Page 8

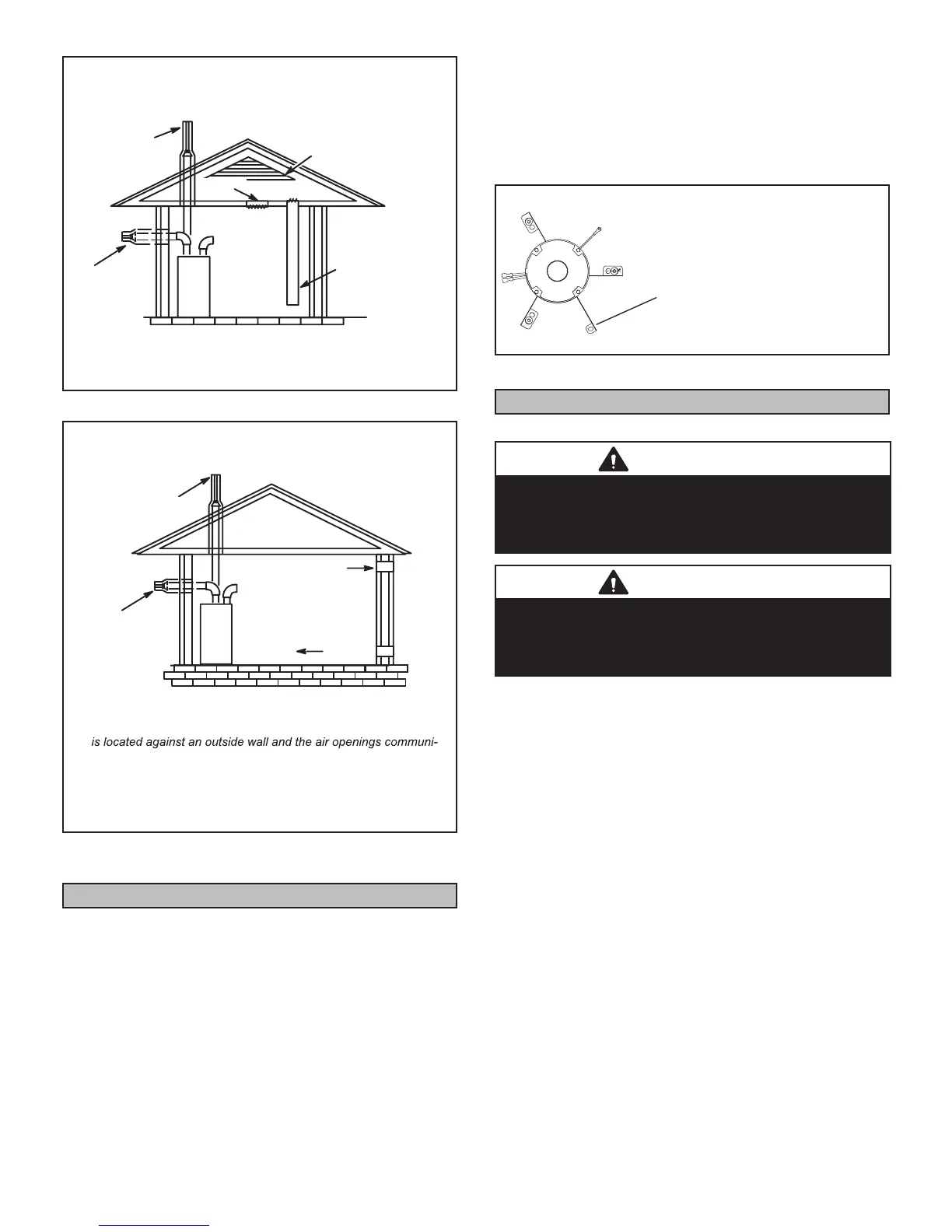

EQUIPMENT IN CONFINED SPACE - ALL AIR FROM OUTSIDE

(All Air Through Ventilated Attic)

NOTE-The inlet and outlet air openings shall each have a free area of

at least one square inch per 4,000 Btu (645mm

2

per 1.17kW) per hour

of the total input rating of all equipment in the enclosure.

OUTLET

AIR

VENTILATION LOUVERS

(Each end of attic)

INLET AIR

(Ends 12” above

bottom)

ROOF TERMINATED

EXHAUST PIPE

SIDE WALL

TERMINATED

EXHAUST PIPE

(ALTERNATE

LOCATION)

FURNACE

FIGURE 8

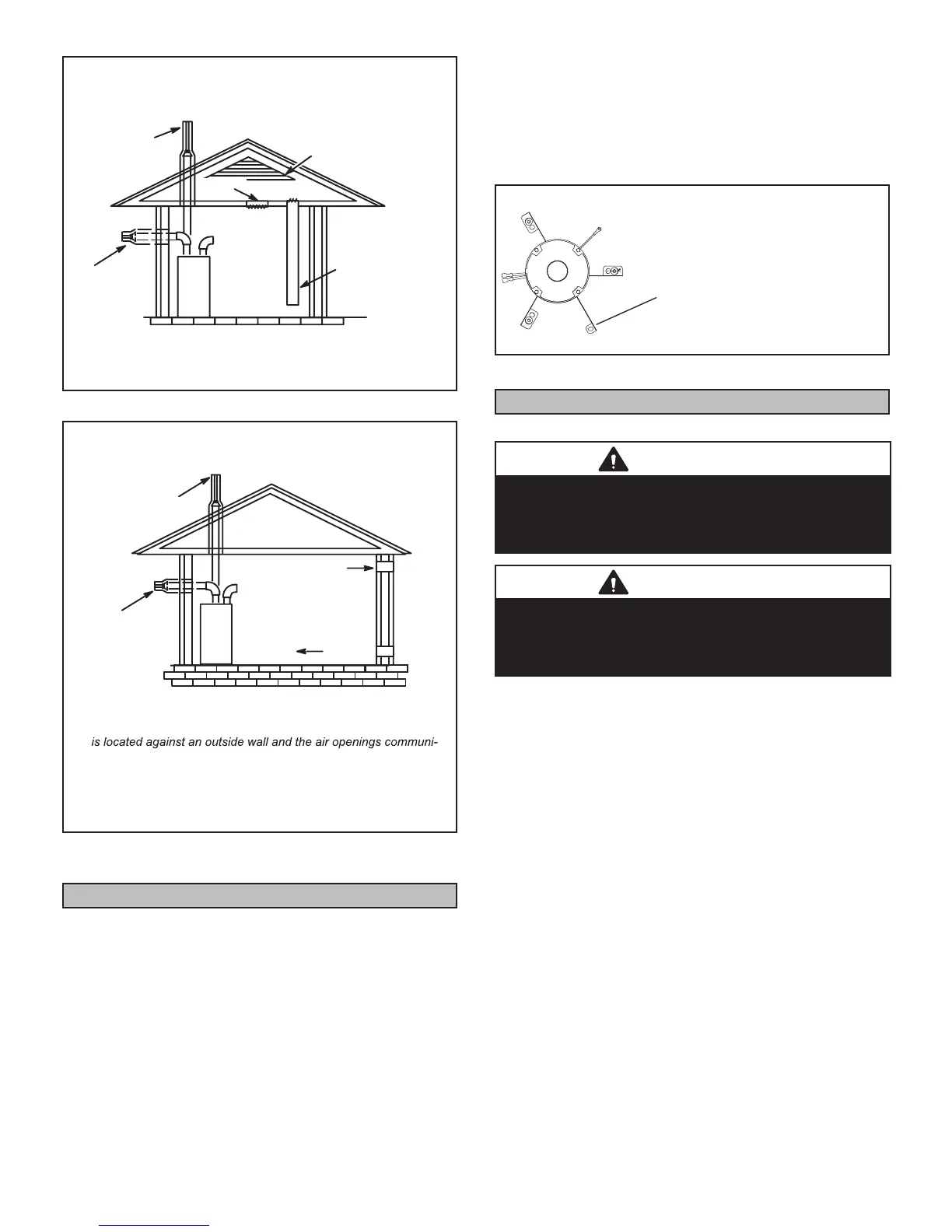

EQUIPMENT IN CONFINED SPACE -

ALL AIR FROM OUTSIDE

OUTLET AIR

INLET AIR

NOTE-Each air duct opening shall have a free area of at least one

square inch per 2,000 Btu (645mm

2

per .59kW) per hour of the total

input rating of all equipment in the enclosure. If the equipment room

cate directly with the outdoors, each opening shall have a free area

of at least 1 square inch per 4,000 Btu (645mm

2

per 1.17kW) per

hour of the total input rating of all other equipment in the enclosure.

ROOF TERMINATED

EXHAUST PIPE

SIDE WALL

TERMINATED

EXHAUST PIPE

(ALTERNATE

LOCATION)

FURNACE

FIGURE 9

Shipping Bolt Removal

Units with 1/3HP and 1/2HP blower motors are equipped

with three exible legs and one shipping leg. See gure

10. In some units with 1/3HP blower motor, the shipping

leg is exible with rubber mounting grommets similar to

the other three mounting legs and require no modication.

The rest of the units with 1/3HP and 1/2HP blower motors

(these blower motor housings will be tagged) have a rigid

shipping leg equipped with a shipping bolt and at white

plastic washer. The bolt and washer must be removed

before the furnace is placed into operation. After the

bolt and washer have been removed, the rigid leg will not

touch the blower housing.

RIGID LEG

(Remove shipping bolt

and washer)

Blower motor with three exible legs and one

rigid shipping leg. Blower motor housings

will be tagged for shipping bolt removal

FIGURE 10

Installation - Setting Equipment

WARNING

Do not connect the return air duct to the back of the

furnace. Doing so will adversely affect the operation of

the safety control devices, which could result in personal

injury or death.

WARNING

Blower access panel must be securely in place when

blower and burners are operating. Gas fumes, which

could contain carbon monoxide, can be drawn into living

space resulting in personal injury or death.

Upow Applications

The ML193UH gas furnace can be installed as shipped

in the upow position. Refer FIGURE 12 for clearances.

Select a location that allows for the required clearances

that are listed on the unit nameplate. Also consider gas

supply connections, electrical supply, vent connection,

condensate trap and drain connections, and installation

and service clearances [24 inches (610 mm) at unit front].

The unit must be level from side to side. Unit may be posi-

tioned from level to 1/2” toward the front to aid in draining.

See FIGURE 11.

Allow for clearances to combustible materials as indicated

in the unit nameplate.

Loading...

Loading...