Page 85

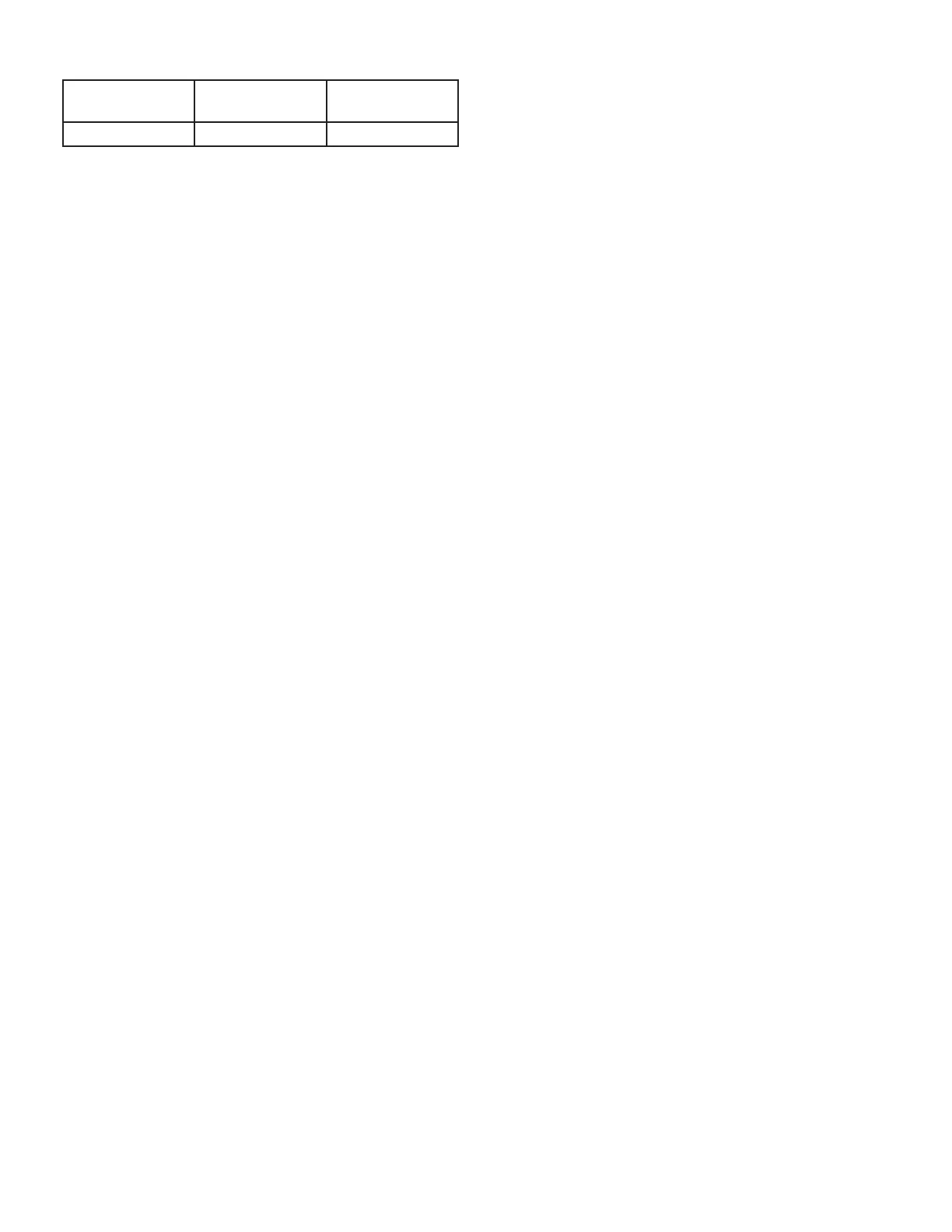

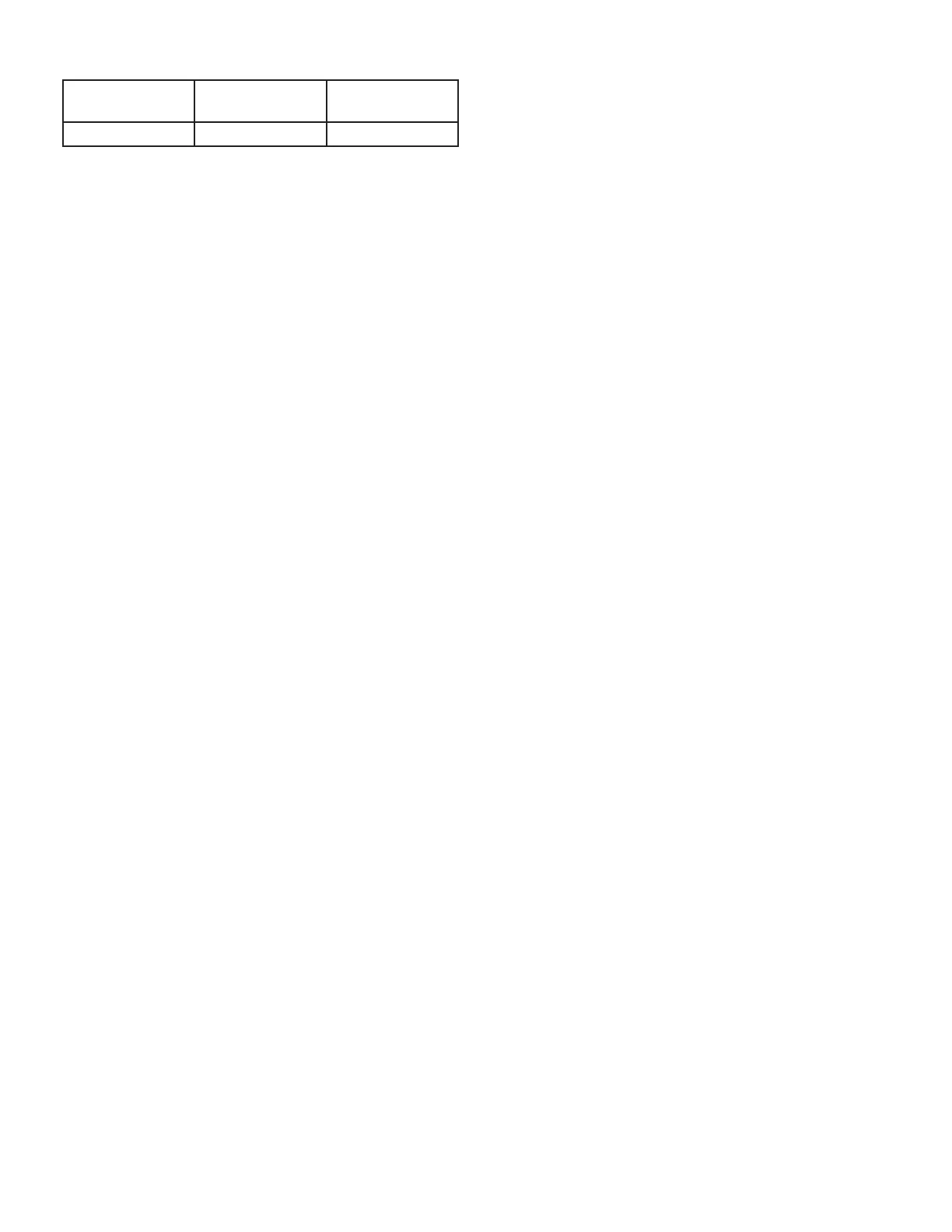

TABLE 38

Manufacturer

Nominal Signal

Microamps

Drop Out

UTEC 0.5 - 1.0

NOTE-If the meter scale reads 0, the leads are reversed.

Disconnect power and reconnect leads for proper polarity

10-Combustion Air Inducer

adjustable. However, operation should be monitored to

ensure proper operation. The combustion air inducer is

used to draw fresh air into the combustion chamber while

simultaneously expelling exhaust gases. The inducer op-

erates throughout the heating cycle.

On a heating demand, the ignition control is energized by

the A55 Unit Controller. The ignition control then allows

30 to 40 seconds for the combustion air inducer to vent

exhaust gases from the burners. When the combustion

air inducer is purging the exhaust gases, the combustion

air prove switch is closing proving that the combustion air

inducer is operating before allowing the ignition control to

energize. When the combustion air prove switch is closed

11-High Altitude

Units may be installed at altitudes up to 2000 feet (610

above 2000 ft see “HIGH ALTITUDE DERATE” in “SPECI-

FICATIONS - GAS HEAT” at the front this manual.

B-Cooling System Service Checks

LGH units are factory charged and require no further ad-

using the approach method. The approach method com-

pares actual liquid temperature with the outdoor ambient

temperature. See section III- CHARGING.

NOTE-When unit is properly charged discharge line pres-

sures should approximate those in tables 11 through 36.

1-Oil Check Injection Procedure 180U, 240U, 300U

1 - Run the unit in full load (both compressors running)

for a minimum of thirty (30) minutes or until

2 - Check the oil level of the tandem compressor

assembly using the sight glass installed in the oil

equalization line near the base of the compressors.

The oil level should be visible in the sight glass,

preferably in the middle.

3 - If the oil level is not visible in the sight glass continue

on to steps 4-17 to add oil to the tandem compressor

system( POE 32-3MAF oil recommended). The A/C

catalogue number Y6630 is recommended for use

when adding oil to a system.

4 - With the unit running in full load, connect the high

side manifold gauge hose to the open pressure tap

valve to purge the high side and middle manifold

gauge hoses.

5 - Connect the oil injector container to the middle

manifold gauge hose. Remove the container from

the lid (the end attached to the middle manifold

gauge hose).

6 - Attach a hose to the opposite end of the oil container

(this hose is provided and is already attached to the

oil container in the recommended injection kit listed

above).

7 - Clean the oil container of contaminants and debris.

the oil container (POE 32-3MAF oil recommended).

8 - Re-install the lid, attached to the middle manifold

gauge hose, onto the oil container.

side manifold gauge valve to pressurize the hoses

and oil container.

10 - Lightly thread the hose coming from the oil

the oil equalization line located near the base of the

compressors (See Figure 31). Do not depress the

Schrader Valve..

11 -

the oil equalization line port.

12 -

gauge hose and the oil container to pressurize with

suction pressure.

13 - Open the high side manifold gauge valve for no

more than 2 seconds to allow the contents of the oil

Loading...

Loading...