Page 27

Blower Delay Select

SW2-1 SW2-2

60 OFF ON

90 OFF OFF

120 ON OFF

180 ON ON

Factory Setting is 90

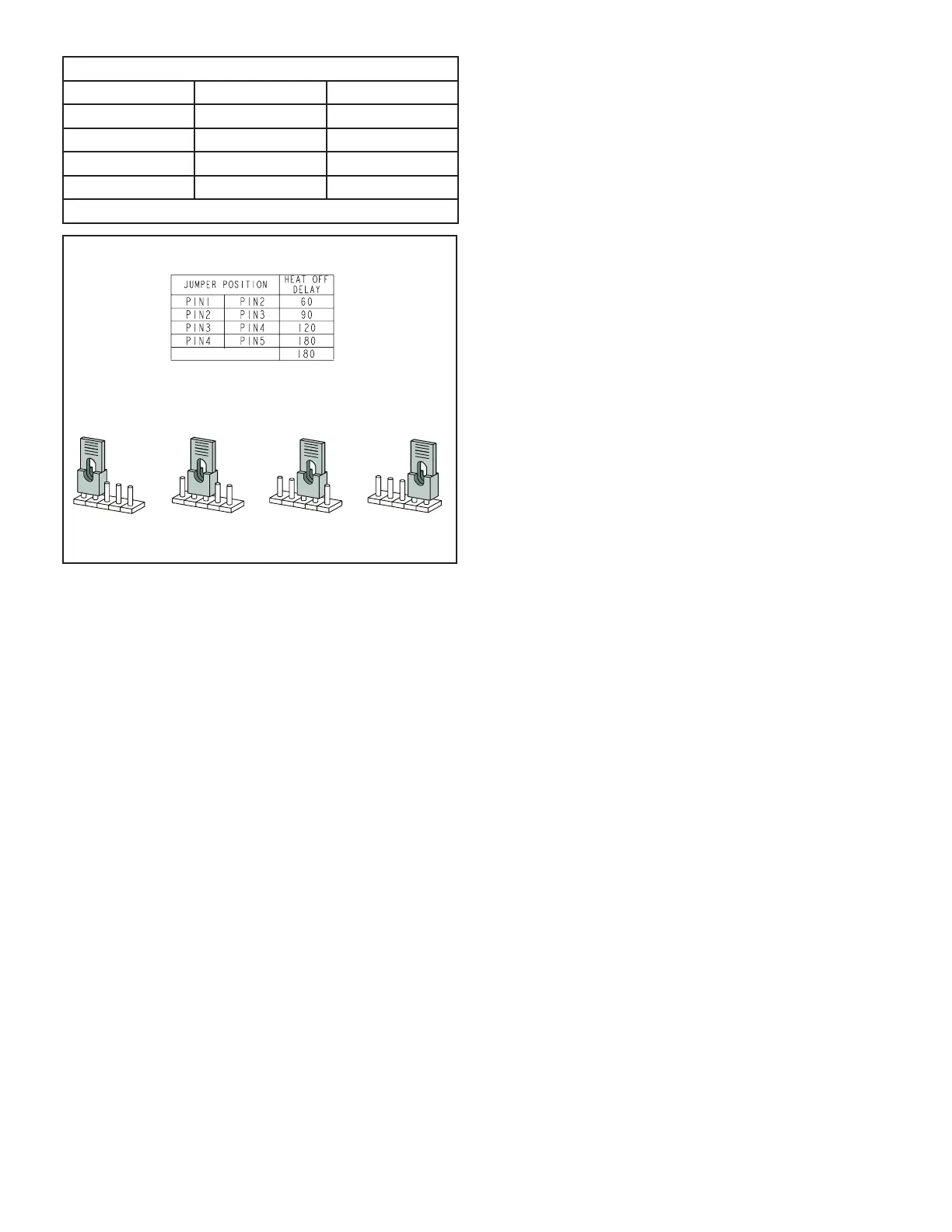

HEAT FAN‐OFF TIME IN SECONDS

To adjust fan-off timing, reposition jumper across pins to

achieve desired setting.

NO JUMPER

60

90

120

180

60

90

120

180

60

90

120

180

60

90

120

180

60 Second

off Time

90 Second

off Time

120 Second

off Time

180 Second

off Time

Figure 24

Constant Torque Motor

ML180DFE units are equipped with a permanent magnet-

ic indoor blower motor that provides constant torque. The

-

nal common. Each tap requires 24 volts to be energize.

Flame Rollout Switches

These manually reset switches are located on the burner

box.

Input Voltage Requirements

The circuit is designed to be operated with AC voltage. A

voltage of 12 to 33VAC is required to energize the motor.

Expected current draw will be less than 20mA.

Electrical

1 - Check all wiring for loose connections.

2 - Check for the correct voltage at the furnace operating).

Correct voltage is 120VAC + 10%

3 - Check amp-draw on the blower motor with blower

access panel in place.

Motor Nameplate__________Actual__________

Blower Speeds

Follow the steps below to change the blower speeds.

1 -

2 - Remove blower access panel.

3 - Disconnect existing speed tap at integrated control

speed terminal.

NOTE - Termination of any unused motor leads

must be insulated.

4 - Place unused blower speed tap on integrated control

“PARK” terminal or insulate.

5 - Refer to blower speed selection chart on unit wiring

diagram for desired heating or cooling speed. See

Blower performance data beginning on the next

page.

6 - Connect selected speed tap at integrated control

speed terminal.

7 - Resecure blower access panel.

8 - Turn on electrical power to furnace.

9 - Recheck temperature rise.

Electronic Ignition

The integrated control has an added feature of an internal

Watchguard control. The feature serves as an automat-

ic reset device for integrated control lockout caused by

ignition failure. This type of lockout is usually due to low

gas line pressure. After one hour of continuous thermostat

demand for heat, the Watchguard will break and remake

thermostat demand to the furnace and automatically reset

the integrated control to begin the ignition sequence.

Loading...

Loading...