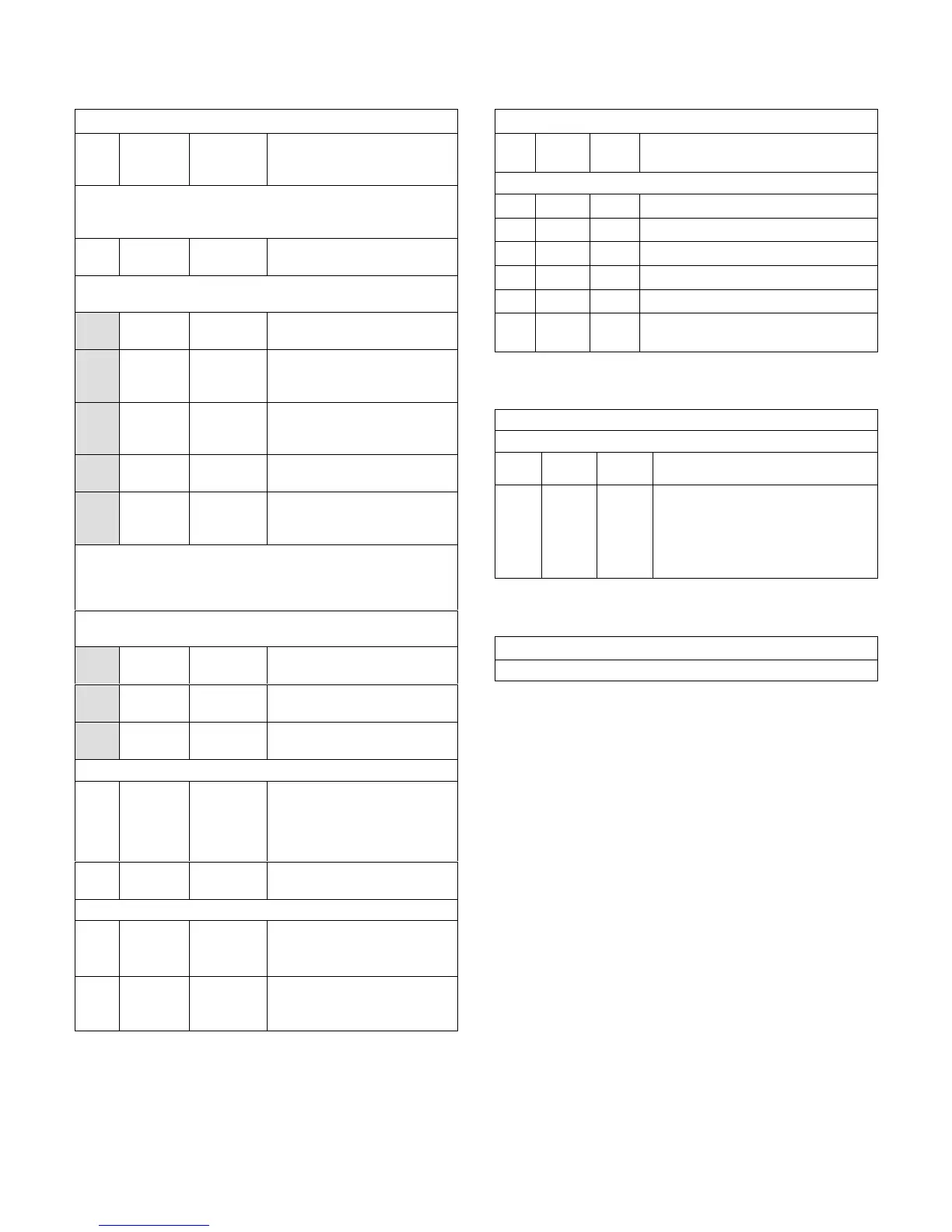

TABLE 37

580683

LGH/LCH 094U4E (2-Compressor) Staged Direct Drive

Para

met

er

Factory

Setting

Field

Setting

Description

Note: Any changes to Smoke CFM setting must be adjusted be

fore the other CFM settings. Use SETTINGS > RTU OPTIONS >

EDIT PARAMETERS

12

3000

CFM

CFM

Blower CFM during smoke

detection.

SETUP > TEST & BALANCE (can also use SETTINGS > RTU

OPTIONS > BLOWER > SPEEDS)

3000

CFM

CFM

Blower CFM during heating.

3000

CFM

CFM

Blower CFM during high speed

cooling (2 compressor)

operation.

1950

CFM

CFM

Blower CFM during low speed

cooling (1 compressor)

operation.

3000

CFM

CFM

Blower CFM during ventilation.

1195

RPM

RPM*

Adjust RPM based on unit static

and blower tables to reach tar

get CFM.

*Once all four blower settings are entered, the target (highest of the

heating and cooling settings) CFM will be displayed. Once the RPM

is saved for the target CFM, all other blower RPM values are set by

the Unit Controller according to the field CFM setting..

SETUP > TEST & BALANCE (can also use SETTINGS > RTU

OPTIONS > DAMPER)

0% %

Damper min. position during

LOW blower operation.

0% %

Damper min. position during

HIGH blower operation.

0% %

Power exhaust position during

HIGH blower operation.

SETTINGS > RTU OPTIONS > EDIT PARAMETERS

29 101% %Open

Damper minimum position during

G blower operation. (Setting para

meter 29 to “101” disables para

meter 29 and passes control to

parameter 9 or 132)

216 5% %

Deadband % for stage 1 power

exhaust operation.

SETTINGS > RTU OPTIONS > EDIT PARAMETER

85 40°F °F

Compressor 1 low temp lockout.

Settings lower than 40°F could

void warranty.

86 40°F °F

Compressor 2 low temp lockout.

Settings lower than 40°F could

void warranty.

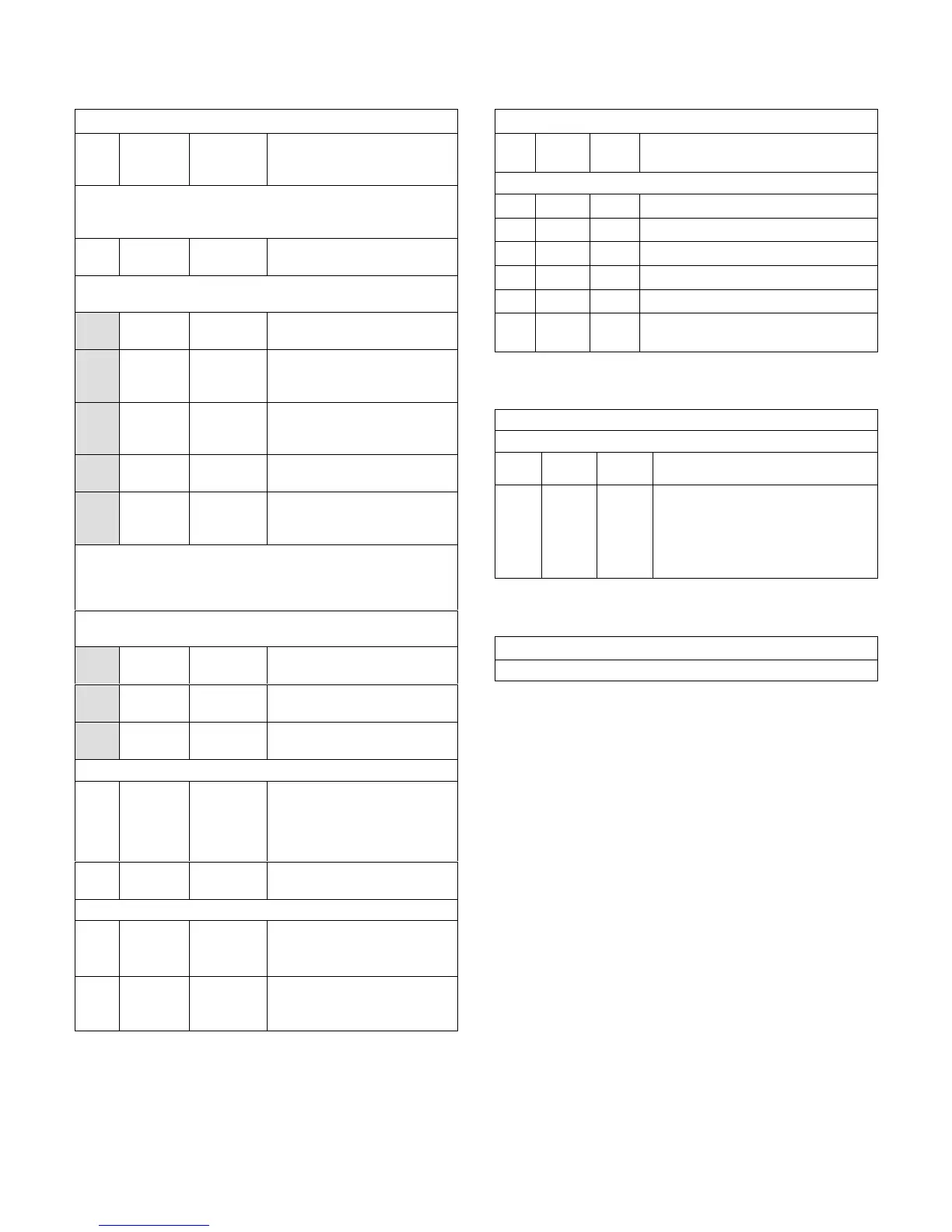

TABLE 38

580731

Units With Automated Logic DDC (Target) Settings

Para

meter

Factory

Setting

Field

Setting

Description

Use SETTINGS > RTU OPTIONS > EDIT PARAMETERS

91 120 Compressor minimum run time.

111 3 Thermostat with three cooling stages.

118 400 Damper “start open” CO

2

setpoint for DCV.

119 2000 Damper “full open” CO

2

setpoint for DCV.

139 74 Backup occupied cooling setpoint.

153 60

Time delay between heating and cooling

mode.

TABLE 39

580734

Units With Hot Gas Reheat

Use SETTINGS > RTU OPTIONS > EDIT PARAMETERS

Para

meter

Factory

Setting

Field

Setting

Description

105 6

Hot Gas Reheat Option 6: Reheat is

only possible if blower is energized dur

ing occupied periods. Controlled by RH

sensor (A91) connected to input

A55_P298_5 and set point set at para

meter 106 (default 60%).

TABLE 40

580743

Units With LonTalk Settings

Use menu SETUP > NETWORK INTEGRATION. Set “LONTALK”.

Loading...

Loading...