Page 86

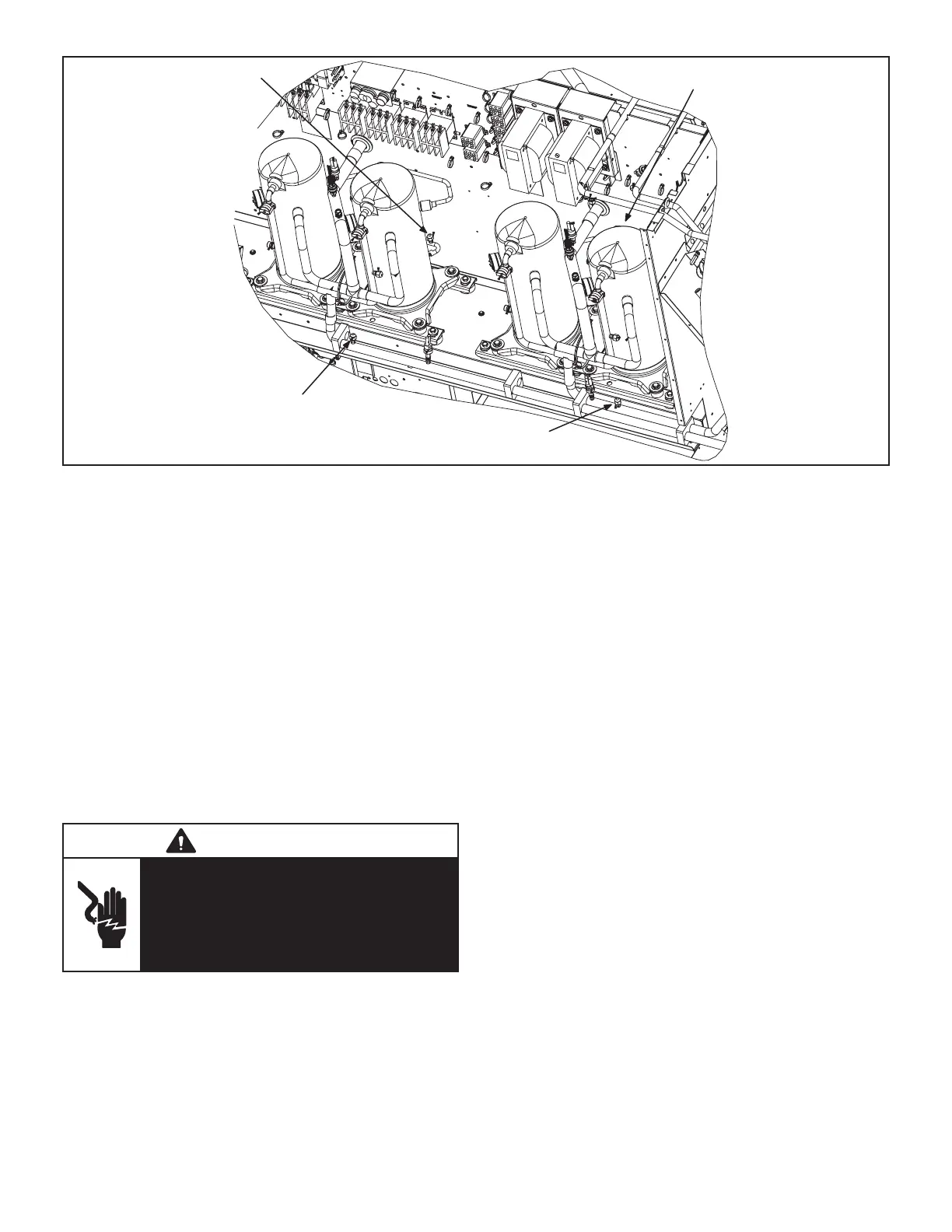

Circuit 1 Oil Equalization Port

Circuit 1 Oil Discharge Port

Circuit 2 Oil Discharge Port

Circuit 2 Oil Equalization Port

(not shown, behind compressor 4)

FIGURE 31

14 - Allow the unit to continue to run in full load for a

minimum of 5 minutes to allow the new oil level

to stabilize. Re-check the oil level of the tandem

compressor assembly.

15 -

on the hose attached to the oil equalization port and

repeat steps 4 - 14 until oil level is in the middle of

the sight glass.

16 -

the oil equalization line..

17 -

pressures to equalize. Disconnect high side

manifold gauge hose from the common discharge

line.

VI-MAINTENANCE

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at disconnect

switch(es). Unit may have multiple power

supplies.

A-Filters

more frequently in severe use) and cleaned or replaced

regularly. Take note of the “AIR FLOW DIRECTION” mark-

B-Lubrication

All motors and blower wheels used in LGH units are lubri-

C-Supply Air Blower Wheel

Annually inspect supply air blower wheel for accumulated

access panel or to clean blower wheel.

D-Evaporator Coil

Inspect and clean coil at beginning of each season. Clean

using mild detergent or commercial coil cleanser. Check

condensate drain pan and line, if necessary. Flush coil

and condensate drain with water taking care not to get in-

lines and coil for evidence of oil and refrigerant leaks.

E-Condenser Coil

Clean condenser coil annually with detergent or commer-

cial coil cleaner and inspect monthly during the cooling

season. Check connecting lines and coil for evidence of

oil and refrigerant leaks.

F-Electrical

1 - Check all wiring for loose connections.

2 - Check for correct voltage at unit (unit operating).

3 - Check amp-draw on both condenser fan motor and

blower motor.

Fan Motor Rating Plate ____ Actual ________

Indoor Blower Motor Rating Plate____ Actual____

Loading...

Loading...