Page 14

B-Heating Components

Combustion air inducer (B6), primary limit control (S10),

SureLight ignitor, burners, flame rollout switch (S47), gas

valve (GV1), combustion air prove switch (S18), and clam

shell heat exchangers are located in the heating compart

ment. The heating compartment can be accessed by re

moving the burner access panel.

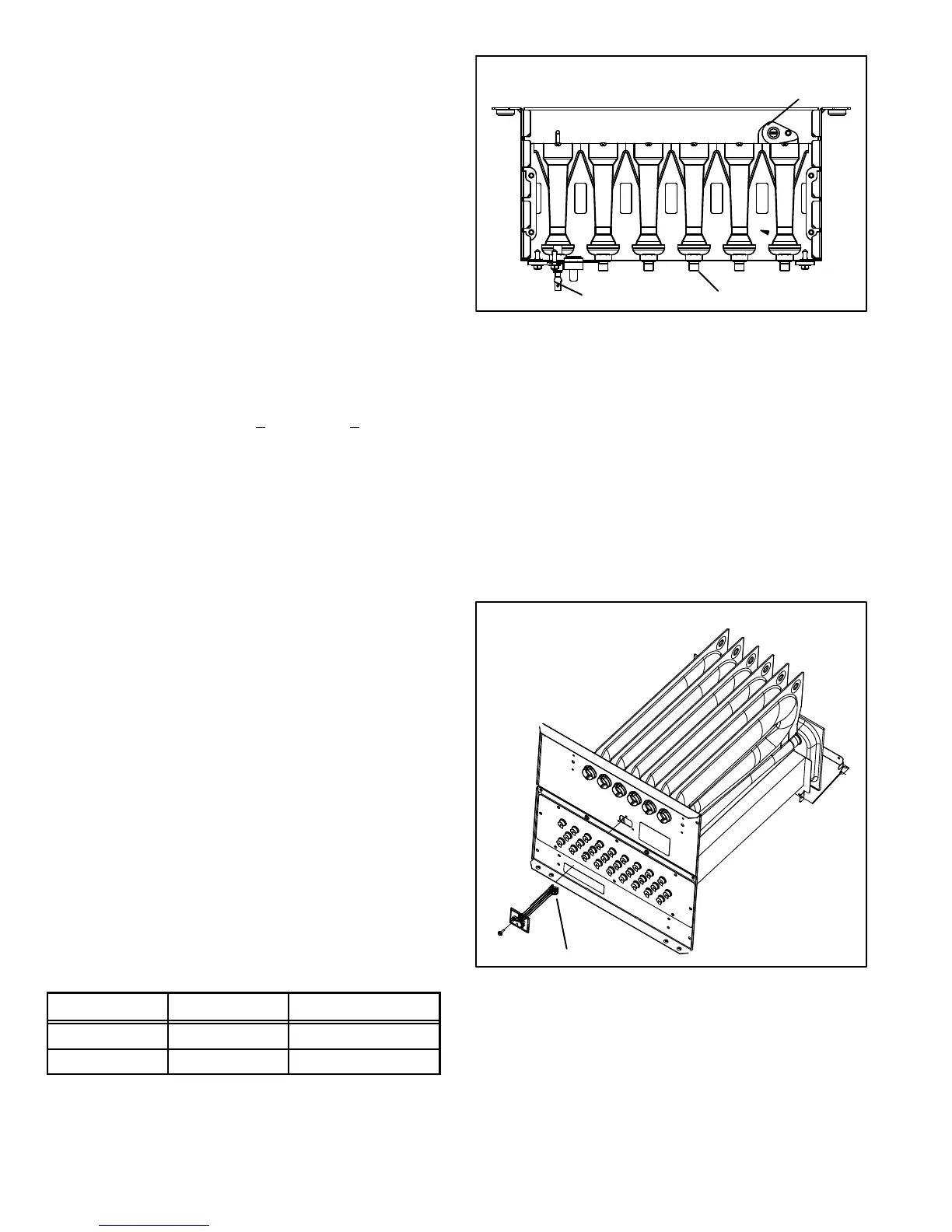

1. Flame Rollout Switches (Figure 10)

Flame rollout switches S47 are SPST N.C. high tempera

ture limits located on the top left and bottom right of the front

buner box plate. S47 is wired to the burner ignition control

A92. When either of the switches sense flame rollout (indi

cating a blockage in the combustion passages), the flame

rollout switch trips, and the ignition control immediately

closes the gas valve. Switch S47 in all ML195UH units is

factory preset to open at 210_F +

12_F (99_C + 6.7_C) on a

temperature rise. All flame rollout switches are manual re

set.

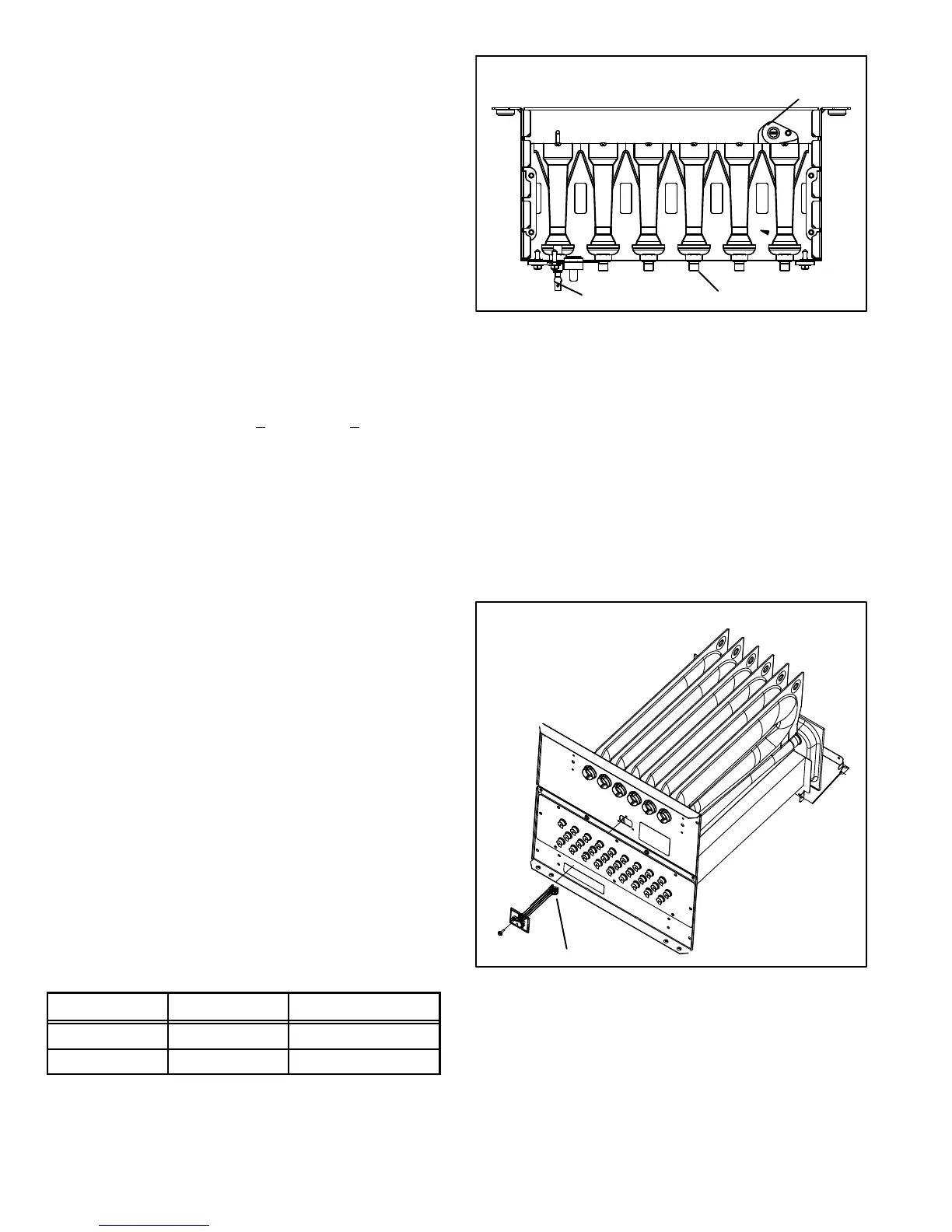

2. Primary Limit Control (Figure 12)

Primary limit (S10) used on ML195UH units is located in the

heating vestibule panel. When excess heat is sensed in the

heat exchanger, the limit will open. Once the limit opens,

the furnace control energizes the supply air blower and de-

energizes the gas valve. The limit automatically resets

when unit temperature returns to normal. The switch is fac

tory set and cannot be adjusted. For limit replacement re

move wires from limit terminals, remove mounting screws,

rotate limit switch 90 degrees and slowly remove from the

vestibule panel. Install replacement limit with same care.

3. Burners (Figure 11)

All units use inshot burners. Burners are factory set and do

not require adjustment. Burners can be removed as an as

sembly for service. Burner maintenance and service is de

tailed in the MAINTENANCE section of this manual. Each

burner uses an orifice which is precisely matched to the

burner input. See table 7 for orifice size. The burner is sup

ported by the orifice and will easily slide off for service. A

flame retention ring in the end of each burner maintains

correct flame length and shape and keeps the flame from

lifting off the burner head.

TABLE 7

Gas Orifice Size

Unit Fuel Orifice Size

All Natural 0.063

All L.P./Propane 0.0340

FIGURE 11

Burner Detail Top View

FLAME SENSOR

IGNITOR

ORIFICES

4. Heat Exchanger (Figure 12)

ML195UH units use an aluminized steel primary and stain

less steel secondary heat exchanger assembly. Heat is

transferred to the air stream from all surfaces of the heat

exchanger. The shape of the heat exchanger ensures

maximum efficiency.

The combustion air inducer pulls fresh air through the burn

er box. This air is mixed with gas in the burners. The gas /

air mixture is then burned at the entrance of each clam

shell. Combustion gases are then pulled through the pri

mary and secondary heat exchangers and exhausted out

the exhaust vent pipe.

FIGURE 12

Primary Limit Location and Heat Exchanger

Install limit face down

5. Gas Valve (GV1)

The ML195UH uses an internally redundant valve to as

sure safety shut‐off. If the gas valve must be replaced, the

same type valve must be used.

Loading...

Loading...