Page 20

Pressure Switch Check

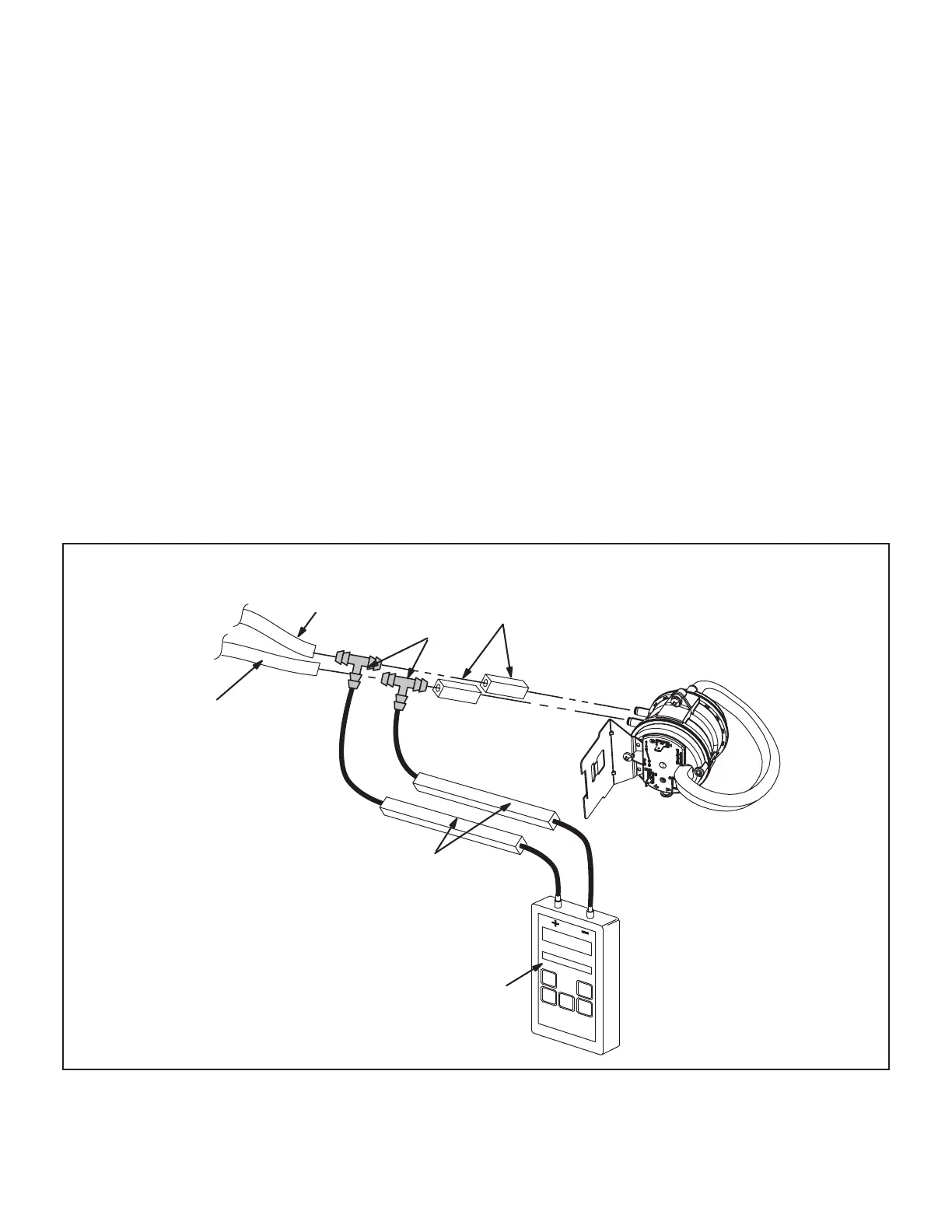

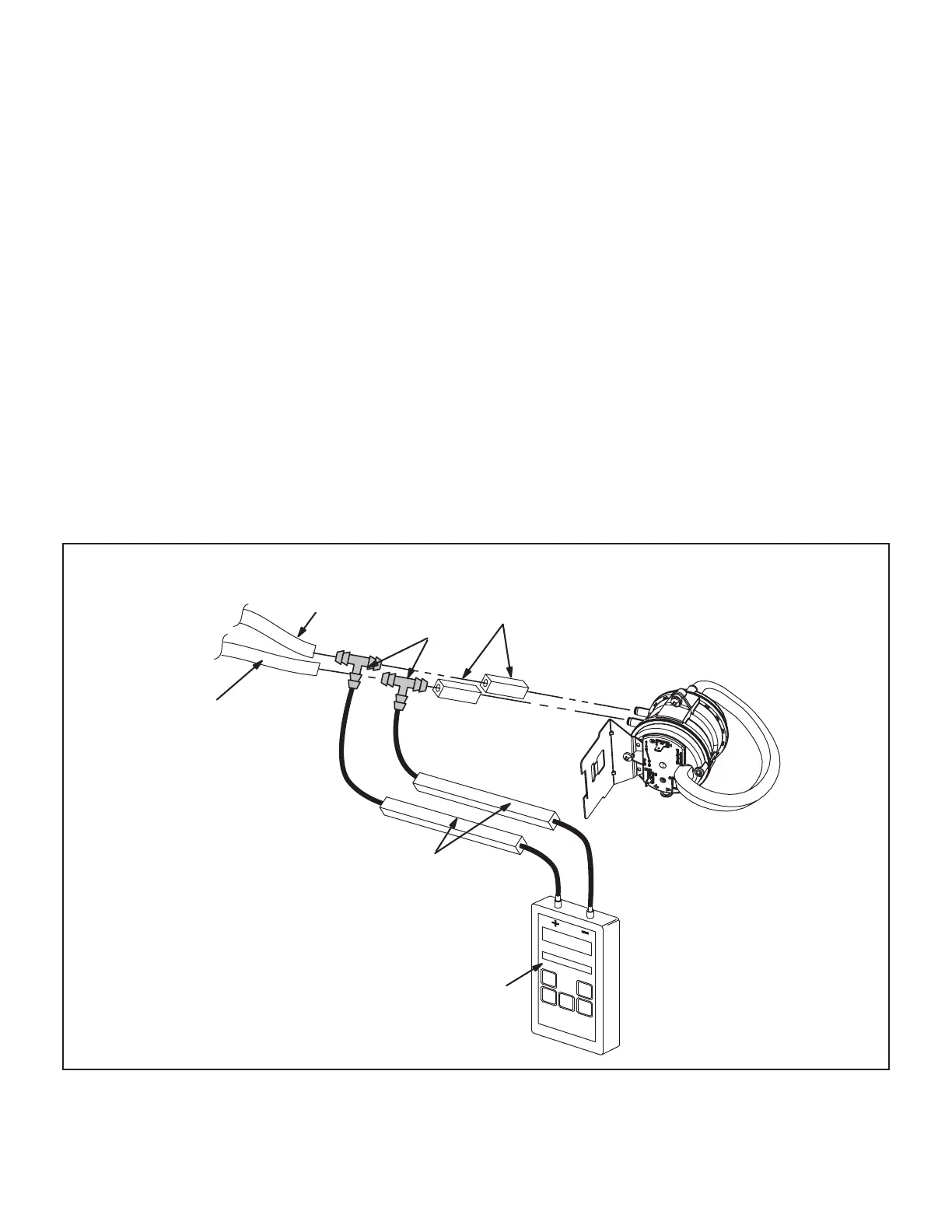

To check pressure switch dierential, refer to FIGURE 15

and use the provided ttings and tubing to follow the steps

below.

1 - Remove thermostat demand and allow unit to cycle

o.

2 - Remove the tubing from the negative side (red

and black or red) and positive side (black) of the

pressure switch (leave both connected to cold end

header box).

3 - Take the 2” length square tubing and connect to the

positive (+) side of the pressure switch. Take the 10”

length square tubing and tee into the tubing from

the positive side of the cold end header box and

the other side of the 2” square tubing. Connect the

other end of the 10” square tubing the the positive

(+) side of the measuring device.

4 - Take a second piece the 2” length square tubing

and connect to the negative (-) side of the pressure

switch. Take a second piece of 10” length square

tubing and tee into the tubing from the negative (-)

side of the cold end header box and the other side

of the 2” square tubing. Connect the other end of

the 10” square tubing the the negative (-) side of the

measuring device.

5 - Operate unit and observe manometer reading.

Readings will change as heat exchanger warms.

a. Take one reading immediately after start-up.

b. Take a second reading after unit has reached steady

state (approximately 5 minutes). This will be the pressure

dierential.

The pressure dierential should be at least 0.15”

greater than those listed in the table 8. Readings in

table are the set points or “break points”.

6 - Remove thermostat demand and allow to cycle o.

7 - Replace original pressure switch tubing.

NOTE - Pressure dierential values (set point)

in table are the ”break”, or ”open” specications.

”Make”, or ”close” pressure dierentials are 0.15”

greater than the set points listed in table.

PRESSURE SWITCH CHECK

Black Tubing

(positive +)

Red and Black

or Red Tubing

(negative −)

Tee

2” long Square

Tubing

Measuring Device

10” Long Square Tubing

FIGURE 15

Loading...

Loading...