Page 46

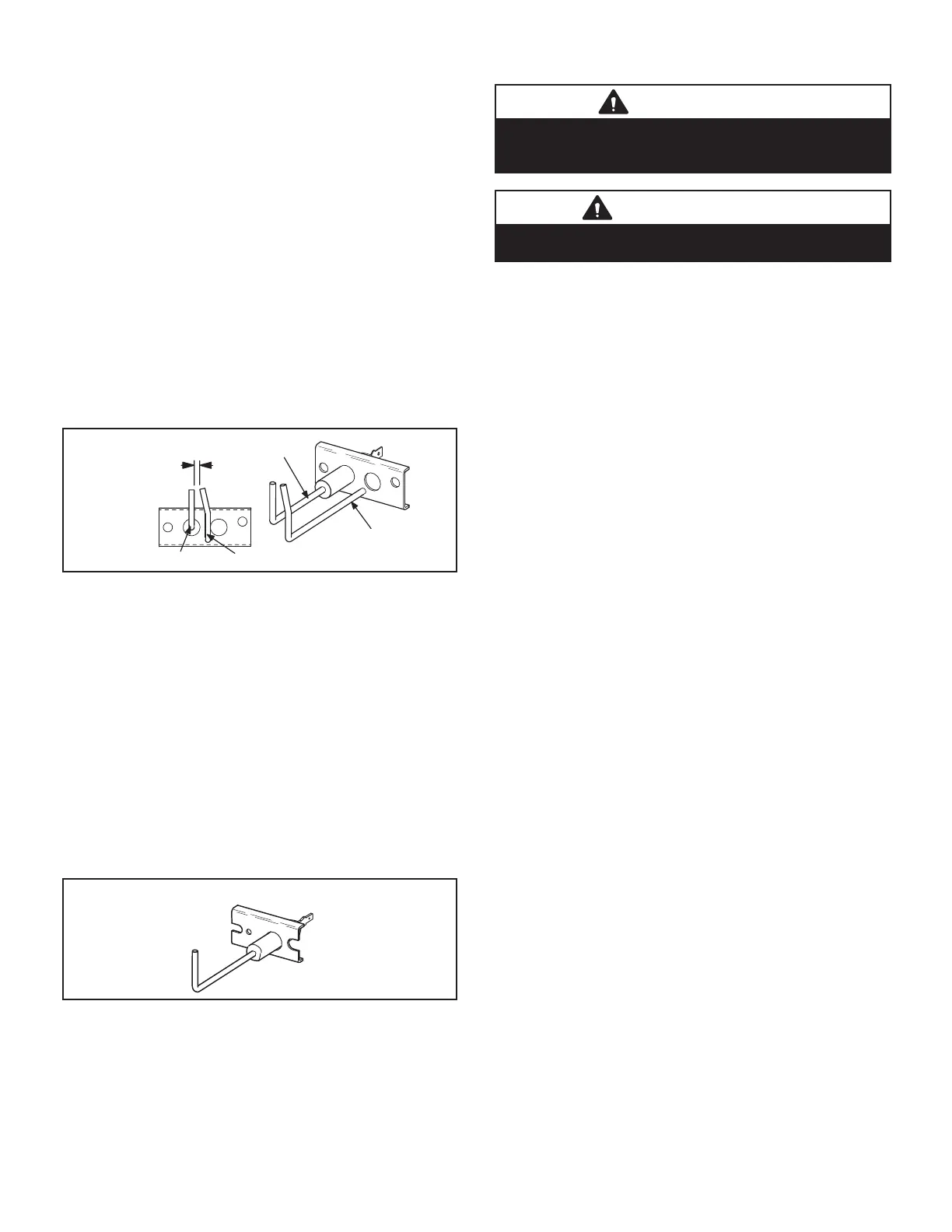

10-Spark Electrodes

An electrode assembly is used for ignition spark. Two

identical electrodes are used (one for each gas heat sec-

tion). The electrode is mounted through holes on the left

-most end of the burner support. The electrode tip pro-

electrode assembly is fastened to burner supports and

can be removed for service without removing any part of

the burners.

During ignition, spark travels through the spark electrode

burner to burner until all are lit.

The spark electrode is connected to the ignition control

by a 8 mm silicone-insulated stranded high voltage wire.

The wire uses 1/4” (6.35 mm)female quick connect on the

electrode end and female spark plug-type terminal on the

ignition control end.

NOTE- IN ORDER TO MAXIMIZE SPARK ENERGY TO

ELECTRODE, HIGH VOLTAGE WIRE SHOULD TOUCH

UNIT CABINET AS LITTLE AS POSSIBLE.

GROUND

ELECTRODE

GROUND

ELECTRODE

.125” ± .015”

(3.2 mm ± .4 mm)

FIGURE 24

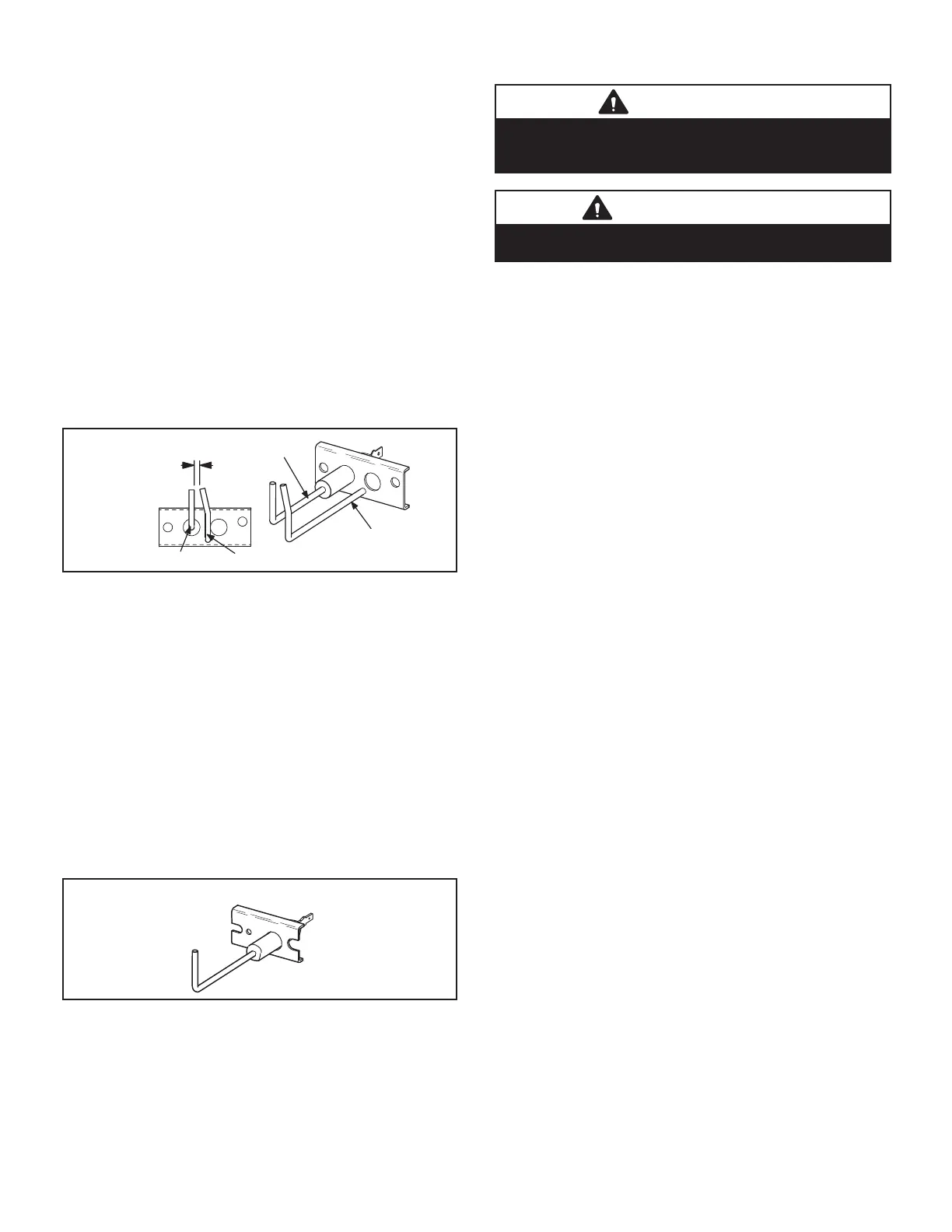

11-Flame Sensors

-

er support. The sensor is mounted through a hole in the

-

lope of the right most burner. The sensor assembly is fas-

tened to burner supports and can be removed for service

without removing any part of the burners.

-

passed along the ground electrode (located on the spark

-

trode. The ignition control allows the gas valve to stay

FIGURE 25

II-PLACEMENT AND INSTALLATION

Make sure the unit is installed in accordance with the in-

stallation instructions and all applicable codes. See ac-

cessories section for conditions requiring use of the op-

tional roof mounting frame.

III-CHARGING

WARNING

Refrigerant can be harmful if it is inhaled. Refrigerant

must be used and recovered responsibly. Failure to follow

this warning may result in personal injury or death.

IMPORTANT

Units equipped with Hot Gas Re-Heat system MUST be

charged in standard cooling mode.

A-Aluminum Coils

WARNING-Do not exceed nameplate charge under

any condition.

This unit is factory charged and should require no further

adjustment. If the system requires additional refrigerant,

reclaim the charge, evacuate the system, and add re-

quired nameplate charge.

NOTE - System charging is not recommended below 60 F

(15 C). In temperatures below 60 F (15 C), the charge must

be weighed into the system.

If weighing facilities are not available, or to check the

charge, use the following procedure:

IMPORTANT - Charge unit in standard cooling mode.

1 - Make sure outdoor coil is clean. Attach gauge

manifolds and operate unit at full CFM in cooling

mode with economizer disabled until system

all outdoor air dampers are closed.

2 - Check each system separately with all stages

operating. Compare the normal operating pressures

(see tables 11 - 23) to the pressures obtained from

the gauges. Check unit components if there are

3 - Measure the outdoor ambient temperature and

the suction pressure. Refer to the appropriate

circuit charging curves to determine a target liquid

temperature.

Note - Pressures are listed for sea level applications.

4 - Use the same thermometer to accurately measure

the liquid temperature (in the outdoor section).

• If measured liquid temperature is higher than the

target liquid temperature, add refrigerant to the sys-

tem.

• If measured liquid temperature is lower than the

target liquid temperature, recover some refrigerant

from the system.

5 - Add or remove charge in increments. Allow the

system to stabilize each time refrigerant is added

or removed.

6 - Continue the process until measured liquid

temperature agrees with the target liquid

temperature. Do not go below the target liquid

temperature when adjusting charge. Note that

suction pressure can change as charge is adjusted.

7 -

ambient and a measured suction pressure of

or

in increments until measured liquid temperature

agrees with the target liquid temperature.

Loading...

Loading...