• 20 •

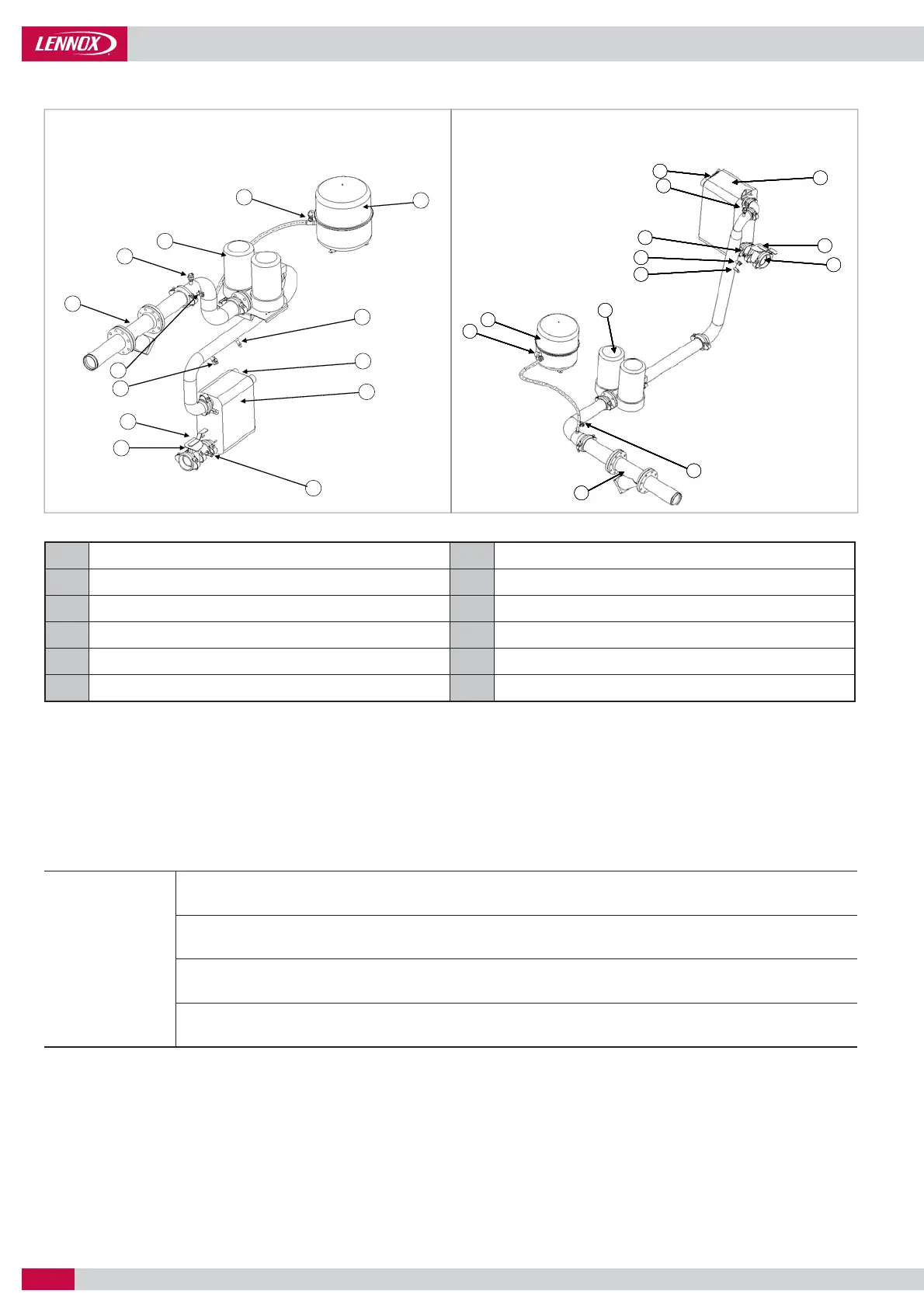

01 07

02 08

03 09

04 10

05 11

06 12

08

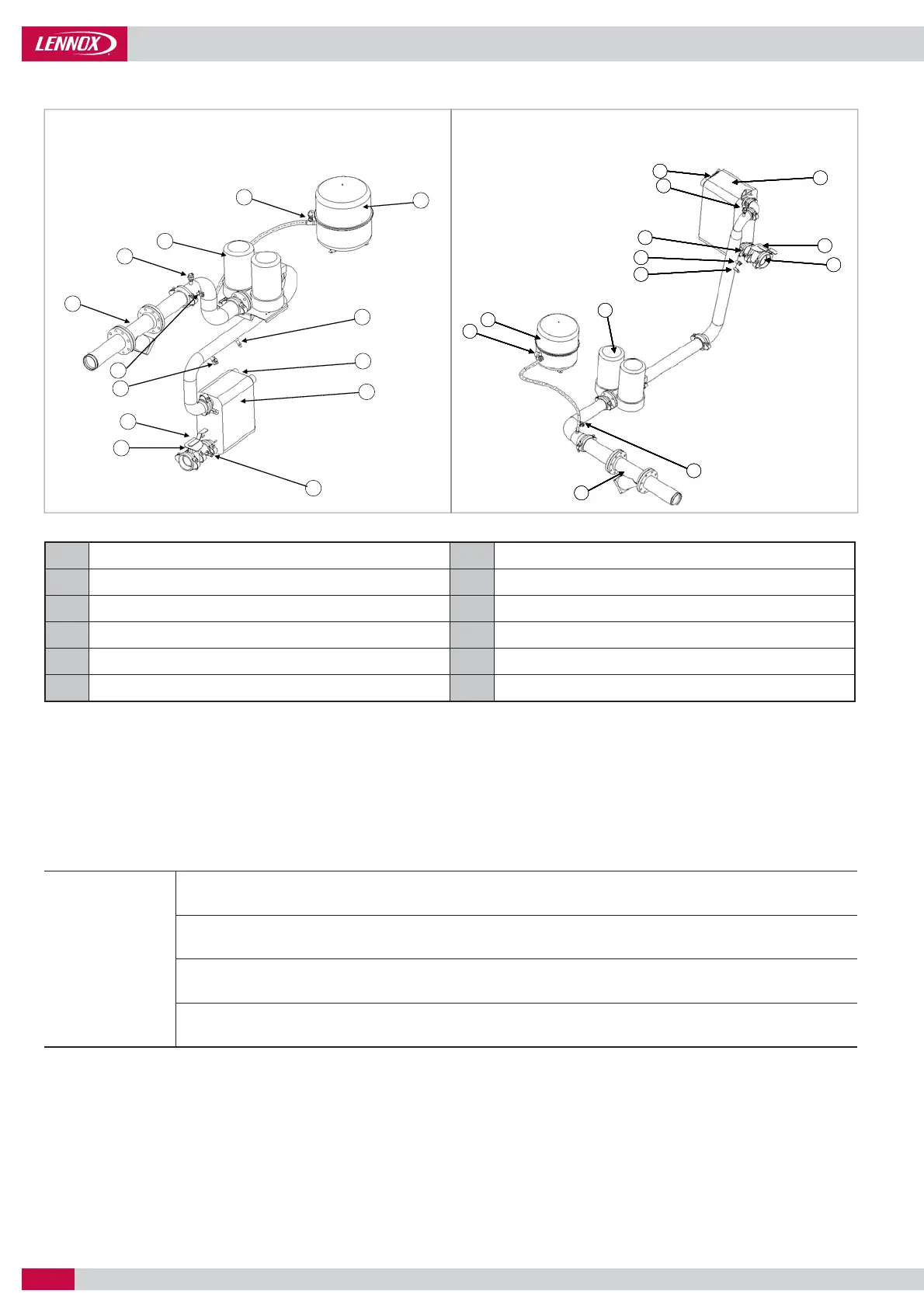

01

02

04

05

07

09

10

11

12

03

03

06

08

0101

0202

0404

06

05

0707

09

10

1111

1212

0303

0303

NAC/NAH

200 - 230 - 270 - 300

NAC 340 - 380 - 420 - 480 - 540 - 600 - 640

NAH 340 - 380 - 420 - 480

V

Q

Dt

Application Guide / NEOSYS-AGU-1801-E

HYDRAULIC DATA

UNIT WITH HYDRAULIC MODULE

Water fi lter (item supplied loose) Electronic fl ow switch

Air purge Plate heat exchanger

Pressure tap Setting valve

Pump Pressure tap and drain valve

Safety valve with manometer Return temperature sensor

Expansion vessel Supply temperature sensor

IN

OUT

Vmini = 86 x Q / (Nstages x Dt)

Where :

Minimum water content of the installation

Cooling capacityof the chiller

Nstage Number of control steps available in the unit

Maximum acceptable temperature rise (Dt = 6°c for an air conditioning application)

Important note: In case NEOSYS is used in air-conditioning applications with a short water system (e.g. NEOSYS application with air

handling units) or in case NEOSYS is used for industrial process cooling, it is mandatory to use a buffer tank.

MINIMUM WATER CONTENT OF AN INSTALLATION

Thanks to multi step capacity control and smart anti-short compressor cycling, NEOSYS can work with minimum water loop volume

as defi ned here below. This can eliminate the need for a buffer tank in most of air-conditioning applications (e.g. NEOSYS application

with fan-coil units).

Loading...

Loading...