C-Zone Sensor (4 Clg. Stages), 4-Compressor Units

1-Economizer With Outdoor Air Suitable Y1 Demand -

Blower Cooling Low

Dampers modulate

Y2 Demand -

Blower Cooling High

Dampers Modulate

156, 180H, 210, 240H, 300S - If dampers are at maximum

open for three minutes, compressor 1 is energized and

blower stays on cooling high.

180U, 240U, 300U - If dampers are at maximum open for

three minutes, two compressors (one from each circuit)

are energized and blower stays on cooling high.

Y3 Demand -

Compressors 1 and 2 On

180U, 240U, 300U - Two Compressors On

(one from each circuit)

Blower Cooling High

Dampers Maximum Open

Y4 Demand -

All Compressors On

Blower Cooling High

Dampers Maximum Open

2-No Economizer or Outdoor Air Not Suitable

Y1 Demand -

Compressor 1 On

180U, 240U, 300U - Two Compressors On

(one from each circuit)

Blower Cooling Low

Y2 Demand -

Compressors 1 and 2 On

180U, 240U, 300U - Two Compressors On

(one from each circuit)

Blower Cooling Medium Low

Y3 Demand -

Compressors 1, 2 and 3 On

180U, 240U, 300U, any three compressors are On

Blower Cooling Medium High

Y4 Demand -

All Compressors On

Blower Cooling High

X--VAV System

Refer to the installation instructions for additional informa-

tion and available replacements.

Units may contain an optional supply air blower equipped

supply air CFM.

-

NOTE - Units equipped a Variable Frequency Drive (VFD)

are designed to operate on balanced, three-phase power.

Operating units on unbalanced three-phase power will re-

duce the reliability of all electrical components in the unit.

Unbalanced power is a result of the power delivery system

supplied by the local utility company. Factory-installed in-

verters are sized to drive blower motors with an equiva-

lent current rating using balanced three-phase power. If

unbalanced three-phase power is supplied; the installer

must replace the existing factory-installed inverter with an

inverter that has a higher current rating to allow for the

imbalance.

A-Start-Up

1 - A pressure transducer (A30) is shipped in a box

in the blower compartment. Install the transducer

according to manufacturer's instructions.

Note - Make sure the transducer is installed in the

main duct at least 2/3 of the distance away from the

unit.

2 - Two twisted pairs of shielded cable must be used to

P300 connector is hanging in the control box.

3 - Open all zone dampers and/or boxes.

4 -

5 - Use the Unit Controller to calibrate the blower CFM.

Select the SETUP->TEST & BALANCE->BLOWER

menu to start the blower. The Unit Controller

will display the percent of blower speed. Adjust

6 - Press SAVE to display the current static pressure. If

press SAVE again to set the setpoint. If the static

adjust the pressure and press SAVE to set the

setpoint.

7 - Record new setpoints in table 43.

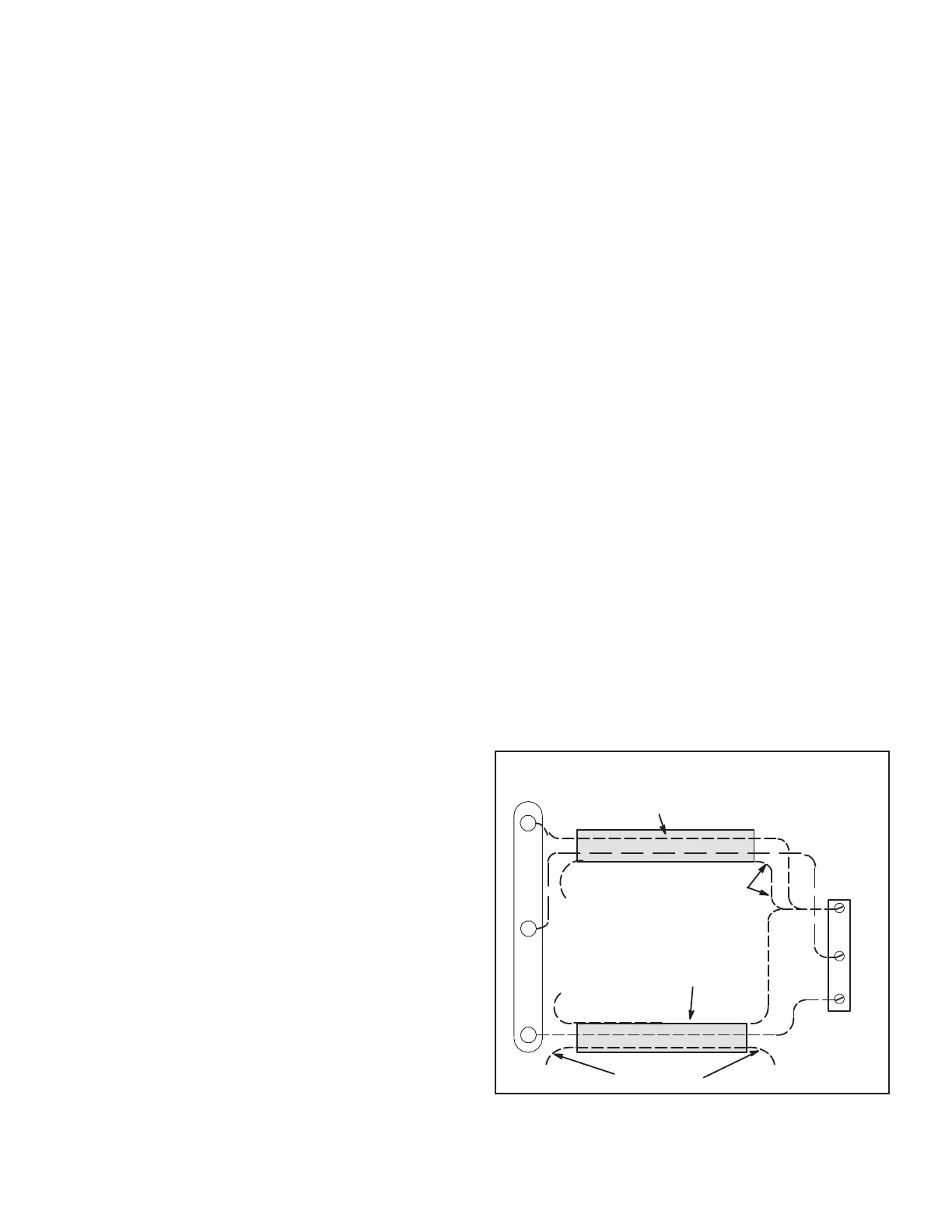

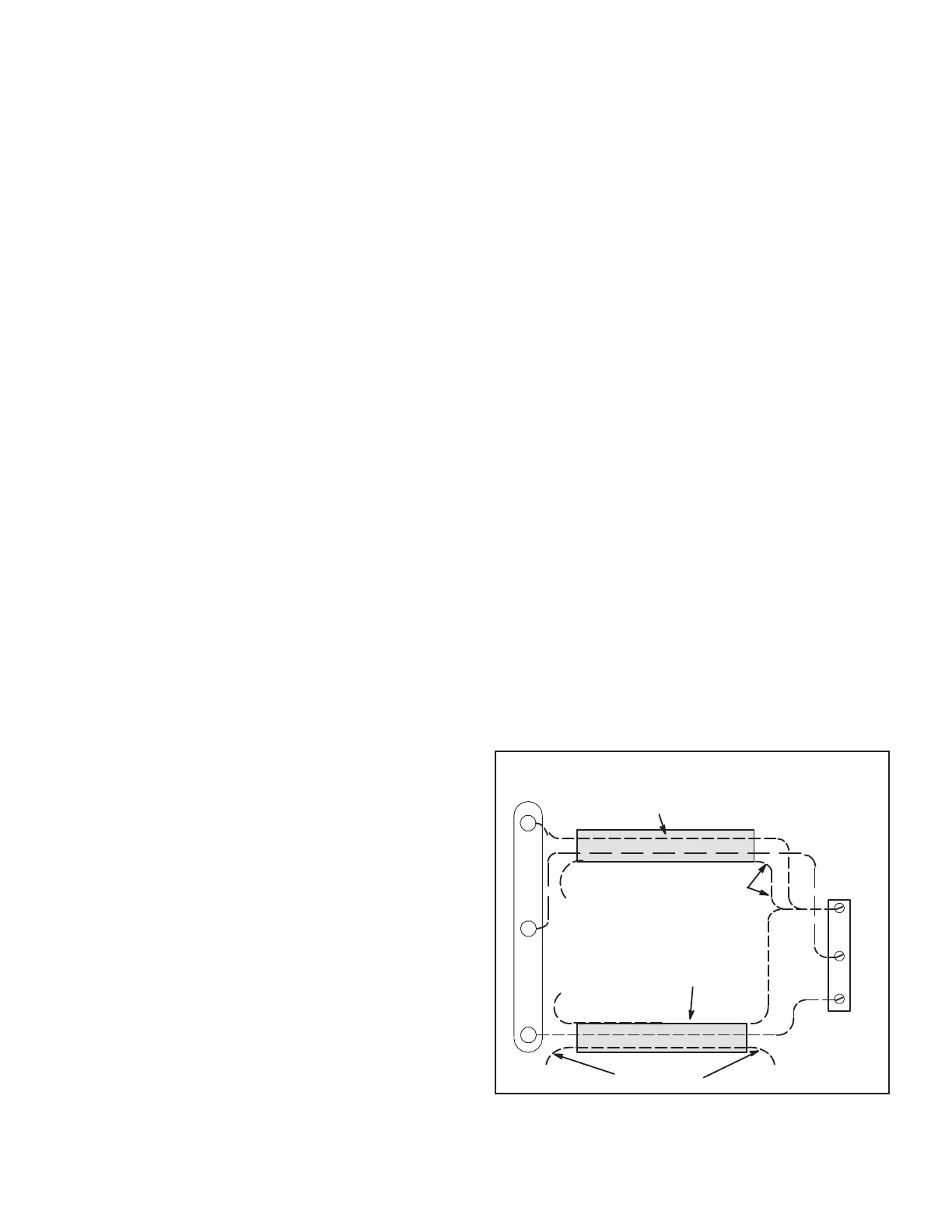

PRESSURE TRANSDUCER WIRING

TWISTED

PAIR

UNUSED WIRE

DRAIN

NOT

CONNECTED

NOT

CONNECTED

TWISTED

PAIR

A30

+S

_

+

J300

1

2

3

FIGURE 40

Loading...

Loading...