16

Table 3. Refrigerant Piping and Indoor Unit

Liquid Line

in.

Gas Line

in.

24000, 36000 &

48000

3/8 5/8

A

B

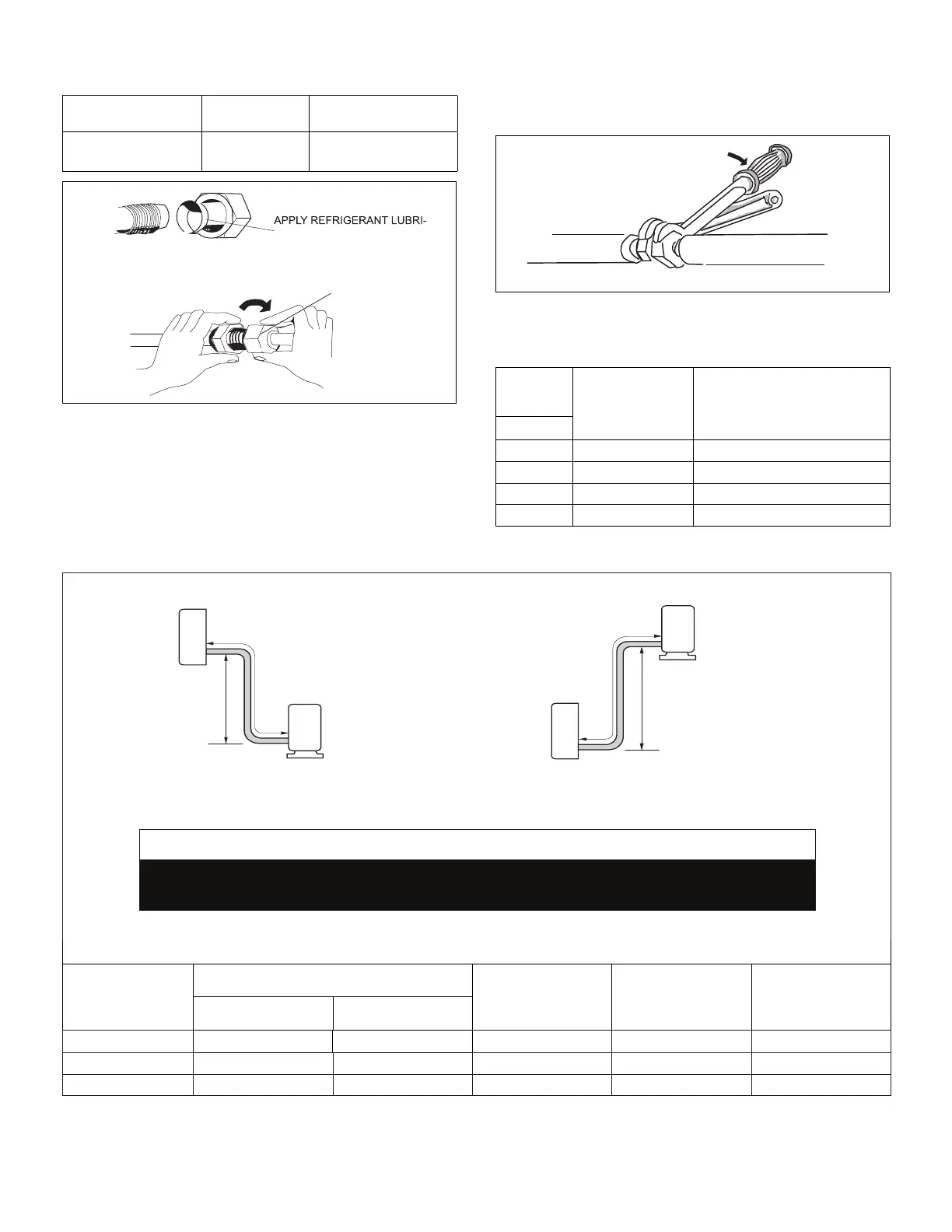

CANT ON THE OUTSIDE OF

THE FLARE

MALE FLARE

CONNECTION

Figure 31.

16. Once snug, continue another half-turn on each nut

which should create a leak-free joint. A torque wrench

may be used to tighten are nuts using “Table 4. Flare

Nut Torque Recommendations” on page 16. Do

17. After refrigerant piping has been installed and checked

for leaks, apply insulation over all ared connections.

TORQUE WRENCH

TO INDOOR

UNIT

TO OUTDOOR UNIT

BACKUP

WRENCH

Figure 32. Tighten Flare Nut

Table 4.

Outside

Diameter

Torque

Finger tighten and use an

appropriately sized wrench to

turn an additional:

1/4 15 ft.-lb. (20 N) 1/4 turn

3/8 26 ft.-lb. (35 N) 1/2 turn

1/2 41 ft.-lb. (56 N) 7/8 turn

5/8 48 ft.-lb. (65 N) 1 full turn

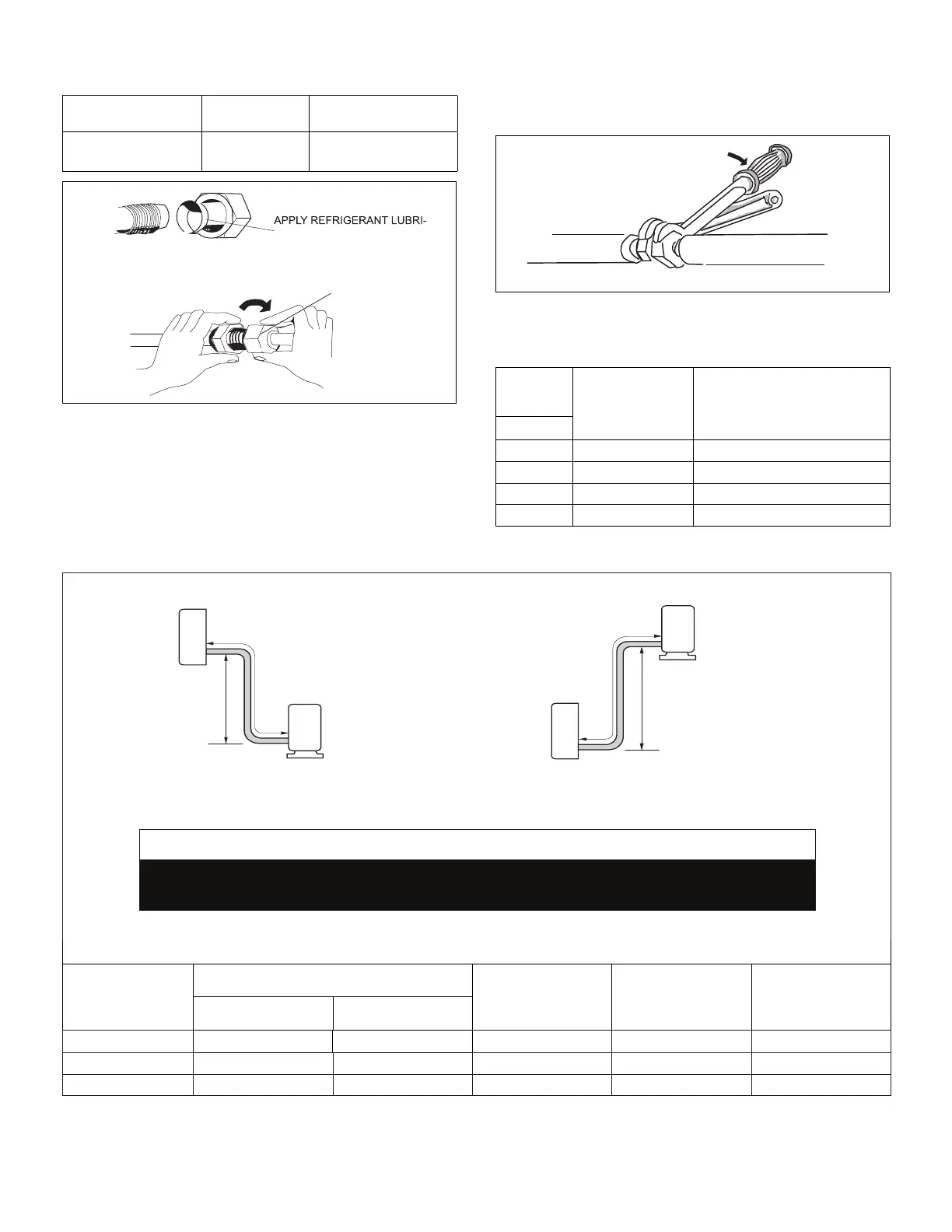

Table 5. Refrigerant Line Set Requirements

OUTDOOR UNIT

OUTDOOR UNIT

INDOOR UNIT

INDOOR UNIT

Maximum Line Set

Length

Maximum Line Set

Length

Maximum

Elevation -

Outdooor

Unit BELOW

Indoor Unit

Maximum

Elevation -

Outdooor

Unit ABOVE

Indoor Unit

Minimum Line Set

Length - 10 ft. (3m)

Minimum Line Set

Length - 10 ft. (3m)

Outside Unit BELOW Indoor Unit Outside Unit ABOVE Indoor Unit

Do not allow for excess length of line sets to be left rolled up as part of the

required distance, or in general. This will also cause additional performance issues.

IMPORTANT

Each system size has a line set length and vertical elevation parameters.

Maximum Elevation

Outdoor Unit BELOW

Indoor Unit - Feet

Maximum Elevation

Outdoor Unit ABOVE

Indoor Unit - Feet

Maximum Line

Set Length - Feet

Liquid Gas

018

1/4 1/2

66 ft. (20 m) 66 ft. (20 m) 98 ft. (30 m)

024 3/8 5/8 82 ft. (25 m) 82 ft. (25 m) 164 ft. (50 m)

036/048 3/8 5/8 98 ft. (30 m) 98 ft. (30 m) 213 ft. (65 m)

Loading...

Loading...